Thermal compounded steel-aluminum compounded conductive rail and manufacturing method

A steel-aluminum composite and manufacturing method technology, which is applied to power rails and other directions, can solve the problems of low productivity of steel-aluminum composite conductor rails, low contact resistance between steel and aluminum, and low yield, and achieves high yield and steel-aluminum contact resistance. Small, productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

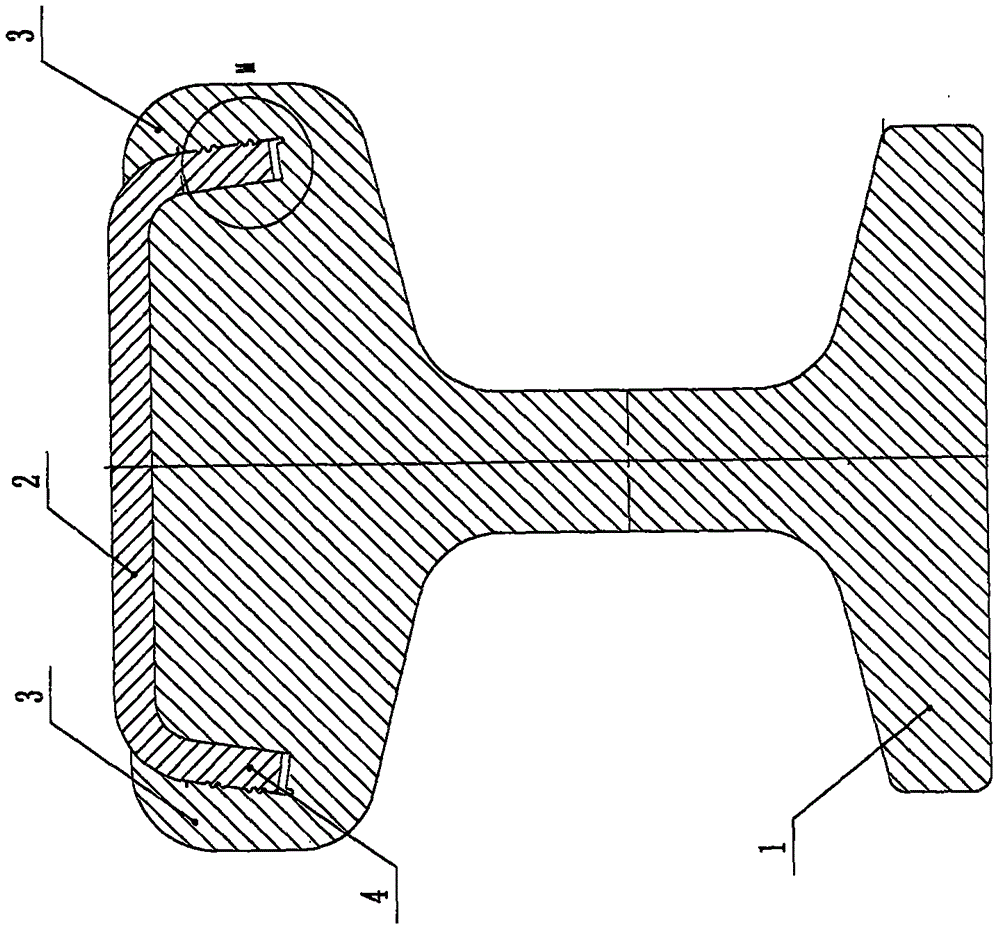

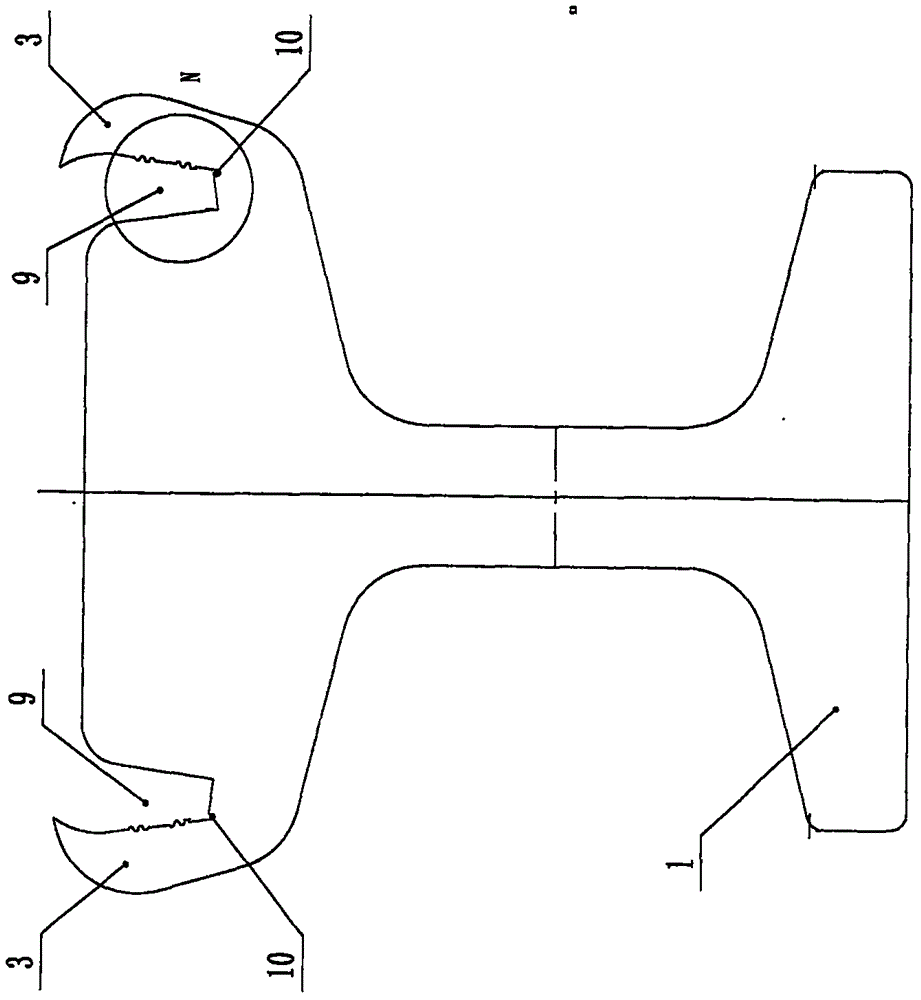

[0022] figure 1 It is a cross-sectional view of a thermally composited steel-aluminum composite conductor rail. The top of the I-shaped aluminum rail 1 is a stainless steel channel 2, and the upper surface of the aluminum rail 1 is closely attached to the inner surface of the steel channel 2. The two lugs 3 on both sides above the aluminum rail 1 tightly press the outer sides of the two sides 4 of the steel channel 2 .

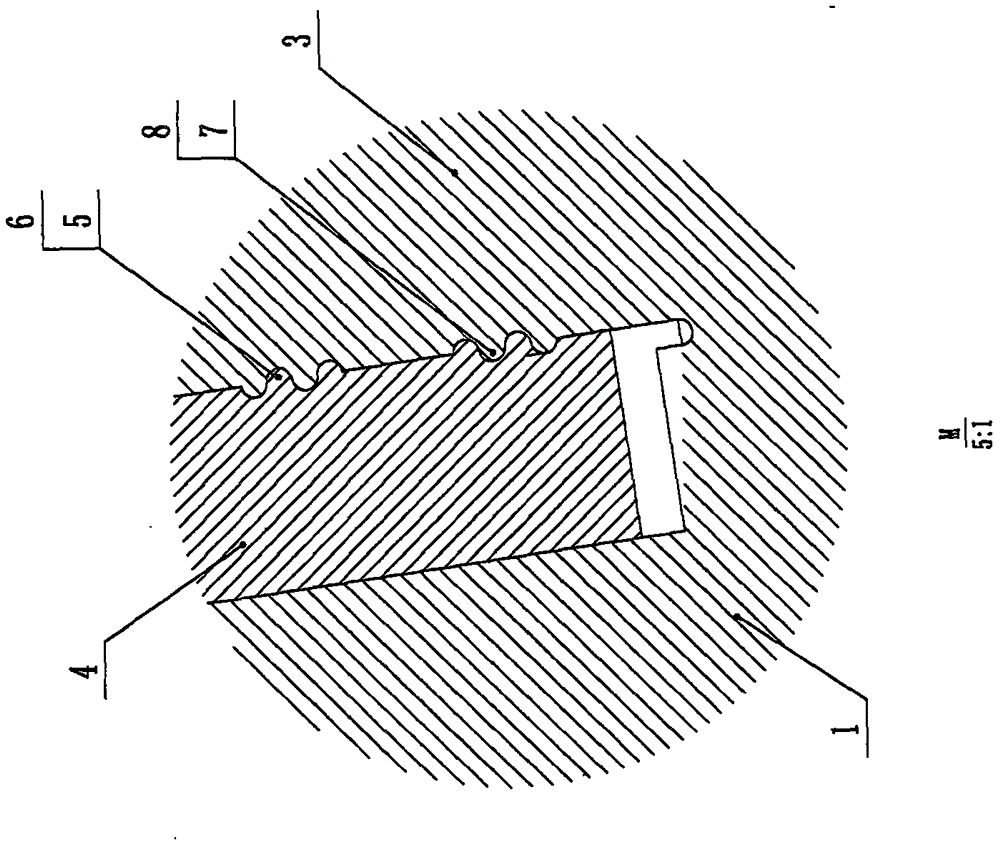

[0023] figure 2 for figure 1 Partial enlarged view of the junction of aluminum lug 3 and steel side 4 at the upper right. The knurled rib 5 on the side 4 of the steel channel 2 coincides with the groove 6 of the lug 3 of the aluminum rail 1, and the knurled groove 7 on the steel side 4 coincides with the rib of the lug 3 of the aluminum rail 1 The 8 phases overlap, forming wavy intersecting grooves and ribs on the interface between the two, so that the steel and aluminum are integrated, and there is a high bonding strength in three directions.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com