Chisel holder system

A technology of tool holders and components, applied in the direction of slitting machinery, cutting machinery, drilling equipment, etc., can solve the problems of expensive assembly and trouble, and achieve the effect of preventing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

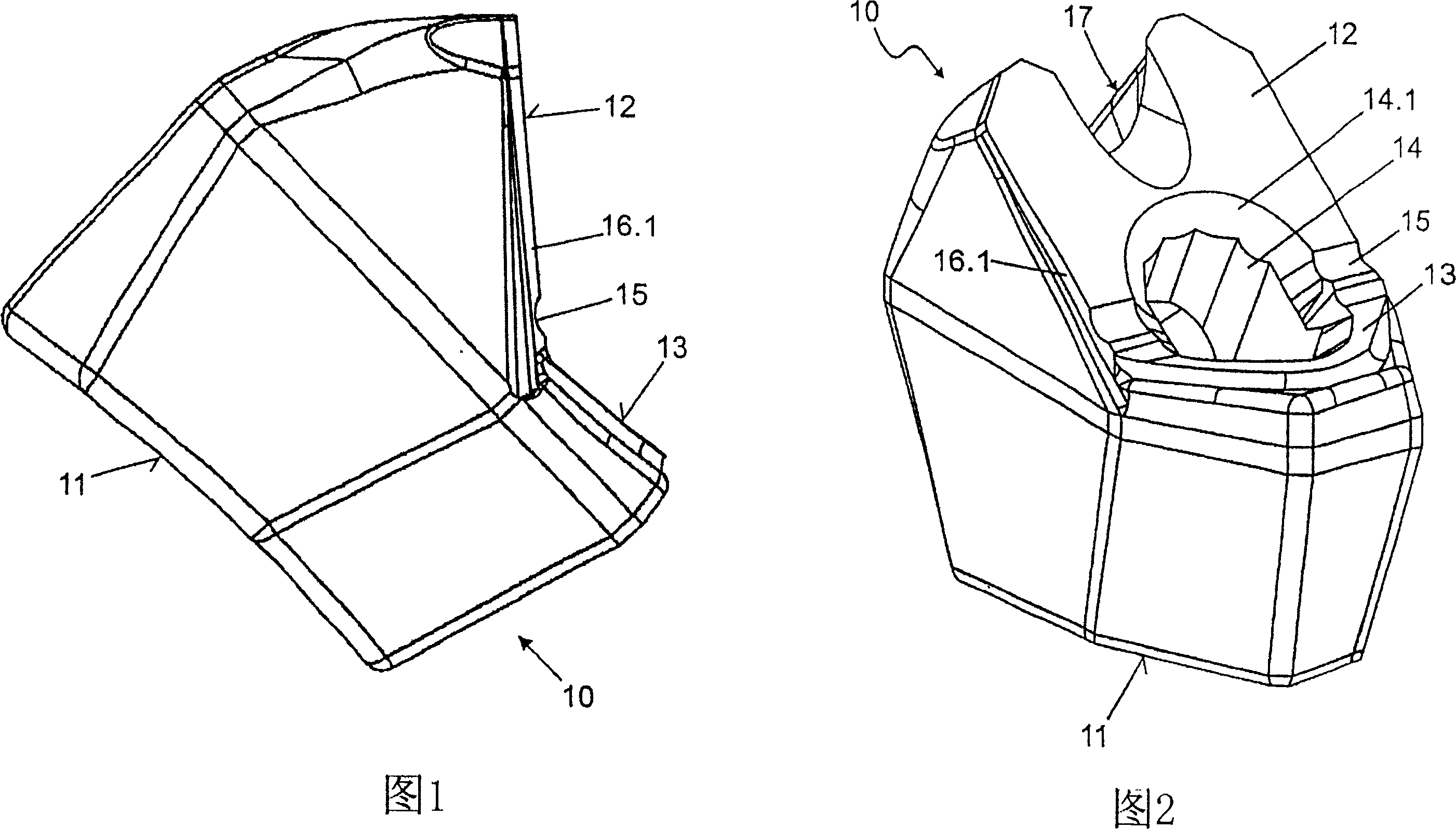

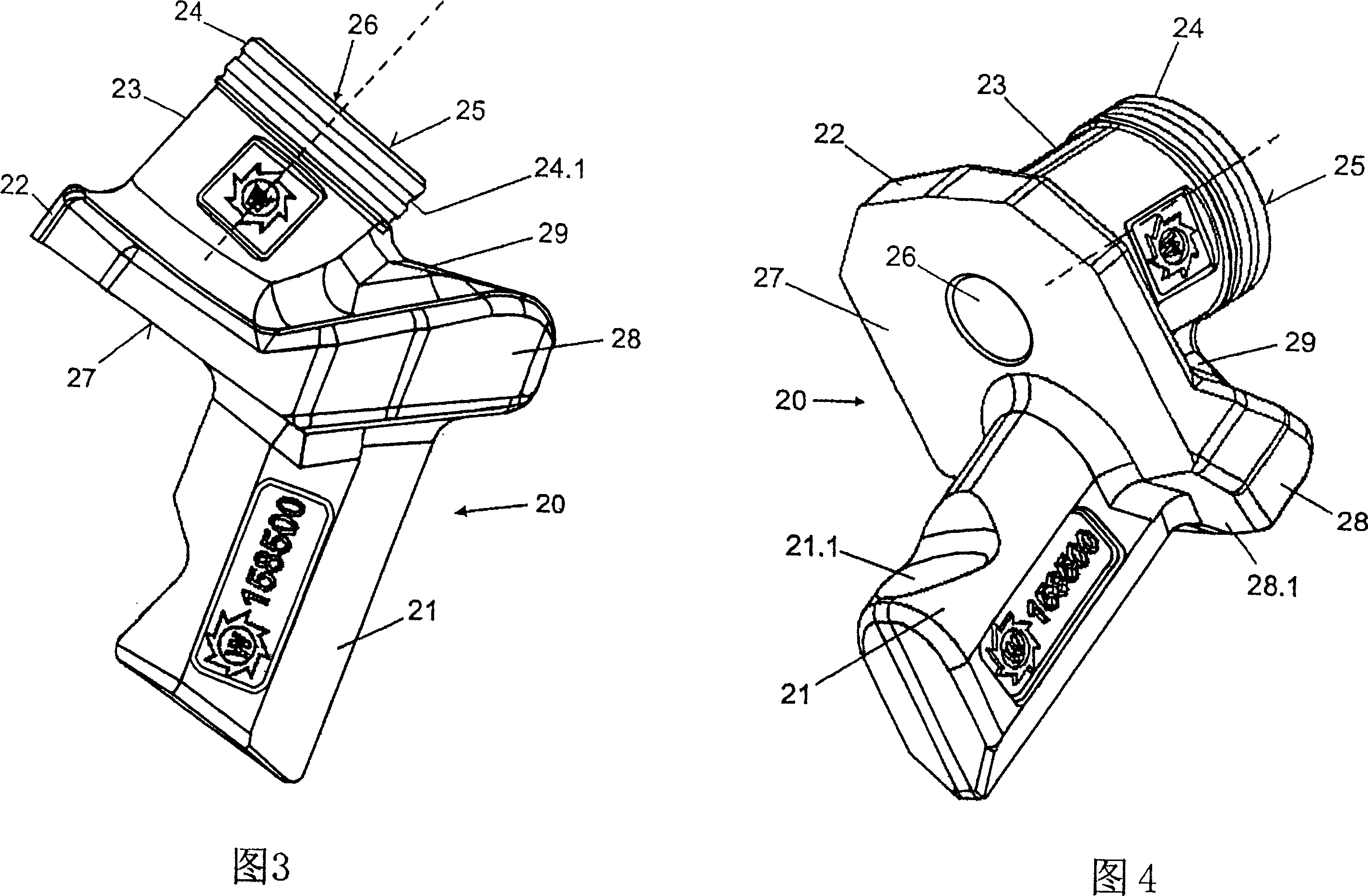

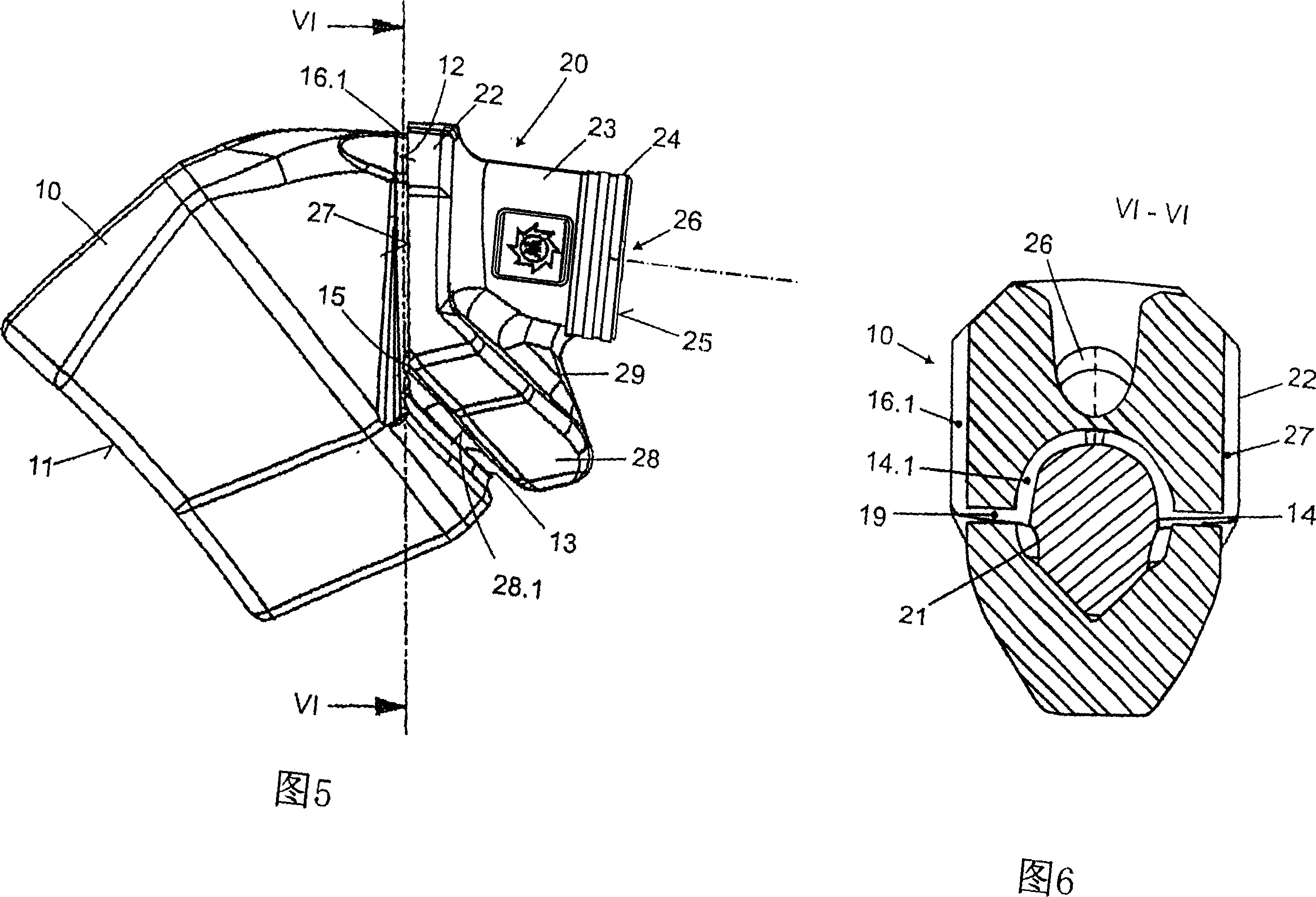

[0020] FIGS. 1 and 2 show a base part 10 which is fastened via curved contact surfaces 11 to the outer circumference of a milling roller tube, such as a road milling machine. Its base part 10 has a bearing surface 12 on which a projection 13 adjoins at an angle. In the region of the transition from its projection 13 to the bearing surface 12 . An insertion receptacle 14 constituted by a notch is formed on the base member 10 . Its plug-in receptacle 14 extends via a cross-sectional extension 14.1 to the bearing surface 12 or projection 13 .

[0021] The bearing surface 12 is formed by a raised portion 16.1. For this purpose, its raised part 16 . 1 has, in a direction perpendicular to the bearing surface 12 , a cross-sectional dimension equal to that of the bearing surface 12 . In the region of the transition from its projection 13 to the bearing surface 12 , the bearing surface 12 is terminated by a depression 15 . The concave portion 15 is formed by grooves on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com