Active loop heat sink device with atomizer

A heat-dissipating device and active technology, applied in the field of heat-dissipation technology, can solve the problems of non-compliance with product miniaturization, increase the overall volume, etc., and achieve the effects of improving performance, reducing volume, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

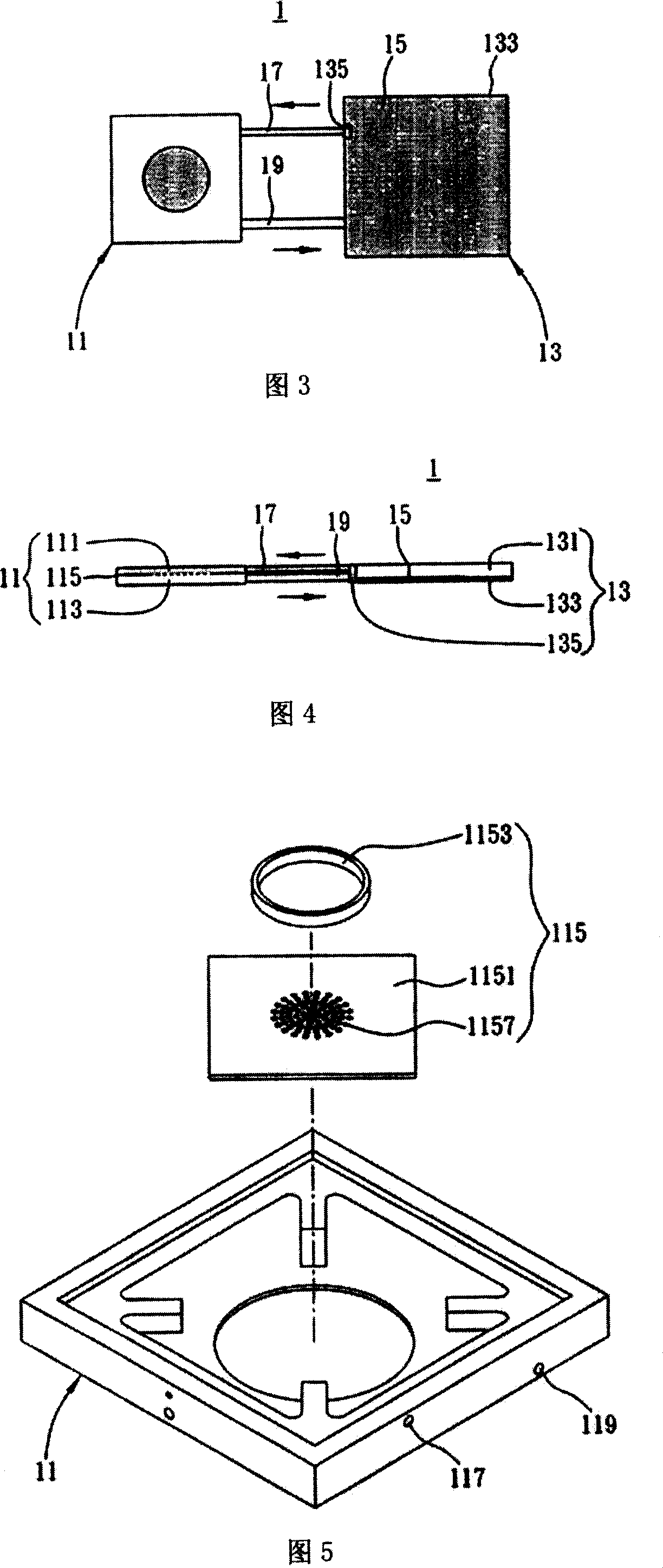

[0033] 3 to 6B are drawings drawn according to Embodiment 1 of the active loop heat sink with atomizer of the present invention.

[0034]Fig. 3 is a schematic diagram of the active loop type cooling device with atomizer of the present invention, as shown in the figure, the active loop type cooling device 1 with atomizer is applied in heat source and heat sink (not shown) The heat conduction between the active loop type cooling device 1 with the atomizer includes an evaporation cavity 11, a condensation cavity 13 connected to the evaporation cavity 11, and a flow between the evaporation cavity 11 and the condensation cavity 13 Between the working fluid 15. Meanwhile, in this embodiment, the first channel 17 and the second channel 19 connected between the evaporation cavity 11 and the condensation cavity 13 are provided. In addition, in this embodiment, the evaporation chamber 11 and the condensation chamber 13 communicate with the first passage 17 and the second passage 19, bu...

Embodiment 2

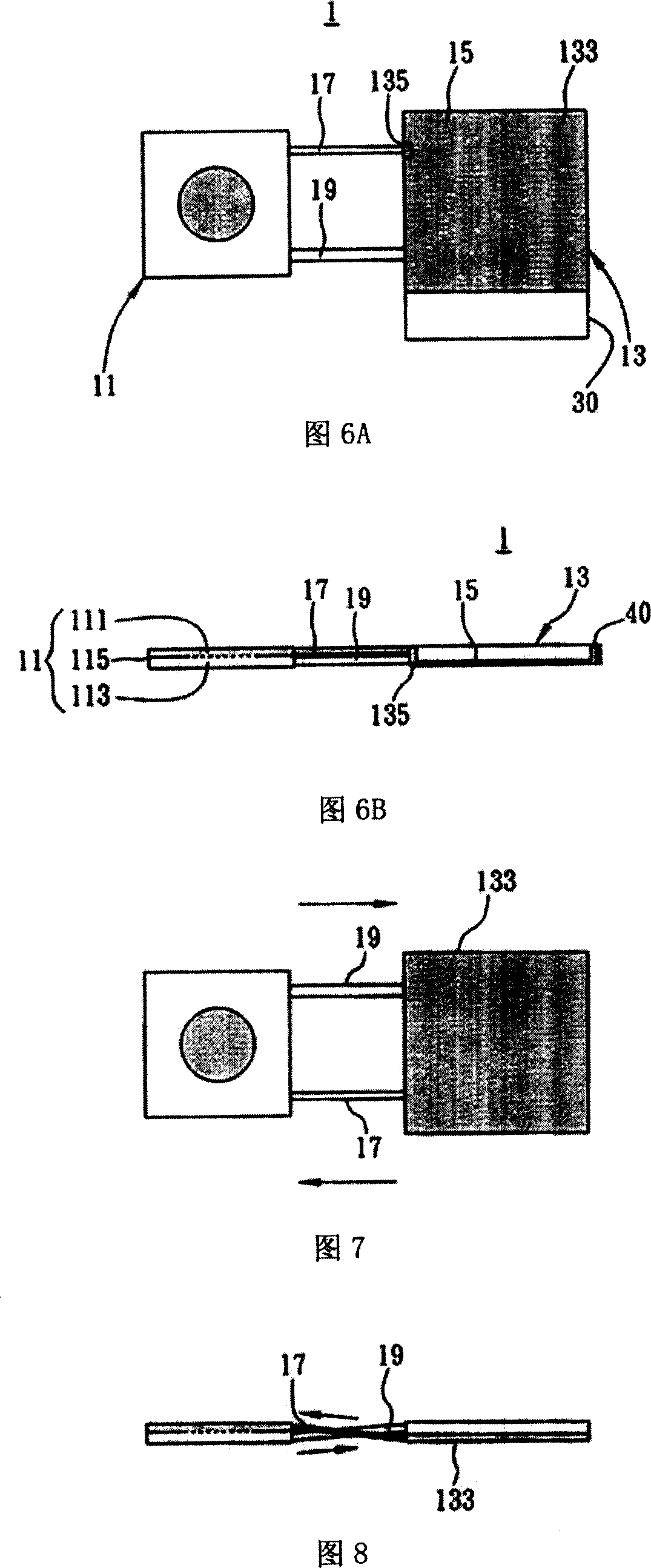

[0048] Figure 7 and Figure 8 are drawings drawn according to Embodiment 2 of the active loop type cooling device with atomizer of the present invention, wherein the same or similar components as those of Embodiment 1 above are denoted by the same or similar component symbols , and omitted the detailed description to make the explanation of this case clearer and easier to understand.

[0049] The biggest difference between this embodiment and embodiment 1 is that the first channel and the second channel of embodiment 1 are arranged in parallel, and the first channel and the second channel of embodiment 2 are arranged alternately.

[0050] As shown in FIG. 7 and FIG. 8 , the first channel 17 and the second channel 19 are alternately arranged, and the first channel 17 is directly connected to the capillary structure 133 , and the capillary structure 135 provided in the first embodiment can be omitted.

[0051] To sum up, in the active loop cooling device with an atomizer of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com