Plant fiber material acidolysis solution electrodialysis detoxification process and device

A technology of plant fiber and acid hydrolyzate, which is applied in the fields of bioenergy and green chemical industry, can solve problems such as low cost, and achieve the effects of small loss of reducing sugar, easy control, and good detoxification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

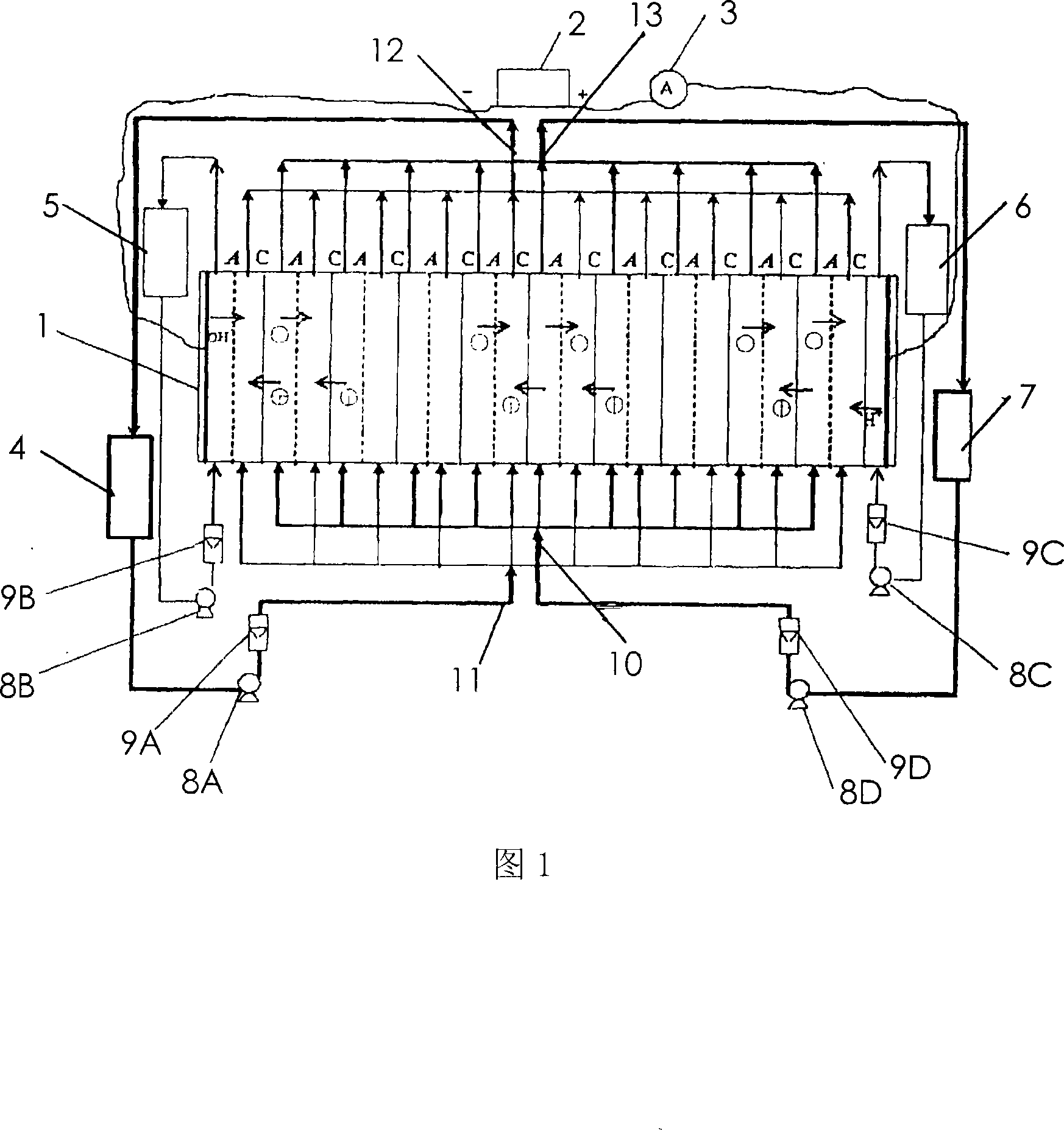

Image

Examples

Embodiment 1

[0021] The straw is cut, dedusted and crushed to 40 mesh, and added to a sulfuric acid solution with an acid concentration of 7%, and the liquid-solid ratio of the solution to the plant fiber raw material is 5:1;

[0022] (2) Raise the temperature to 120° C. and maintain the temperature for 2 hours.

[0023] (3) The liquid-solid mixture obtained above is filtered, and 1L of acid hydrolyzate is added in the weak room tank 7; the concentration is 0.01mol / L sulfuric acid solution 1L in the concentrated room tank 4, and the concentration of 0.05mol / L is added in the cathode room tank. 0.75 L of sodium hydroxide solution in L; add 0.75 L of sulfuric acid solution with a concentration of 0.05 mol / L in the anode chamber tank.

[0024] (4) Turn on the pumps 8A-8D to circulate the solution in the concentrated chamber and the weak chamber in the electrodialyzer 1, and adjust the flow meter so that the solution flow rate in the concentrated chamber, the weak chamber, the anode chamber an...

Embodiment 2

[0028] The bagasse is cut, dedusted and crushed to 40 meshes, and then added to a hydrochloric acid solution with an acid concentration of 0.5%, and the liquid-solid ratio of the solution to the plant fiber raw material is 20:1;

[0029] (2) Raise the temperature to 80° C. and maintain the temperature for 10 hours.

[0030](3) The above gained liquid-solid mixture is filtered, and 1L of acid hydrolyzate is added in the dilute chamber tank 7; Adding concentration is 0.01mol / L hydrochloric acid solution 1L in the concentration chamber tank 4, and adding concentration is 0.05mol / L in the cathode chamber tank 0.75 L of sodium hydroxide solution in L; add 0.75 L of sulfuric acid solution with a concentration of 0.05 mol / L in the anode chamber tank.

[0031] (4) Turn on the pumps 8A-8D to circulate the concentrated chamber, the dilute chamber and the solution in the electrodialyzer 1, adjust the flow meter so that the solution flow rate in the concentrated chamber, the dilute chambe...

Embodiment 3

[0035] The wheat straw is cut, dedusted and crushed to 40 meshes, and added to an acetic acid solution with an acid concentration of 0.65%, and the liquid-solid ratio of the solution to the plant fiber raw material is 15:1;

[0036] (2) Raise the temperature to 100° C. and maintain the temperature for 6 hours.

[0037] (3) The above gained liquid-solid mixture is filtered, and 1L of acid hydrolyzate is added in the dilute chamber tank 7; Adding concentration is 0.01mol / L hydrochloric acid solution 1L in the concentration chamber tank 4, and adding concentration is 0.05mol / L in the cathode chamber tank 0.75 L of sodium hydroxide solution in L; add 0.75 L of sulfuric acid solution with a concentration of 0.05 mol / L in the anode chamber tank.

[0038] (4) Turn on the pumps 8A-8D to circulate the concentrated chamber, the dilute chamber and the solution in the electrodialyzer 1, adjust the flow meter so that the solution flow rate in the concentrated chamber, the dilute chamber, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com