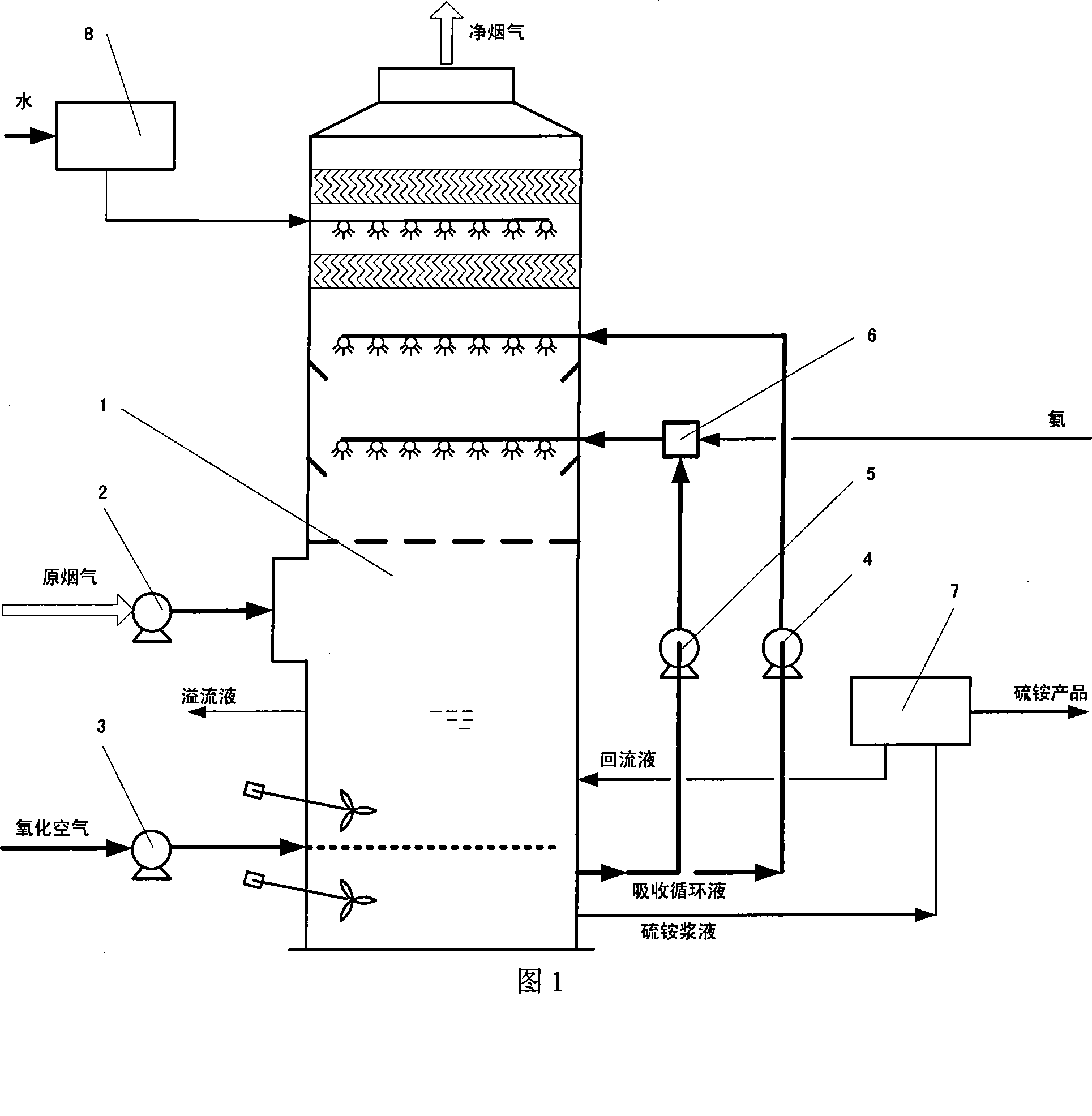

Method and device for reclaiming sulfur dioxide from countercurrent flue gas

A sulfur dioxide and recovery device technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of flue gas turning into waste residue, consumption of natural resources, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A 440T / h fluidized bed boiler, burning coal with a sulfur content of 1.5%, and a flue gas flow rate of 500,000 Nm 3 / hr, SO 2 The content is 3200mg / Nm 3 , the content of other pollutants in the flue gas is: dust = 80mg / Nm 3 , SO 3 =55mg / Nm 3 , HCl=35mg / Nm 3 , HF=20mg / Nm 3 , NOx=100mg / Nm 3 , the flue gas temperature is 120°C.

[0069] The raw material for sulfur dioxide absorption is an ammonia water mixture with an ammonia weight concentration of 18%.

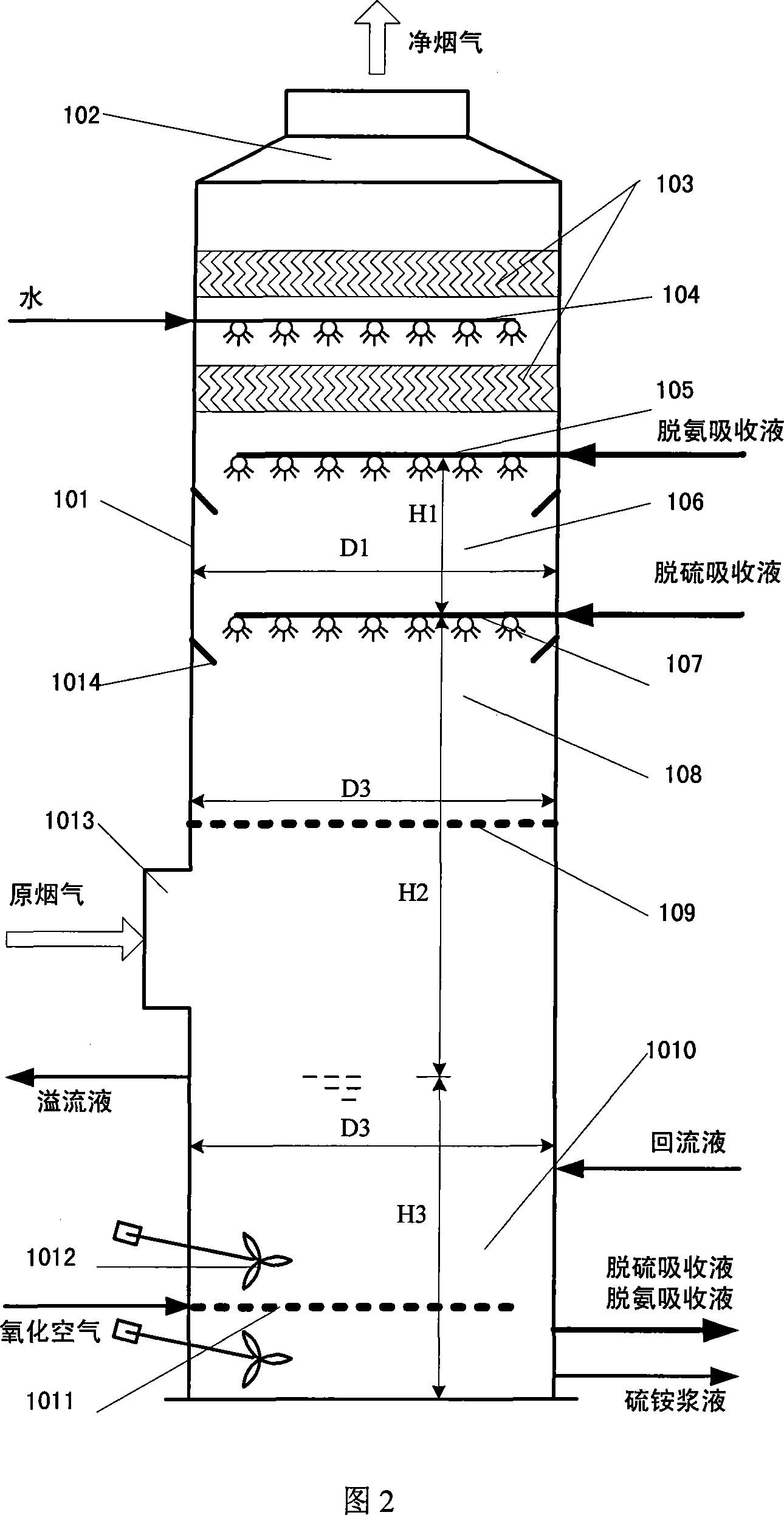

[0070] The center of the tower top of the sulfur dioxide absorption device is provided with a circular purified flue gas outlet, and a gas-liquid separation component is installed at the upper part of the tower body; a flushing water distributor connected to the water inlet is installed under the gas-liquid separation component; A deammonization circulating absorbing liquid distributor connected to the inlet of the ammonia circulating absorbing liquid is set under the deammonization absorbing liquid distributor; ...

Embodiment 2

[0082] A 300MW unit, burning coal with a sulfur content of 3.5%, with a flue gas flow rate of 1.2 million Nm 3 / hr, SO 2 The content is 9000mg / Nm 3 , the content of other pollutants in the flue gas is: dust = 220mg / Nm 3 , SO 3 =105mg / Nm 3 , HCl=35mg / Nm 3 , HF=20mg / Nm 3 , NOx=500mg / Nm 3 , the flue gas temperature is 135°C.

[0083] The raw material for sulfur dioxide absorption is liquefied ammonia.

[0084] The flue gas outlet of the sulfur dioxide absorbing device is set on the tower body close to the top of the tower, which is a rectangular mouth; the gas and liquid separation components are set on the upper part of the tower body; the flushing connected to the water inlet is set under the gas and liquid separation components Water distributor; a deammonization circulating absorption liquid distributor connected to the deammonization circulating absorption liquid inlet is arranged under the flushing water distributor; a deammonization zone is set under the deammoniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com