Polyelectrolyte / intrinsic conducting polymer composite humidity sensor and its production method

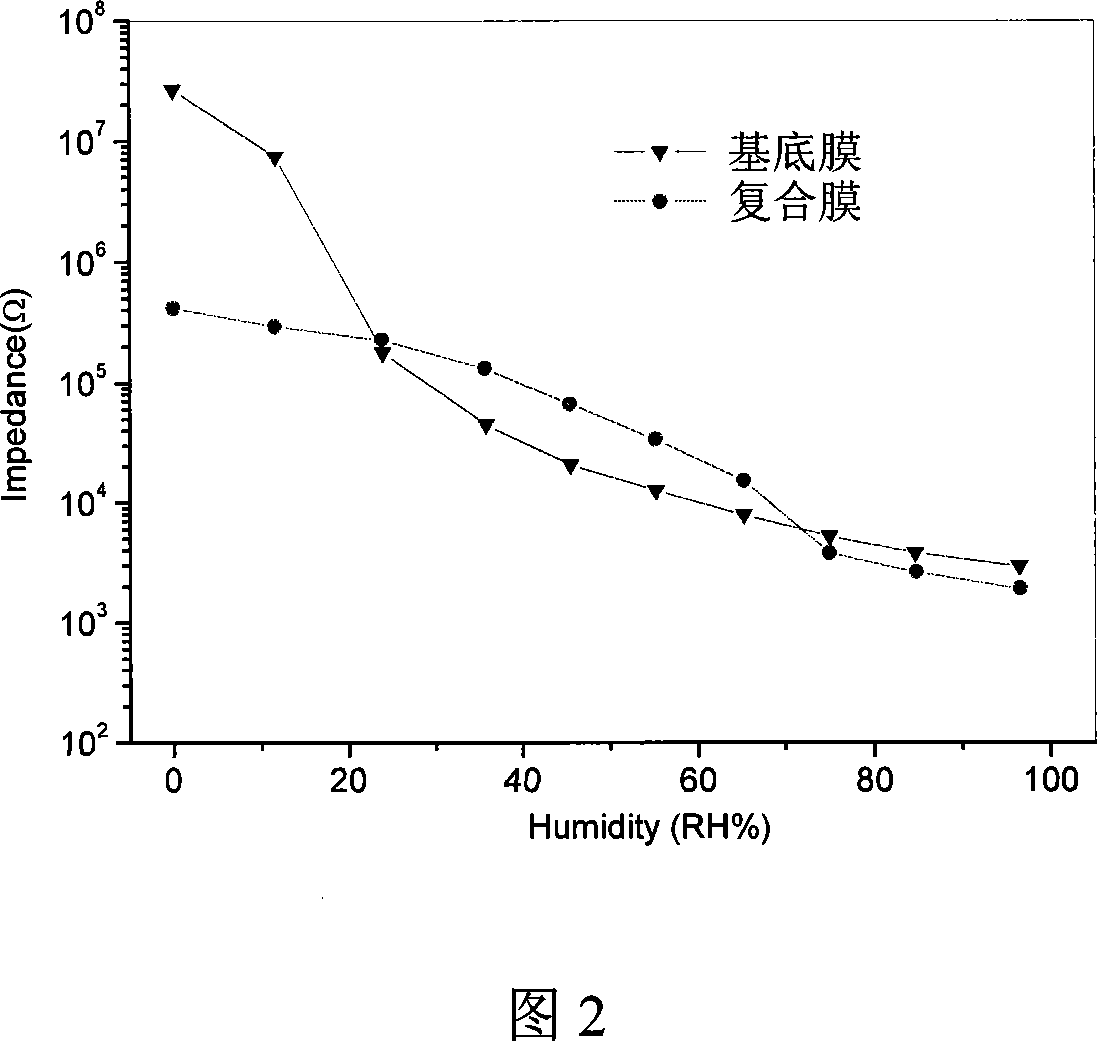

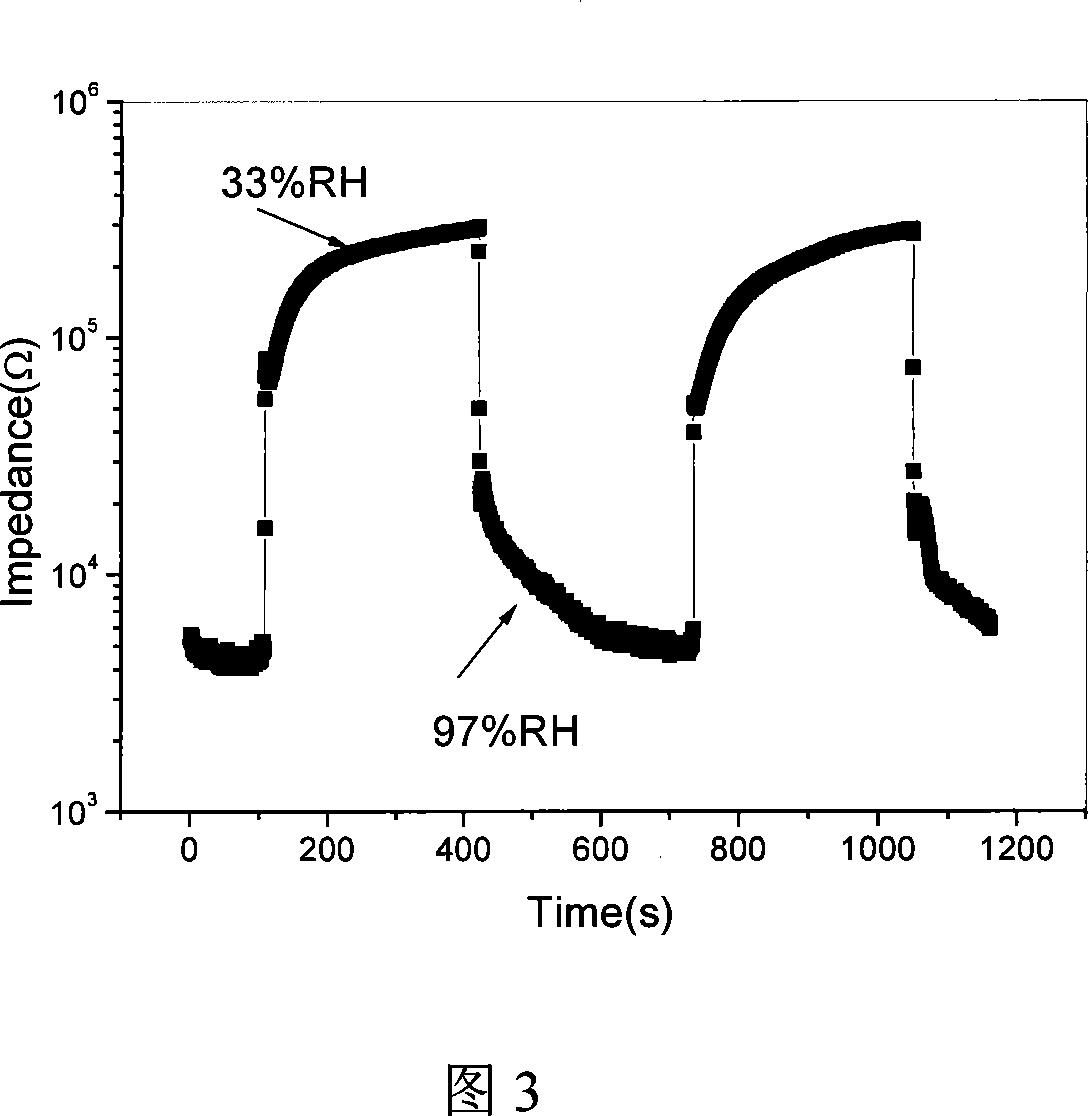

A technology of composite humidity sensor and polyelectrolyte, which is applied in the field of polyelectrolyte/intrinsically conductive polymer composite humidity sensor, can solve the problems of low ion mobility, excessive resistance value, hindering development, etc., and achieve good response linearity , improve consistency, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

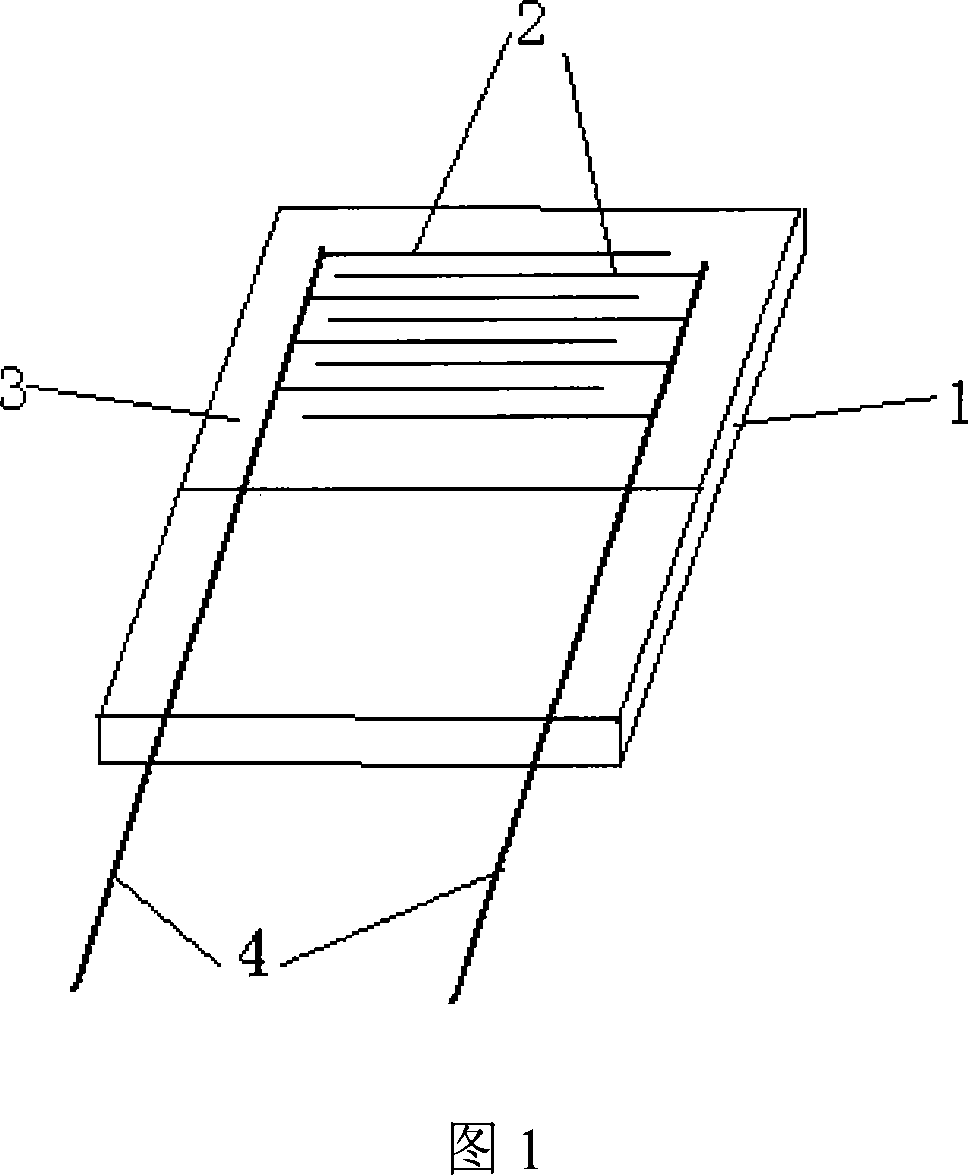

[0030] 1) Soak and clean the glass-ceramics substrate with interdigitated gold electrodes on the surface photoetched and evaporated with absolute ethanol and acetone, and dry for later use;

[0031] 2) Dissolve poly 4-vinylpyridine and 1,4-dibromobutane in N,N-dimethylformamide, the 4-vinylpyridine unit in the polymer and 1,4-dibromobutane The molar ratio of the solution is 1:0.5, prepared into a solution with a polymer concentration of 10 mg / ml, and placed at 30° C. for 4 hours to obtain a precursor solution;

[0032] 3) Use a dipping machine to immerse the glass-ceramic interdigitated gold electrode in step 1) in the precursor solution for 0.5 minutes, pull it out, cross-link and quaternize it at 80°C for 12 hours, and place it on the glass-ceramic interdigitated gold electrode A polyelectrolyte basement membrane is formed on the surface;

[0033] 4) Ammonium persulfate and 4-methylbenzenesulfonic acid were dissolved in deionized water, the mass ratio of ammonium persulfate...

Embodiment 2

[0036] 1) Electrode cleaning is the same as in Example 1;

[0037] 2) Dissolve poly 4-vinylpyridine and 1,4-dibromobutane in N,N-dimethylformamide, the 4-vinylpyridine unit in the polymer and 1,4-dibromobutane The molar ratio is 1:2, and it is prepared into a solution with a polymer concentration of 30 mg / ml, and placed at 30° C. for 12 hours to obtain a precursor solution;

[0038] 3) Use a dipping machine to immerse the glass-ceramic interdigitated gold electrode in step 1) in the precursor solution for 2 minutes, pull it out, cross-link and quaternize it at 140°C for 2 hours, and coat the glass-ceramic interdigitated gold electrode A polyelectrolyte basement membrane is formed on the surface;

[0039] 4) Ammonium persulfate and 4-methylbenzenesulfonic acid were dissolved in deionized water, the mass ratio of ammonium persulfate and 4-methylbenzenesulfonic acid was 1:3, and the concentration of ammonium persulfate was 4 mg / ml, to obtain Solution A;

[0040] 5) Use a dippi...

Embodiment 3

[0042] 1) Electrode cleaning is the same as in Example 1;

[0043] 2) Dissolve poly 4-vinylpyridine and 1,4-dibromobutane in N,N-dimethylformamide, the 4-vinylpyridine unit in the polymer and 1,4-dibromobutane The molar ratio is 1:1, prepared into a solution with a polymer concentration of 24 mg / ml, and placed at 30° C. for 12 hours to obtain an electrolyte precursor solution;

[0044] 3) Use a dipping machine to immerse the glass-ceramic interdigitated gold electrode in step 1) in the precursor solution for 1 minute, pull it out, cross-link and quaternize it at 110°C for 10 hours, and coat the glass-ceramic interdigitated gold electrode A polyelectrolyte basement membrane is formed on the surface;

[0045] 4) Dissolving ammonium persulfate and 4-methylbenzenesulfonic acid in deionized water, the mass ratio of ammonium persulfate and 4-methylbenzenesulfonic acid is 1:2, the concentration of ammonium persulfate is 1.5 mg / ml, Obtain solution A;

[0046] 5) Use a dipping machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com