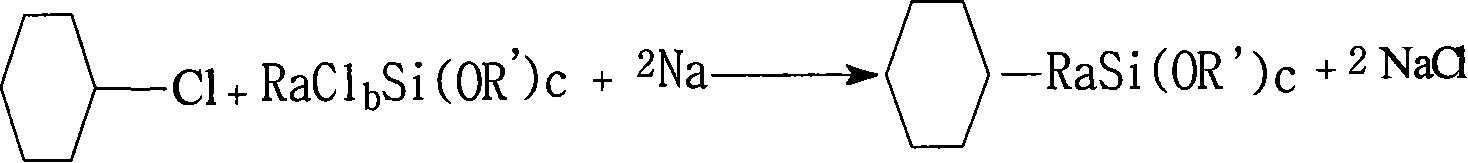

Alkyl cyclohexyl dialkoxy silane prepared by sodium condensation method

A technology of cyclohexyldialkoxysilane and sodium condensation method, which is applied in the field of synthesis of alkylcyclohexyldialkoxysilane by sodium condensation method, can solve the problems of useless production, expensive organic lithium, poor stability, etc., and achieve reduction The effect of production cost, shortened reaction cycle, and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

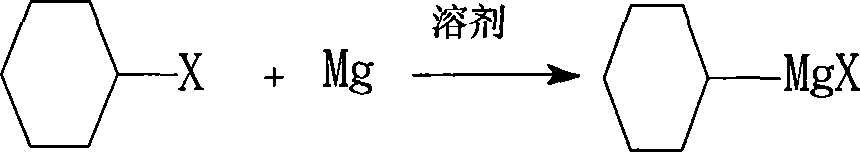

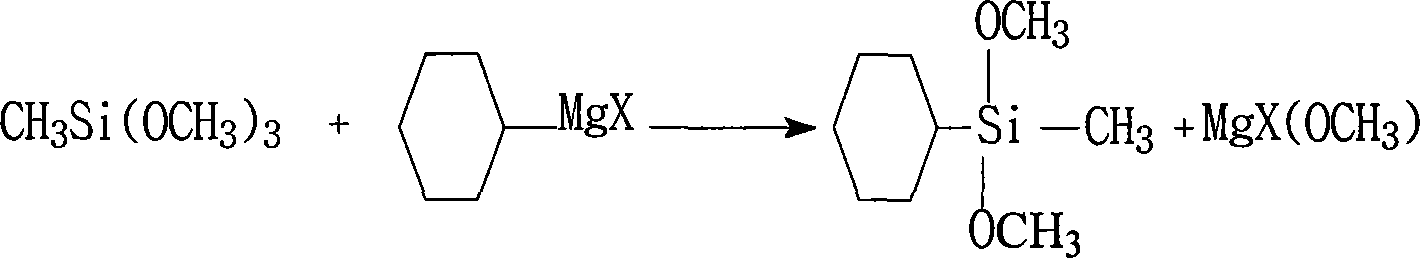

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Add 30g of toluene into a three-necked flask, then add 11.5g of metallic sodium, heat and stir, break the sodium into sodium sand above 100°C, then slowly drop in 30g of chlorocyclohexane and 68g of methyl Chlorodimethoxysilane [CH 3 SiCl(OCH 3 ) 2 ] and 20g of n-heptane mixed solution, the reaction temperature is controlled at 100 ~ 104 ℃. The mixed solution was dropped within 35 minutes, kept warm for 0.5 hours, and the product was evaporated under reduced pressure. According to gas chromatography analysis, the yield of methylcyclohexyldimethoxysilane was 51.9% (mass fraction).

Embodiment 2

[0044] Example 2: Add 40 g of toluene and 6 g of sodium metal into a three-necked flask, raise the temperature to 100 ° C, and break the sodium metal into sodium sand under stirring, and mix 15 g of chlorocyclohexane and CH at 106 ° C 3 SiCl(OCH 3 ) 2 34g of the mixed solution was slowly dripped into the three-necked flask, and the dripping was completed within 40min, kept at reflux temperature for 1.5h, and then the product was evaporated under reduced pressure, and analyzed by gas chromatography to obtain methylcyclohexyldimethoxysilane. Rate 49.9%.

Embodiment 3

[0045] Embodiment three: 23.5g (content 98%) sodium metal and 100g CH 3 Si(OCH 3 ) 3 Add it to a three-necked flask, heat and stir, break metal sodium into sodium sand, keep it above 100°C, drop 59g of chlorocyclohexane and 84g of methylchlorodimethoxysilane at the same time, within about 1h After dripping all the raw materials, keep the temperature at 102-106°C for 2 hours, distill the crude product under reduced pressure, the remaining residue is off-white, a total of 58g, the crude product is analyzed by gas chromatography, and the yield of methylcyclohexyldimethoxysilane is 61 % (mass fraction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com