Method for depositing tin oxide base thin film on mobile hot glass surface

A surface deposition, tin oxide-based technology, applied in the field of tin oxide-based functional thin films, can solve the problems of not mentioning reactive gas filtration, not mentioning the suppression of optical interference color, not involving, etc., to achieve good chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

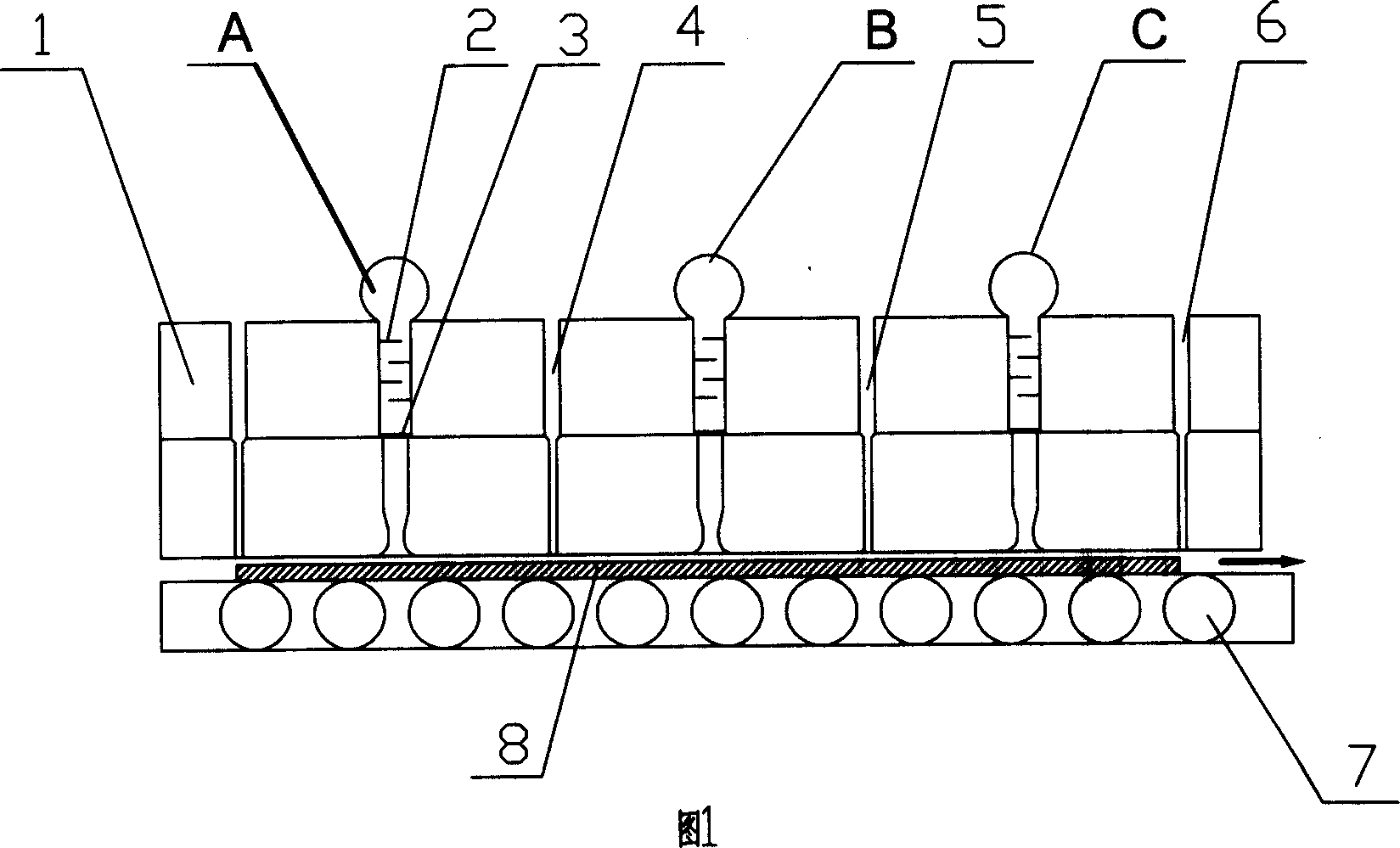

[0026] As shown in Figure 1, the chemical vapor phase reactor 1 is arranged above the roller table 7, and the glass 8 moves to the right in the gap between the roller table 7 and the chemical vapor phase reactor 1, and the chemical vapor phase reactor 1 is provided with three gas Inlets A, B, and C have a gas outlet 4, 5, and 6 on their right sides respectively, and each gas inlet is provided with a damping plate 2 and a filter plate 3, and the damping plate is fixed in front of the filter plate, and the filter plate can be obtained from chemical One side of the gas phase reactor is withdrawn for replacement. The main function of setting the damping plate and the filter plate in the air intake channel is to consume the energy of the gas in the flow process, so that the gas can be pre-mixed well, and the purpose of uniform air flow mixing can be achieved. At the same time, the filter plate can also filter out part of the dust generated due to the pre-reaction.

[0027] Control...

Embodiment 2

[0029] Control the moving line speed of the glass substrate at about 120m / hr, the temperature at 600±5°C, use nitrogen as the carrier gas, and pass the gaseous tetraethyl orthosilicate, monobutyltin trichloride, water vapor and other mixtures into the chemical The first inlet of the gas phase reactor, the mole percentages of the components in the gaseous mixture are: tetraethyl orthosilicate 0.030, monobutyl tin trichloride 0.022, water vapor 0.016, and the rest is nitrogen; Carrier gas, the gaseous monobutyl tin trichloride, ethyl acetate, water vapor, oxygen and other mixtures are passed into the second inlet, and the mole percentages of each component in the gaseous mixture are: monobutyl trichloride Tin 0.026, ethyl acetate 0.010, water vapor 0.019, oxygen 0.034, and the rest is nitrogen; nitrogen is used as the carrier gas, and gaseous trifluoroacetic acid is passed into the third inlet, wherein the molar percentage of trifluoroacetic acid is 0.023. The obtained tin oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com