Gravure rubber wheel directly transfer printing pattern metallic plate

A metal plate and template technology, applied in the direction of metal layered products, metal material coating process, superimposed layer plating, etc. The effect of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

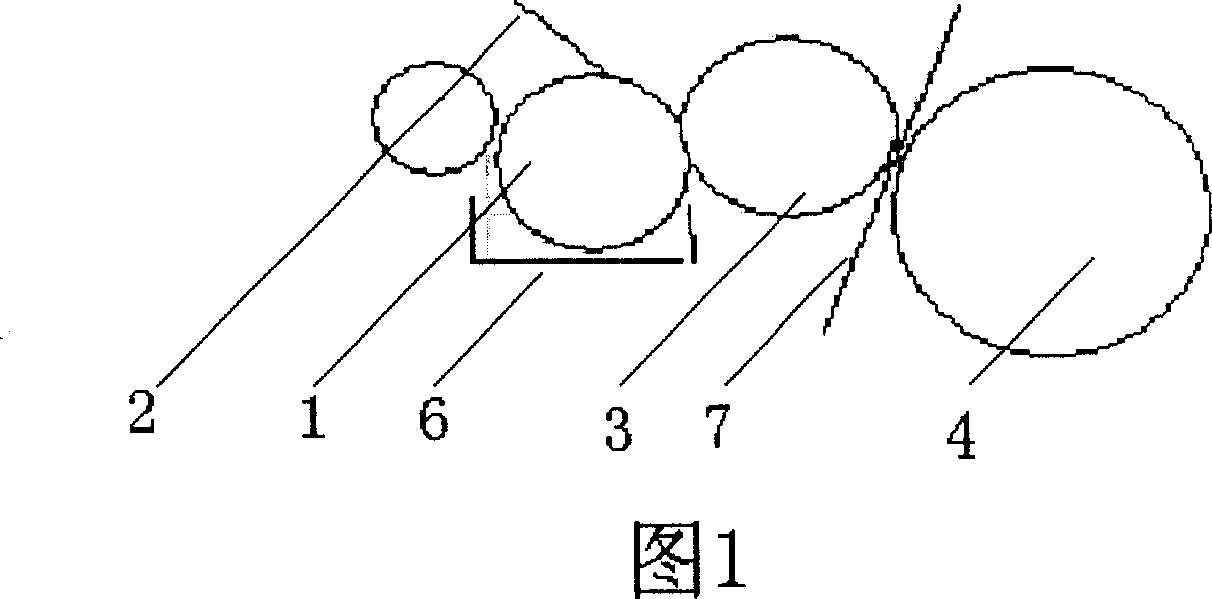

[0042]In this embodiment, the printing process is as follows, a gravure roll 1, the gravure roll 1 is immersed in the printing ink storage tank 6 to continuously coat the ink, the gravure roll 1 after the ink is dipped Use the scraper 2 to scrape off excess ink, and the ink pattern on the gravure roller 1 is transferred to the surface of the printing rubber roller 3, and the printing rubber roller 3 prints the ink pattern on its surface on the steel plate 7, and the other side of the steel plate is provided with a Support roller 4.

Embodiment 2

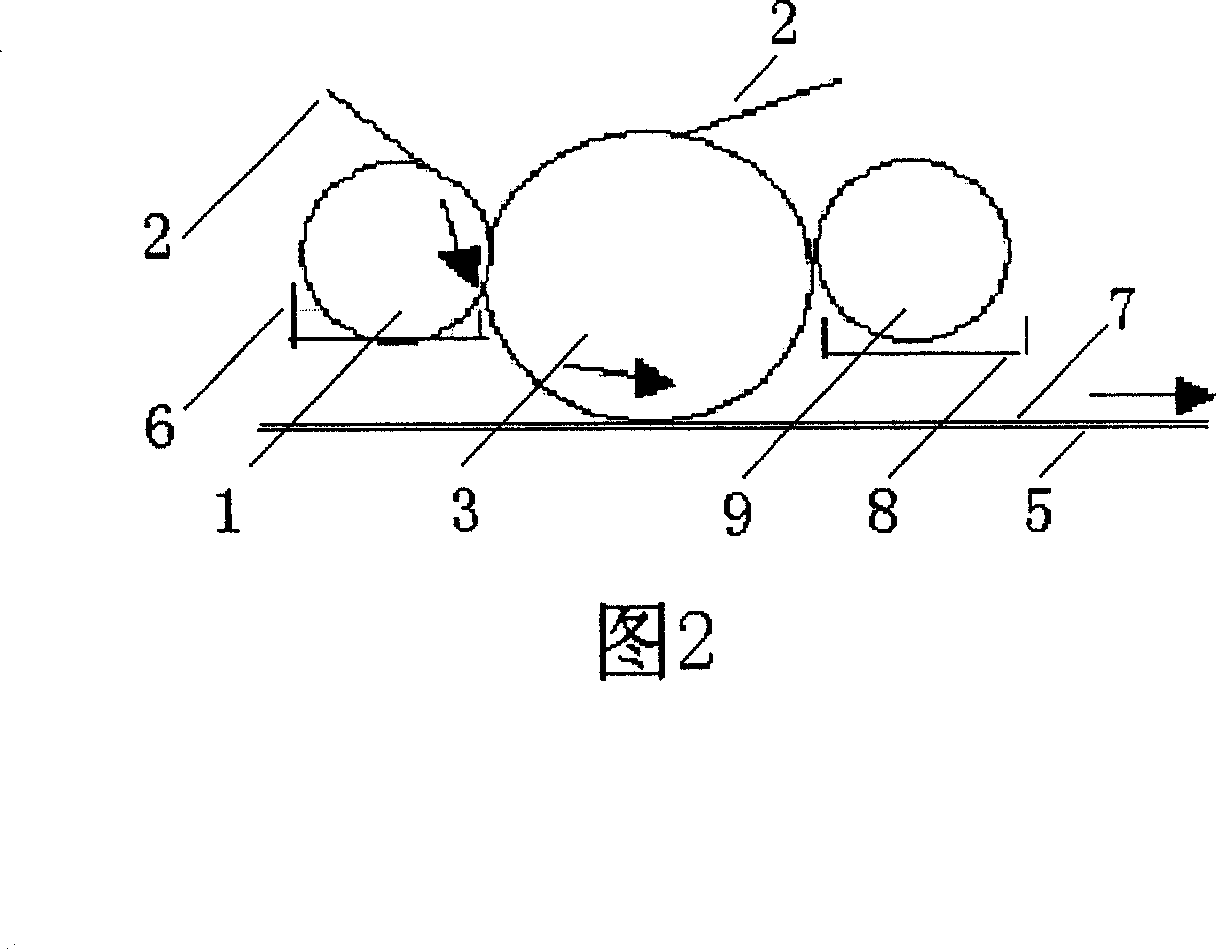

[0044] In this embodiment, the printing process is as follows, a gravure roll 1, the gravure roll 1 is immersed in the printing ink storage tank 6 to continuously coat the ink, the gravure roll 1 after the ink is dipped Use the scraper 2 to scrape off the excess ink, the ink pattern on the gravure roller 1 is transferred to the surface of the printing rubber roller 3, and the printing rubber roller 3 prints the ink pattern on its surface on the steel plate 7, and the support of the steel plate 7 is on the plane On the support transmission belt 5, on the other side of the printing rubber roller 3, a cleaning roller 9 is arranged, and the cleaning roller 9 is immersed in the washing tank 8 and is continuously cleaned. Another doctor blade 2 is arranged on the printing rubber roller 3 .

[0045] In the steel plate printing process of the present invention, if the ink printing lines are not clear, a cleaning roller can be added at the position of the printing rubber roller.

[00...

Embodiment 3

[0051] After the resin and ink are mixed in the following ratio, that is, resin Medium:black ink=3:1, the viscosity of their mixture under the 5# cup is 18 seconds.

[0052] 20

40

60

80

100

17.22

13.48

12

10.8

10.25

[0053] Through research, the direction of the researchers of the present invention, the preferred solvent ratio, adopts the ratio of common type solvent: slow-drying solvent=1:1.

[0054] Under the condition that described ink of the present invention has been proportioned, preferred printing conditions are as follows:

[0055] (1) Drying temperature: 180 degrees;

[0056] (2) SP value (surface tension) above 13;

[0057] (3) The continuous coating and printing process speed for steel coils can reach 15-40 m / min, and the printing process speed for single steel plates can reach 5-20 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com