Double-micropore zeolites and method of making thereof

A microporous zeolite and zeolite technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problem that the repeatability of synthesizing double microporous molecular sieves is difficult to control, and the amount of additional aluminum source and alkali is difficult to grasp. and other problems, to achieve good thermal and hydrothermal stability, strong acidity, and the effect of improving Si/Al ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

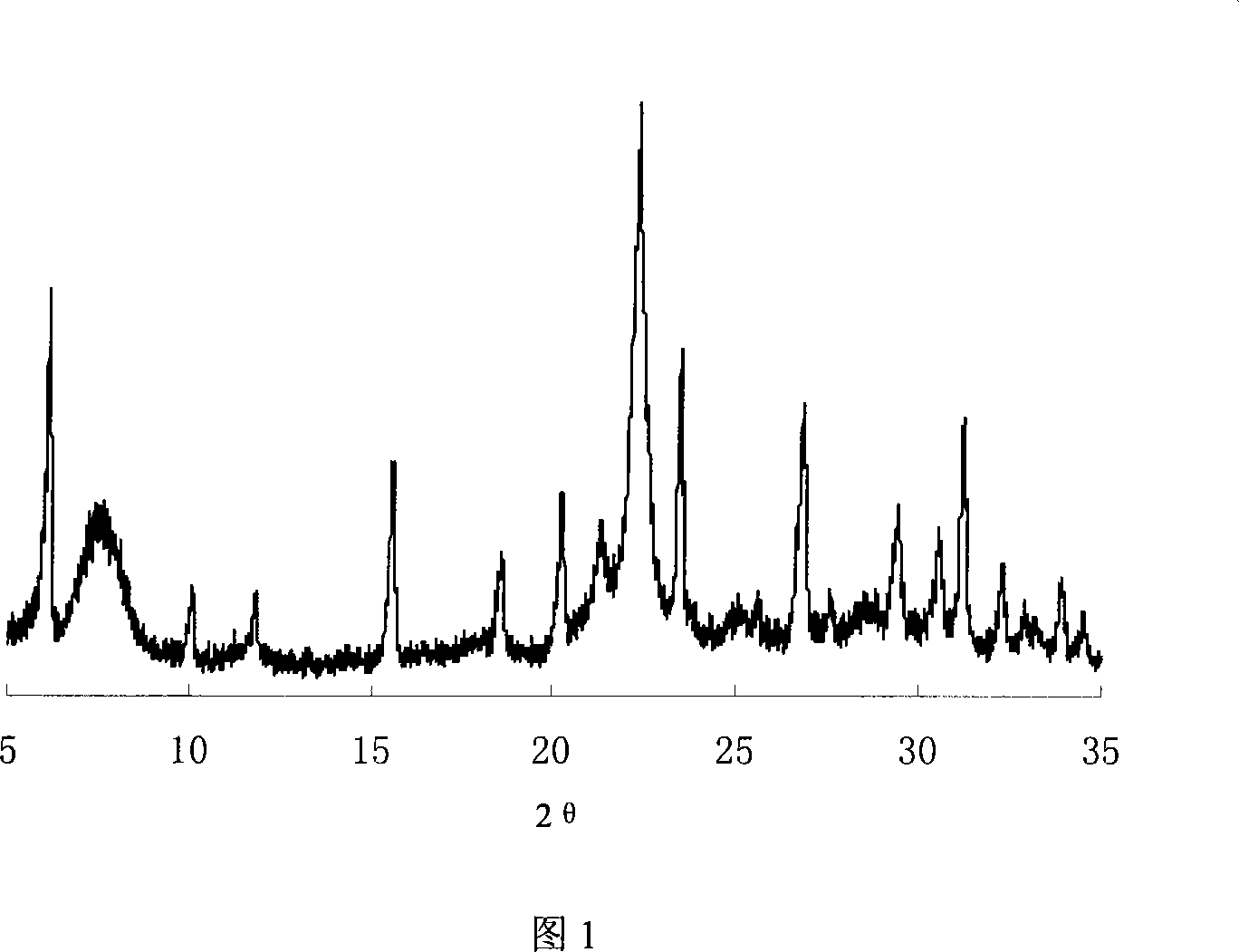

Image

Examples

Embodiment approach 1

[0018] Step 1: Mix 17.4g TEABr (tetraethylammonium bromide), 6ml concentrated ammonia water, 2.26g sodium metaaluminate, 0.5g NaOH, 31ml silica sol, and 34ml distilled water to form a uniform white jelly, and put it into 100ml stainless steel In the reaction kettle, crystallize at 140°C for 10 days and take it out for use. The molar ratio of the original material of Beta zeolite is: 2.2Na 2 O: 20SiO 2 :Al 2 o 3 : 4.6 (TEA) 2 O: 4.6 (NH 4 ) 2 O: 440H 2 O.

[0019] The second step: Add 2.35g sodium metaaluminate, 1.31g sodium hydroxide, and 2.5mlY directing agent to the solid-liquid mixture containing Beta zeolite synthesized above, and the total molar ratio of materials is: 2.62Na 2 O:Al 2 o 3 : 9.7SiO2 2 : 2.32 (TEA) 2 O: 2.32 (NH 4 ) 2 O: 215H 2 O. Then mix and stir evenly, put it into a 100ml stainless steel reaction kettle, crystallize at 85°C for 24h, take it out, then cool it with tap water at room temperature, then wash it with distilled water until neutra...

Embodiment approach 2

[0021]Step 1: Mix 17.4g TEABr (tetraethylammonium bromide), 6ml concentrated ammonia water, 2.26g sodium metaaluminate, 0.5g NaOH, 31ml silica sol, and 34ml distilled water to form a uniform white jelly, and put it into 100ml stainless steel In the reaction kettle, crystallize at 145°C for 8 days and take it out for use. The molar ratio of the original material of Beta zeolite is: 2.2Na 2 O: 20SiO 2 :Al 2 o 3 : 4.6 (TEA) 2 O: 4.6 (NH 4 ) 2 O: 440H 2 O.

[0022] The second step: Add 2.97g sodium metaaluminate, 1.31g sodium hydroxide, and 3.5mlY directing agent to the solid-liquid mixture containing Beta zeolite synthesized above, and the total material molar ratio is: 2.47Na 2 O:Al 2 o 3 : 8.55SiO2 2 : 2.04 (TEA) 2 O: 2.04 (NH 4 ) 2 O: 190H 2 O. Mix and stir to form a uniform white substance, put it into a 100ml stainless steel reaction kettle, crystallize at 90°C for 24 hours, take it out, then cool it with tap water at room temperature, then wash it with distil...

Embodiment approach 3

[0024] Step 1: Mix 17.4g TEABr (tetraethylammonium bromide), 6ml concentrated ammonia water, 2.26g sodium metaaluminate, 0.5g NaOH, 31ml silica sol, and 34ml distilled water to form a uniform white jelly, and put it into 100ml stainless steel In the reaction kettle, crystallize at 135°C for 13 days and take it out for use. The molar ratio of the original material of Beta zeolite is: 2.2Na 2 O: 20SiO 2 :Al 2 o 3 : 4.6 (TEA) 2 O: 4.6 (NH 4 ) 2 O: 440H 2 O.

[0025] The second step: Add 3.15g of sodium metaaluminate, 1.07g of sodium hydroxide, and 3.5ml of Y-directing agent to the solid-liquid mixture containing Beta zeolite synthesized above. The total molar ratio of materials is: 2.30Na 2 O:Al 2 o 3 : 8.27SiO2 2 : 1.98 (TEA) 2 O: 1.98 (NH 4 ) 2 O: 184H 2 O. Mix and stir to form a uniform white substance, put it into a 100ml stainless steel reaction kettle, crystallize at 90°C for 24 hours, take it out, then cool it with tap water at room temperature, then wash it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com