Physical simulating method and device during continuous-casting billet coagulation tissue growth process

A technology of solidification structure and growth process, applied in the field of metal crystalline phase heat treatment processing, can solve the problems of difficult research work, high cost, lack of directness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

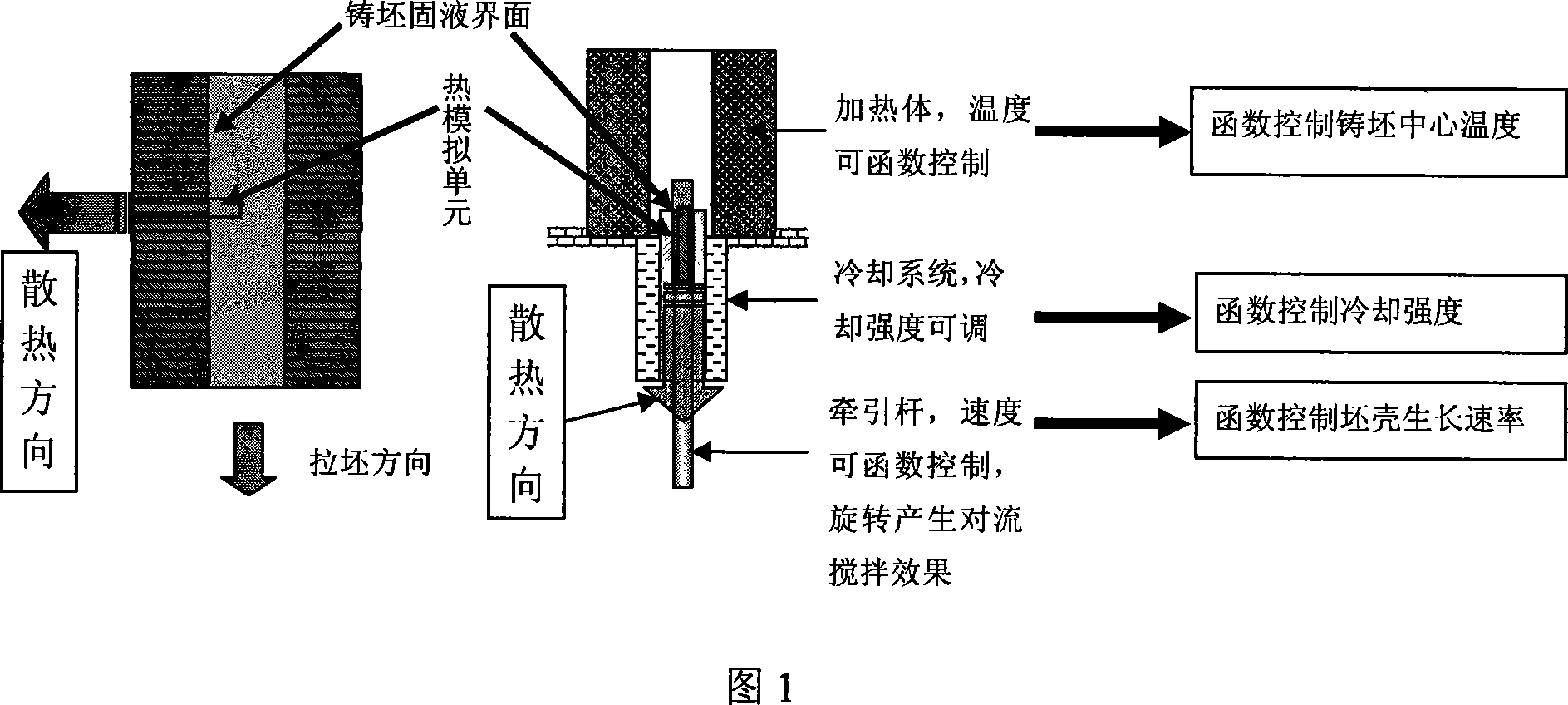

[0028] Referring to Fig. 1, Fig. 1 is the schematic diagram of the method for simulating the solidification structure growth process in the continuous casting process of the present invention. In this method, three function control programs are mainly designed and set as the research means of this method. They are:

[0029] (1) Functional heating control program for the center temperature of the slab thermal simulation unit;

[0030] (2) A function control program that can adjust the cooling intensity of the cooling system;

[0031] (3) A function control program that can control the moving speed or stretching rate of the draw bar or tie rod; that is, the function control program that can control the solidification growth rate of the slab shell.

[0032] The growth process of the solidification structure in the simulated continuous casting process is mainly studied through the cooperation of the above three function control programs.

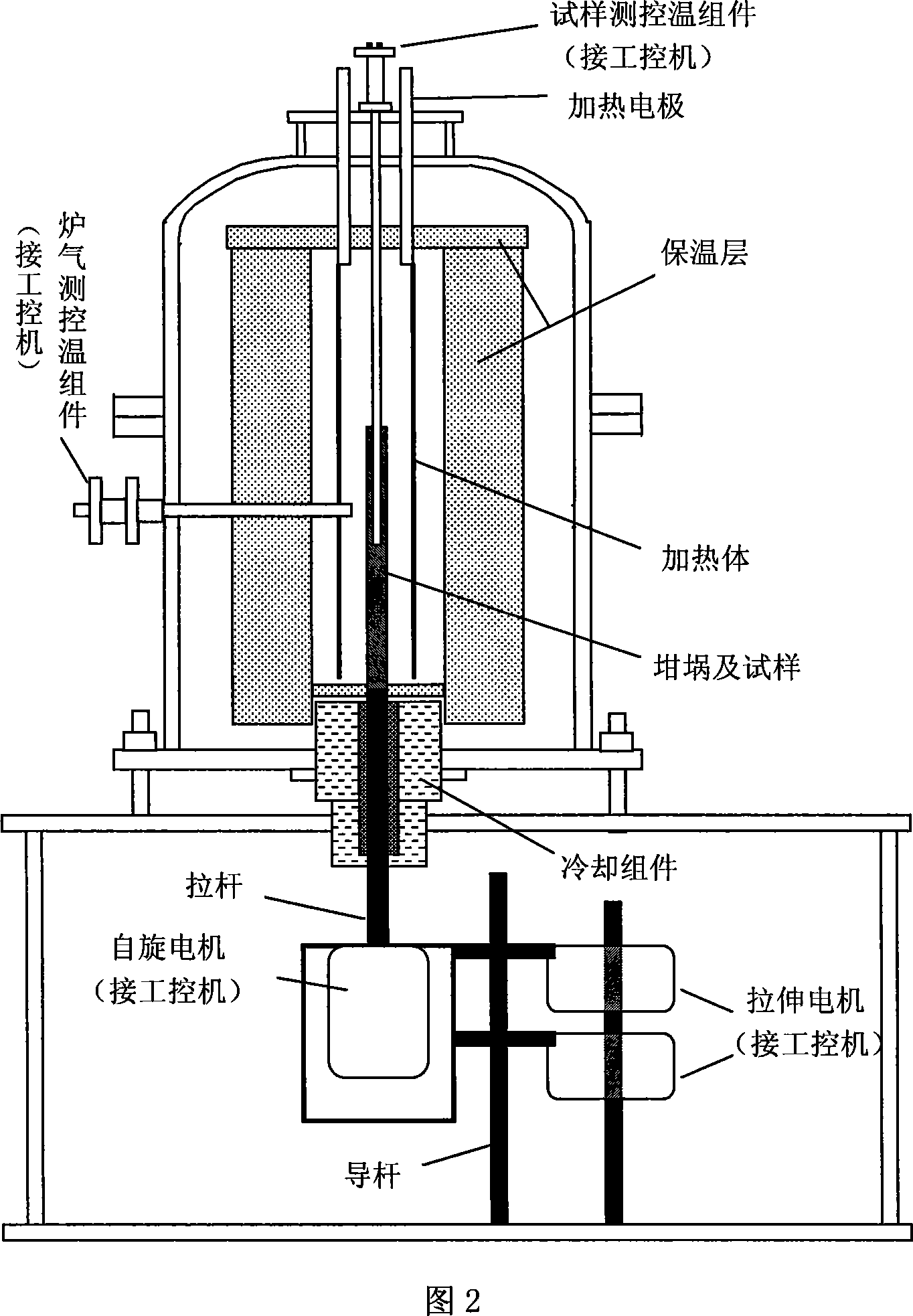

[0033] Referring to Fig. 2, Fig. 2 is a...

experiment example 1

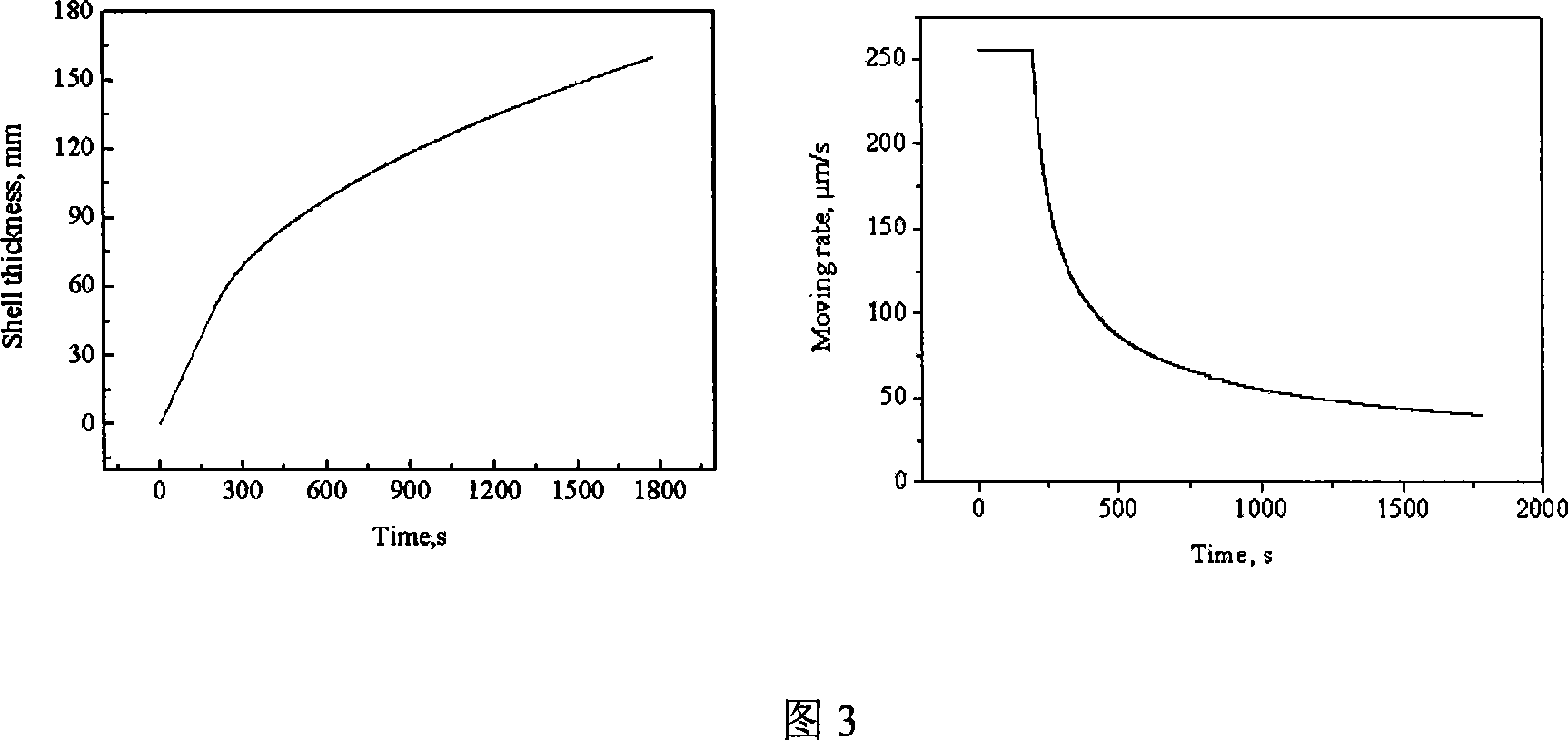

[0042] Using 1Cr18Ni9Ti austenitic stainless steel as the base material, a test rod with a diameter of 7 mm was made, placed in a high-purity corundum crucible, heated to 1350 ° C, and kept for 20 min. The stretching curve is set according to the growth and stretching of the slab shell during the slab continuous casting process, and the displacement time equation of the stretching curve is:

[0043] d s = K · t ,

[0044] The velocity-time equation is:

[0045]

[0046] The coagulation coefficient K is 25mm / min 1 / 2 . When the casting speed is set to 1.2m / min, the effective length at the outlet of the crystallizer is 800mm. The heating temperature in the homogeneous temperature zone of continuous directional solidification is set at 1530° C. at the core temperature of the slab in the continuous casting process. During the simulation process, the program control int...

experiment example 2

[0049] In order to verify whether the device can meet the cooling rate of the slab liquid core, a certain cooling rate is set in different temperature ranges when the temperature is high, and the follow-up of the cooling situation is investigated.

[0050] time(s)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com