Method for liquefying liquid-solid medium barrier plasma coal under atmospheric normal pressure

A plasma and dielectric barrier technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of harsh reaction conditions and high cost, and achieve the effects of mild conditions, easy control and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

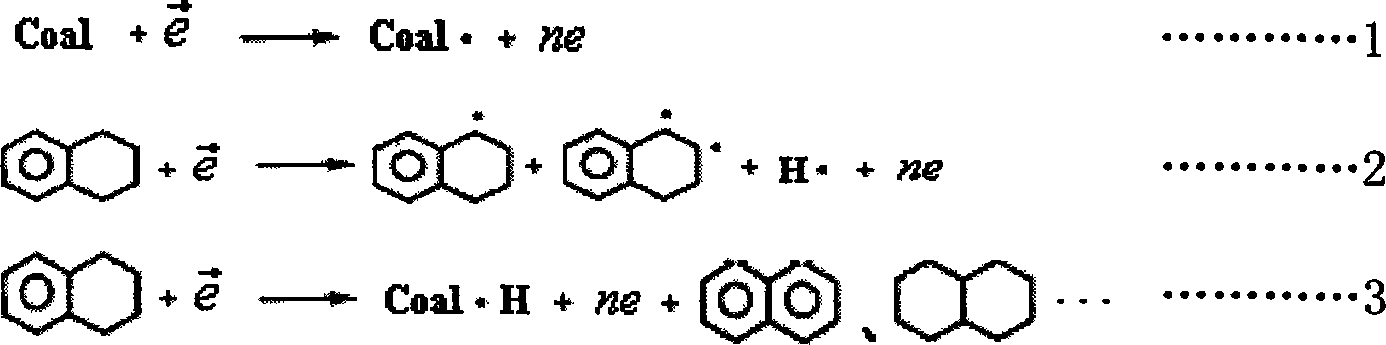

Method used

Image

Examples

Embodiment Construction

[0017] Atmospheric atmospheric pressure liquid-solid dielectric barrier (DBD) plasma coal direct liquefaction method, the present invention selects the material of the dielectric barrier (DBD) plasma reactor to be quartz materials, because the dielectric constant of quartz glass is high, the expansion coefficient is low, High temperature resistance, chemical stability, and electrical insulation are relatively good. It is a good dielectric and has a stabilizing and enhancing effect on the electric field in the reactor. The reactor adopts a line-and-tube structure, and the reaction temperature for the reaction to produce coal liquefaction products is controlled at 150°C to 180°C. A strong local electric field can be formed near the electrode line; the formed non-uniform electric field is strong inside and weak outside, which effectively avoids the phenomenon of gas breakdown; it can discharge in the entire reactor, and the plasma is spread throughout the entire reactor. The quartz m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com