Treatment of high-concentration oily waste water

A treatment process and high-concentration technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as high cost, unsatisfactory treatment effect, and difficulty in waste sludge treatment. Achieve the effect of low processing cost, good application prospect and promotion value, and ability to inhibit miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

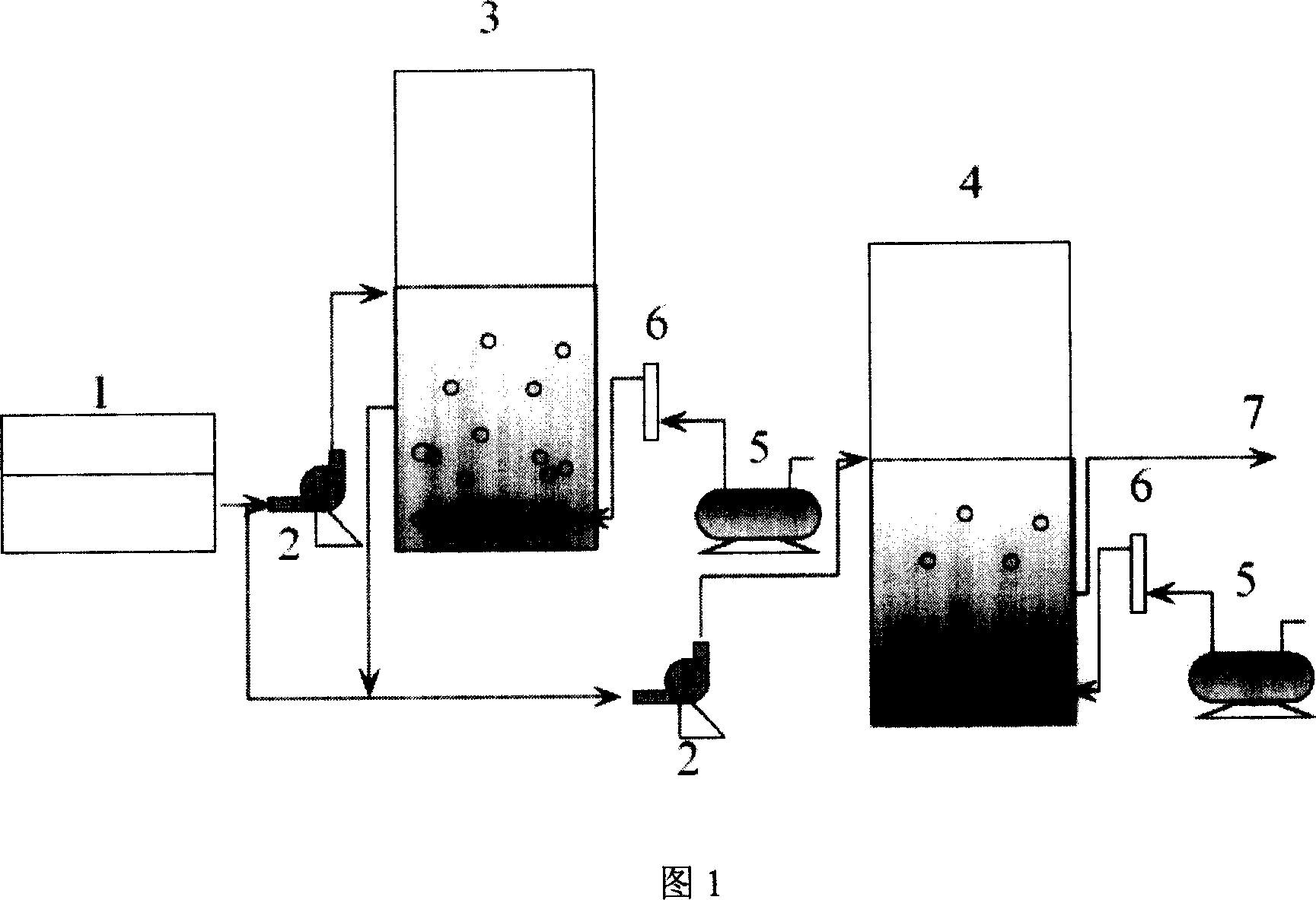

[0020] On the device shown in Figure 1, the salad oil wastewater produced by an alkali refining process in a salad oil refinery is treated.

[0021] Firstly, the yeast strains purchased from the "General Microbiology Center of China Microbiological Culture Collection Management Committee" and the preservation numbers are CGMCC No2. The primary SBR reactor 3 (reactor volume 22.4L, using mesopore aeration) is used for the treatment of the above-mentioned salad oil processing wastewater (that is, high-concentration organic wastewater). The treatment conditions are 12 hours of aeration, 2 hours of static In the operation mode of sinking and draining, under the control of the gas flow meter 6, air is blown into the first-stage SBR reactor 3 through the air compressor 5, the dissolved oxygen is controlled below 2.0 mg / L, and the pH is 6. The yeast The concentration of bacteria in wastewater is 12g / L, and the BOD load of treatment is 1.5 kg of BOD per kg of yeast per day, and the COD...

Embodiment 2

[0026] On the device shown in Figure 1, the high-concentration oily wastewater discharged from a certain salad oil refinery using the alkali refining process is treated.

[0027] The first-level SBR reactor 3 (reactor volume 22.4L, adopts mesopore aeration) accesses the yeast strains with preservation numbers: CGMCC No 2.2156, 2.2158, 2.2165, 2.1207, and 2.1764 to treat the above-mentioned high-concentration oily wastewater processing. The treatment conditions are 10 hours of aeration, 2 hours of static settling and draining operation mode. Under the control of the gas flow meter 6, air is blown into the primary SBR reactor 3 through the air compressor 5, and the dissolved oxygen is controlled at 2.0 mg. Below / L, pH at 6, the concentration of the yeast in the wastewater is 10g / L, and the BOD load of the treatment is 1.0 kg of BOD per kg of yeast per day, the COD of the influent Cr The concentration is 15000mg / L; after mixing the effluent treated by yeast with part of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com