Method for producing kallidin proenzyme raw-material medicine

A technology for kallikrein and bulk drug, which is applied in the field of preparing high-purity biological bulk drug, and can solve the problems of high price, low purity, loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

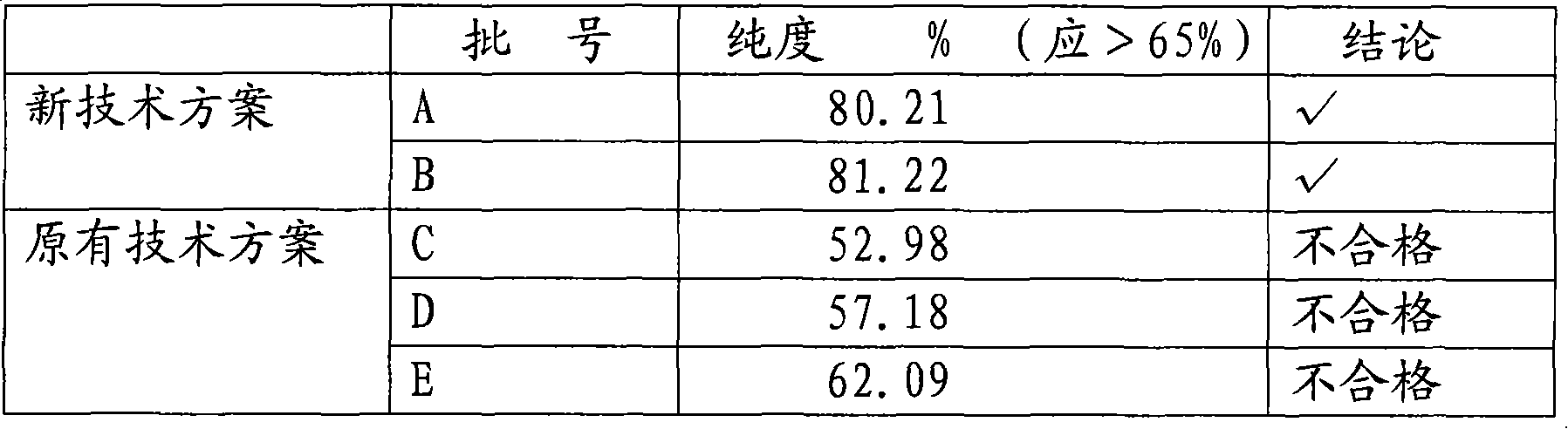

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare 0.15mol / L NH 4 AC buffer and 0.5mol / L NH 4 AC buffer solution was adjusted to pH 6.0 with acetic acid and ammonia water, and the conductivity value was measured.

[0028] 2. Chromatography

[0029] 2.1 Equilibrium for column packing: install the ionic column filler QAE-Sepharose Fast Flow in a ¢40cm, volume 50L chromatographic column, and use 0.15mol / L NH at pH 6.0 4 The AC buffer solution is balanced until the pH value of the incoming and outgoing solution is the same, and the conductivity value is the same, and then the balance is completed.

[0030] 2.2 Sample injection: adjust the pH value of the kininogenase intermediate to be similar to that of the equilibrium solution (6.1-6.2), and the conductance value is slightly lower than that of the equilibrium solution (slightly lower by 0.2-0.3×10 4 μs / cm), according to the maximum exchange capacity of 20 million units per liter of filler, calculate the sample volume. Load the sample solution onto the column. ...

Embodiment 2

[0041] Prepare 0.5mol / L NH 4 AC buffer and 0.1mol / L NH 4 AC buffer solution was adjusted to pH 6.0 with acetic acid and ammonia water, and the conductivity value was measured.

[0042] 2. Chromatography

[0043] 2.1 Equilibrium for column packing: install the ionic column filler QAE-Sepharose Fast Flow in a ¢40cm, volume 50L chromatographic column, and use 0.15mol / L NH at pH 6.04 The AC buffer solution is balanced until the pH value of the incoming and outgoing solution is the same, and the conductivity value is the same, and then the balance is completed.

[0044] 2.2 Sample injection: adjust the pH value of the kininogenase intermediate to be similar to that of the equilibrium solution (6.1-6.2), and the conductance value is slightly lower than that of the equilibrium solution (slightly lower by 0.2-0.3×10 4 μs / cm), according to the maximum exchange capacity of 20 million units per liter of filler, calculate the sample volume. Load the sample solution onto the column.

...

Embodiment 3

[0055] Prepare 0.35mol / L NH 4 AC buffer and 0.3mol / L NH 4 AC buffer solution was adjusted to pH 6.0 with acetic acid and ammonia water, and the conductivity value was measured.

[0056] 2. Chromatography

[0057] 2.1 Equilibrium for column packing: install the ionic column filler QAE-Sepharose Fast Flow in a ¢40cm, volume 50L chromatographic column, and use 0.15mol / L NH at pH 6.0 4 The AC buffer solution is balanced until the pH value of the incoming and outgoing solution is the same, and the conductivity value is the same, and then the balance is completed.

[0058] 2.2 Sample injection: adjust the pH value of the kininogenase intermediate to be similar to that of the equilibrium solution (6.1-6.2), and the conductance value is slightly lower than that of the equilibrium solution (slightly lower by 0.2-0.3×10 4 μs / cm), according to the maximum exchange capacity of 20 million units per liter of filler, calculate the sample volume. Load the sample solution onto the column. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com