Method and apparatus for processing sole and heel surface skin lines

A technology for processing equipment and processing methods, which is applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve the problems of complex process methods, low production efficiency, and high production costs, and achieve simple production processes, high production efficiency, and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Processing method of the present invention comprises the steps:

[0013] 1) Molded plastic heels and soles;

[0014] 2) Pretreatment, spraying primer on the surface of the formed heel and sole;

[0015] 3) Topcoating, coating the pretreated heel and sole through the equipment for surface treatment of the heel and sole.

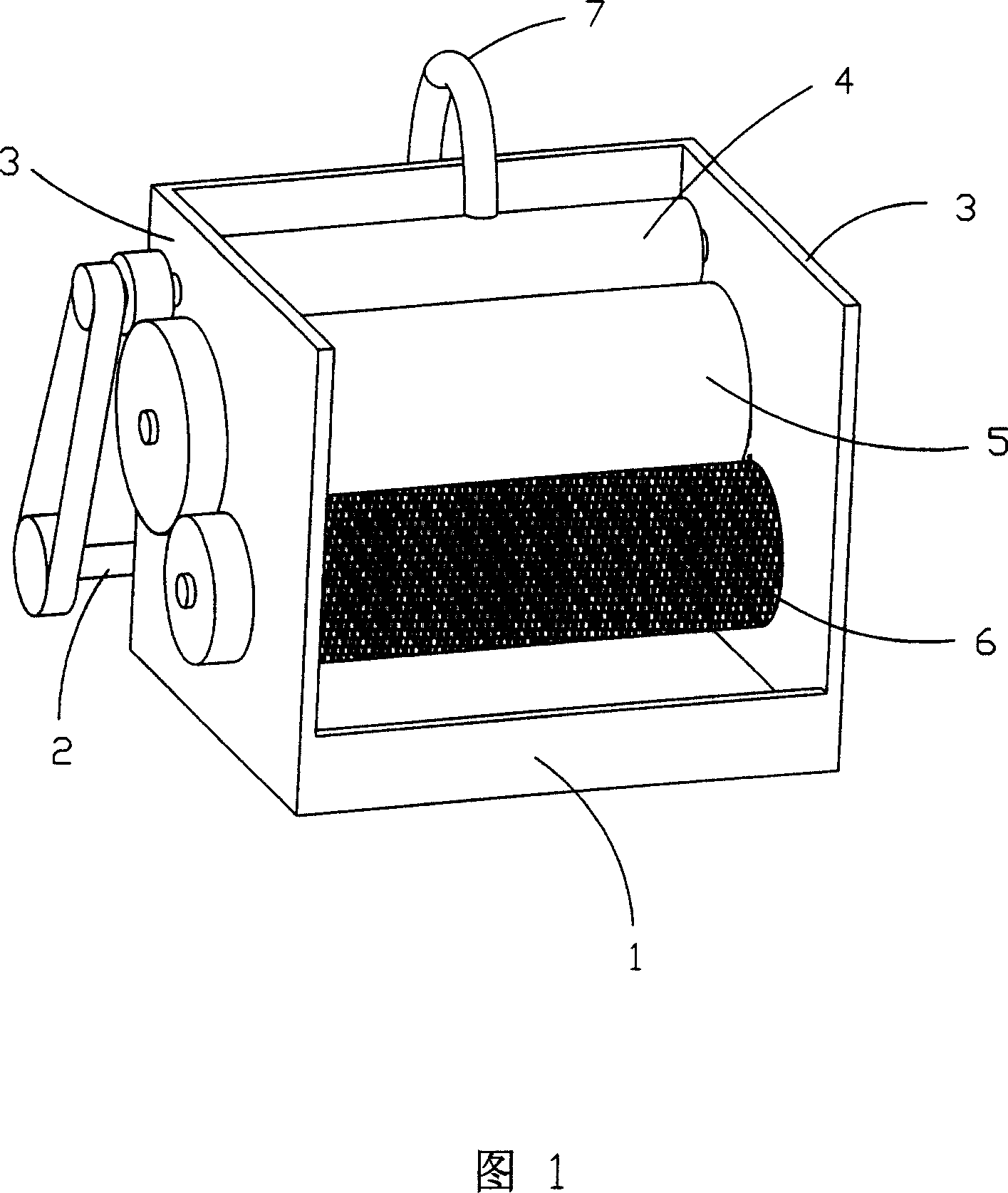

[0016] As shown in Fig. 1, the used equipment of the processing method of the present invention comprises a tank body 1 and a motor 2, side walls 3 are formed on both sides of the tank body 1, and a drive wheel 4, a PU wheel 5, and a printing wheel 6 are arranged successively above the tank body 1, The driving wheel 4, the PU wheel 5 and the printing wheel 6 are in contact with each other and are arranged in a slope. The above three wheels are fixed on the two side walls 3 of the tank body 1. One end of the driving wheel 4 is connected to the output of the motor 2 through the transmission belt. Shaft connection, two ends of driving wheel 4, PU wheel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com