Housing

A shell and decent technology, applied in the direction of transformer/inductor casing, inductor, transformer/inductor coil/winding/connection, etc., can solve the problems of high cost and failure rate, and achieve the reduction of manufacturing cost and failure rate , The effect of reducing the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

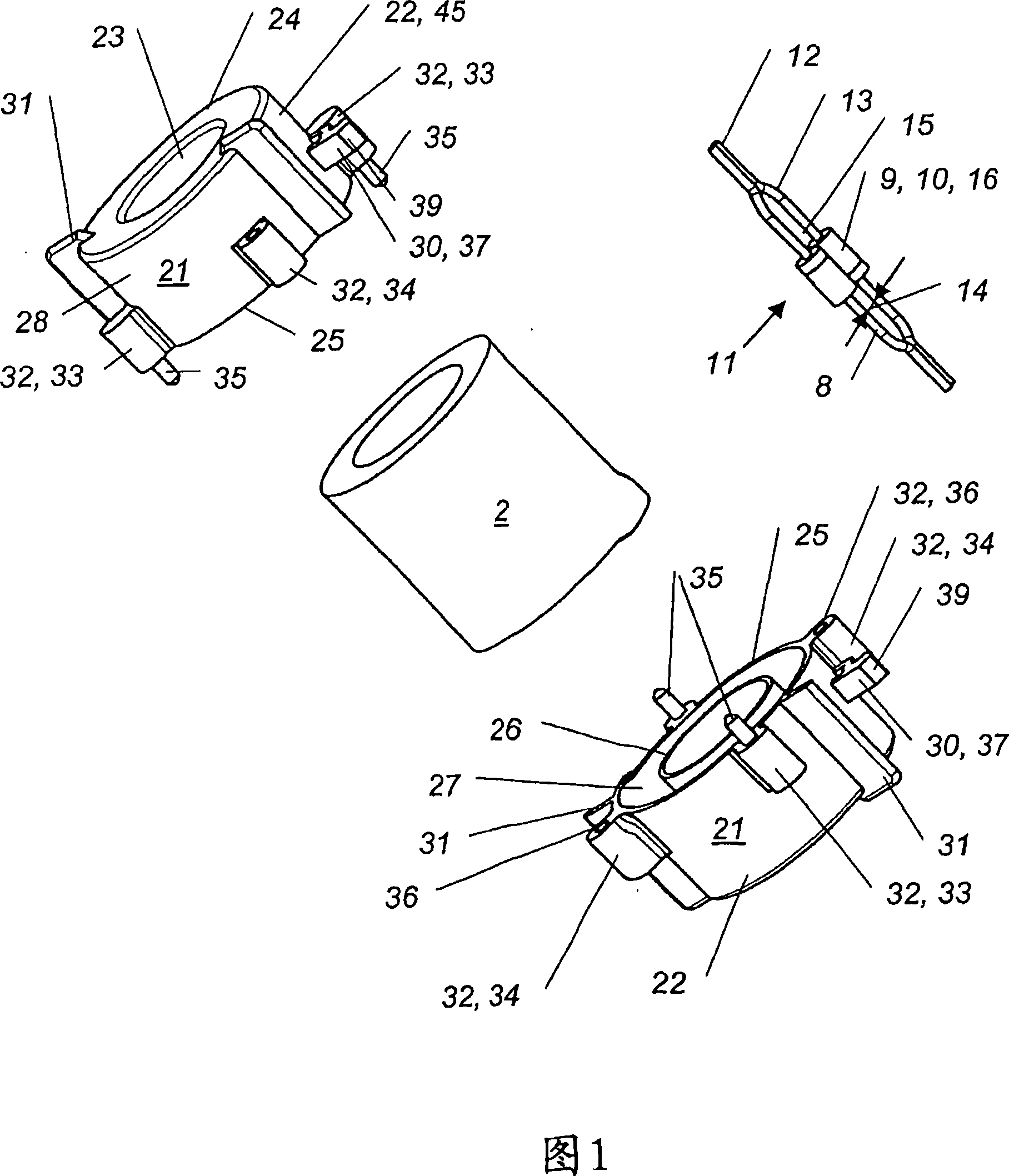

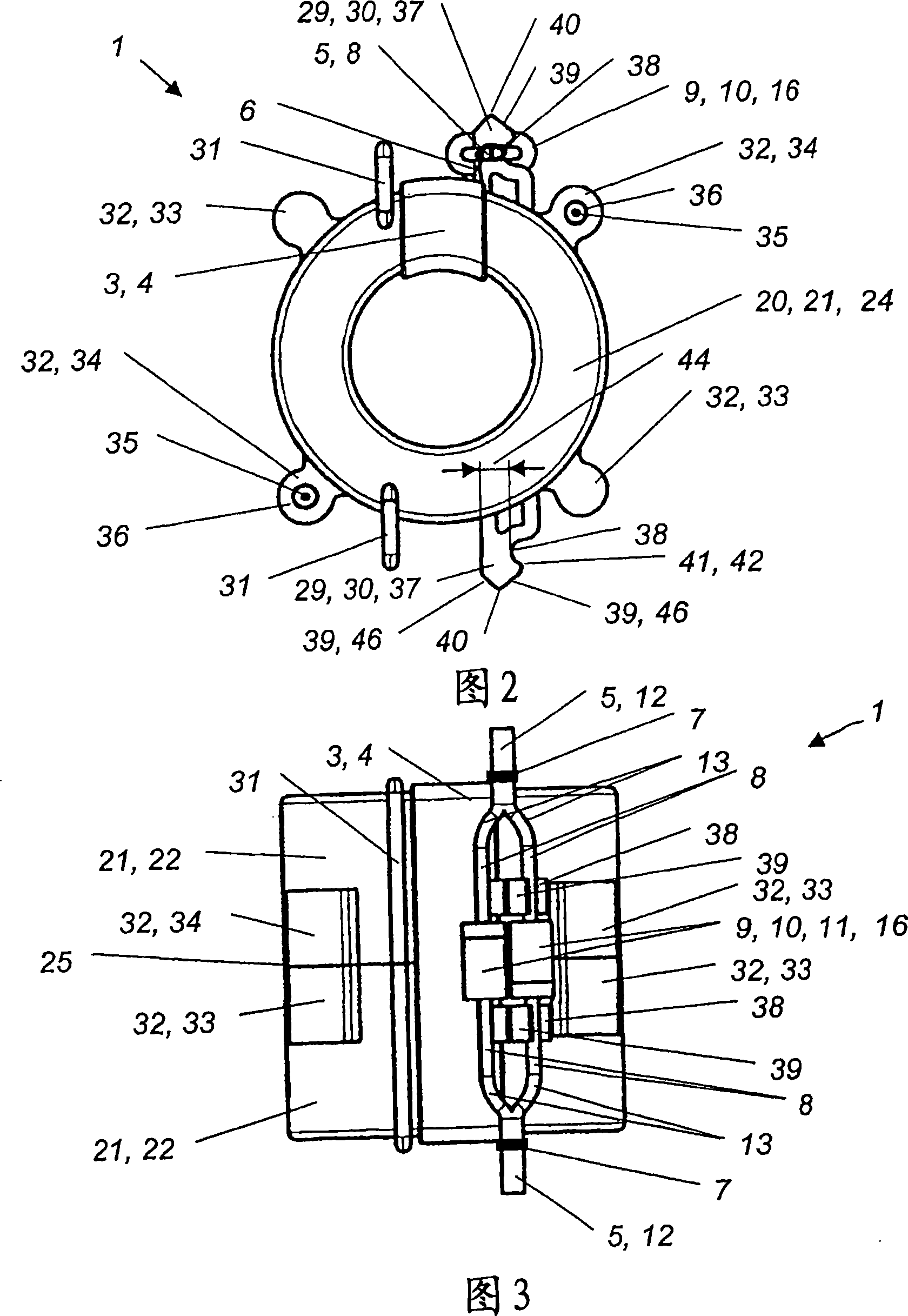

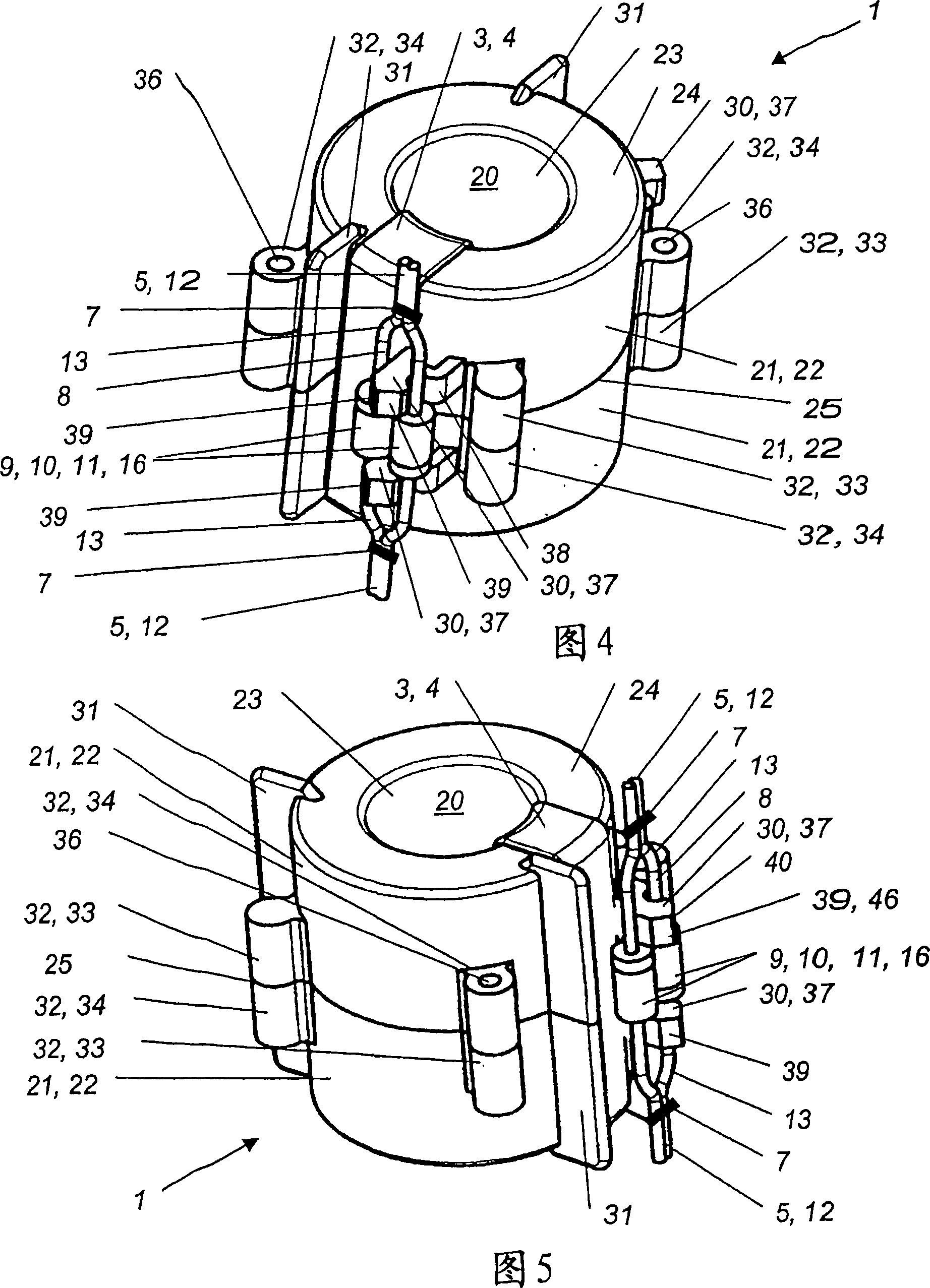

[0050] Clamping section 29 or partial clamping section 30 is arranged in a first preferred embodiment in such a way that at least one axially or radially wired electronic component 10 is substantially parallel to the housing surface, which is formed essentially as cylindrical housing surface 22 45 settings.

[0051] The clamping part 30 is preferably formed as a toothed extension 37 which has a receptacle 38 . The tooth-shaped extension 37 has a substantially rectangular cross section and protrudes from or is perpendicular to the outer cylindrical shell surface 22 , wherein the specific position depends on the outer dimensions of the electronic components 9 , 10 to be accommodated. In the preferred embodiment shown in FIGS. 1 to 5 , the partial clamping portion 30 is arranged such that the distance between it and the outer cylindrical shell edge 25 is at least greater than the shell of the electronic component 9 , 10 to be accommodated. half the body length.

[0052] Part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com