Lithium cell anode active substance, anode dressing and its preparing method

A positive active material and lithium battery technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of complex process, unstable product performance, high cost, etc., and achieve high platform capacity, enhanced conductivity, and uniform grinding high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

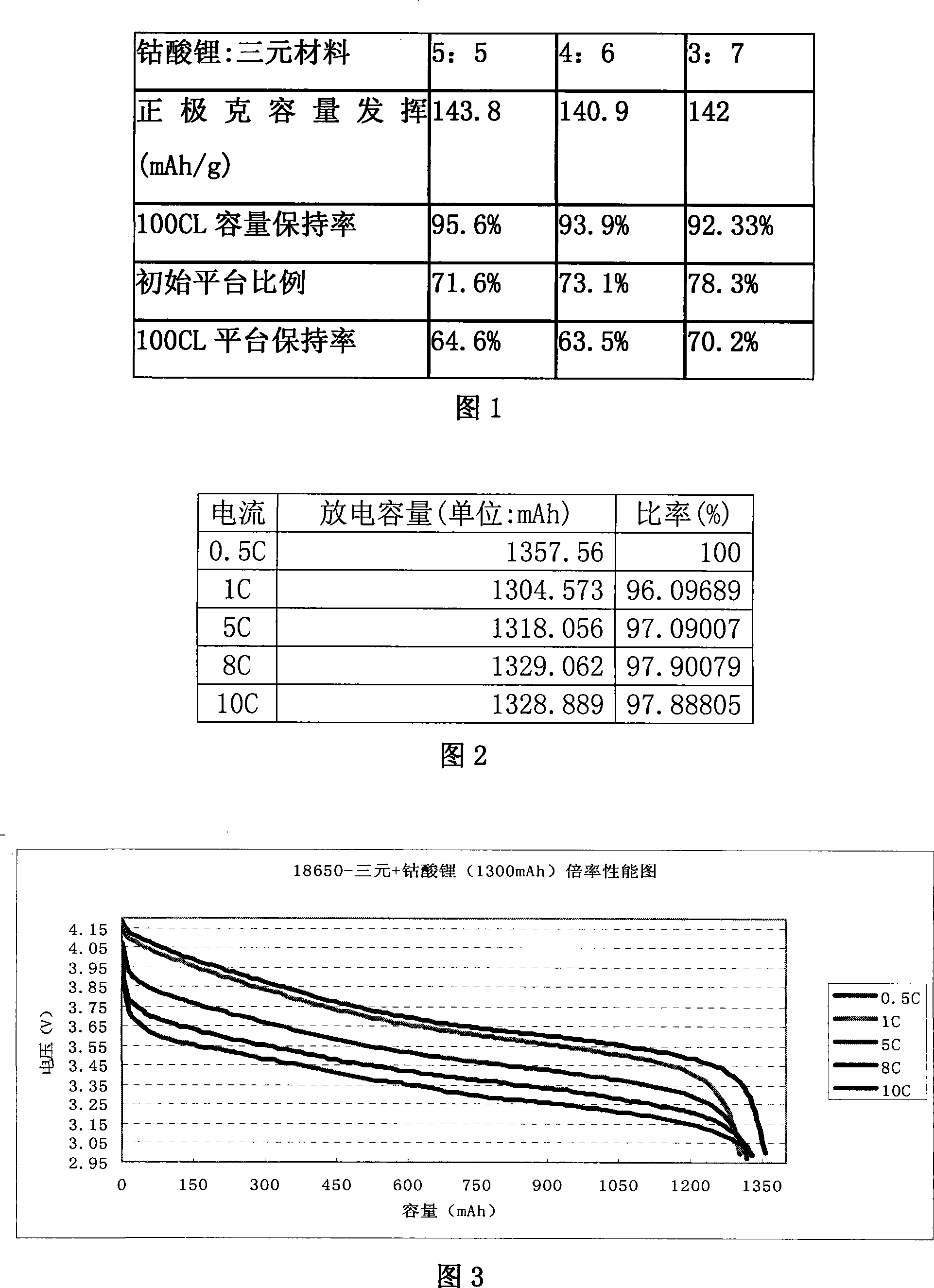

[0040] With the component ratio of ternary material: lithium cobalt oxide with a specific gravity of 5:5, ball mill according to the following steps:

[0041] 1) Add the ternary material, lithium cobaltate and graphite conductive agent into the ball milling tank, and perform ball milling at a speed of 1000-1500r / min, and the milling time is 4 hours. The diameters of the zirconium balls used for ball milling are 3mm, 6.5mm, 10mm, 15mm, and 20mm, respectively, and are placed in the ball mill jar according to the number ratio of 2:3:3:4:4.

[0042] 2) After the first step is completed, let it stand still for 30 minutes, add carbon black conductive agent into the ball mill jar, and then ball mill it at a speed of 1000r / min for 2 hours. Let stand for 1 hour.

[0043] Chemical mixing process:

[0044] 1) Add the colloids continuously and slowly to the mixed materials, and complete the feeding within half an hour, then thicken the mixture for 2 hours. After thickening, the speed of...

Embodiment 2

[0048] With the ternary material: Lithium Cobalt Oxide proportion ratio of 6:4, follow the steps below for ball milling:

[0049] 1): Add the ternary material, lithium cobaltate and graphite conductive agent into the ball milling tank, and conduct ball milling at a speed of 1000-1500r / min, and the milling time is 4 hours. The diameters of the zirconium balls used for ball milling are 3mm, 6.5mm, 10mm, 15mm, and 20mm, respectively, and are placed in the ball mill jar according to the number ratio of 2:3:3:4:4.

[0050] 2): After the first step is completed, let it stand still for 30 minutes, add carbon black conductive agent into the ball mill jar, and then ball mill it at a speed of 1000r / min for 2 hours. Let stand for 1 hour.

[0051] Chemical mixing process:

[0052] 1): Add the mixed materials slowly and continuously to the colloid, and complete the feeding within half an hour, and then stir for 2 hours. After the thick stirring, the speed of the mixer is 3600r / min.

[005...

Embodiment 3

[0056] With the ternary material: lithium cobaltate proportion ratio of 7:3, follow the steps below for ball milling:

[0057] 1) Add the ternary material, lithium cobaltate and graphite conductive agent into the ball milling tank, and perform ball milling at a speed of 1000-1500r / min, and the milling time is 4 hours. The diameters of the zirconium balls used for ball milling are 3mm, 6.5mm, 10mm, 15mm, and 20mm, respectively, and are placed in the ball mill jar according to the number ratio of 2:3:3:4:4.

[0058] 2) After the first step is completed, let it stand still for 30 minutes, add carbon black conductive agent into the ball mill jar, and then ball mill it at a speed of 1000r / min for 2 hours. Let stand for 1 hour.

[0059] Chemical mixing process:

[0060] 1) Add the colloids continuously and slowly to the mixed materials, and complete the feeding within half an hour, then thicken the mixture for 2 hours. After thickening, the speed of the mixer is 3600r / min.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com