Method for purifying tungsten hexafluoride

A technology of tungsten hexafluoride and purification method, which is applied in the direction of tungsten halide, etc., can solve the problems affecting the performance of tungsten hexafluoride, large difference in melting and boiling points, and difficulty in separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described in more detail through specific embodiments below. In addition to the embodiments mentioned in the present invention, there can also be multiple implementations, which are not limited by the embodiments of the present invention, such as changing the size of the device, etc. .

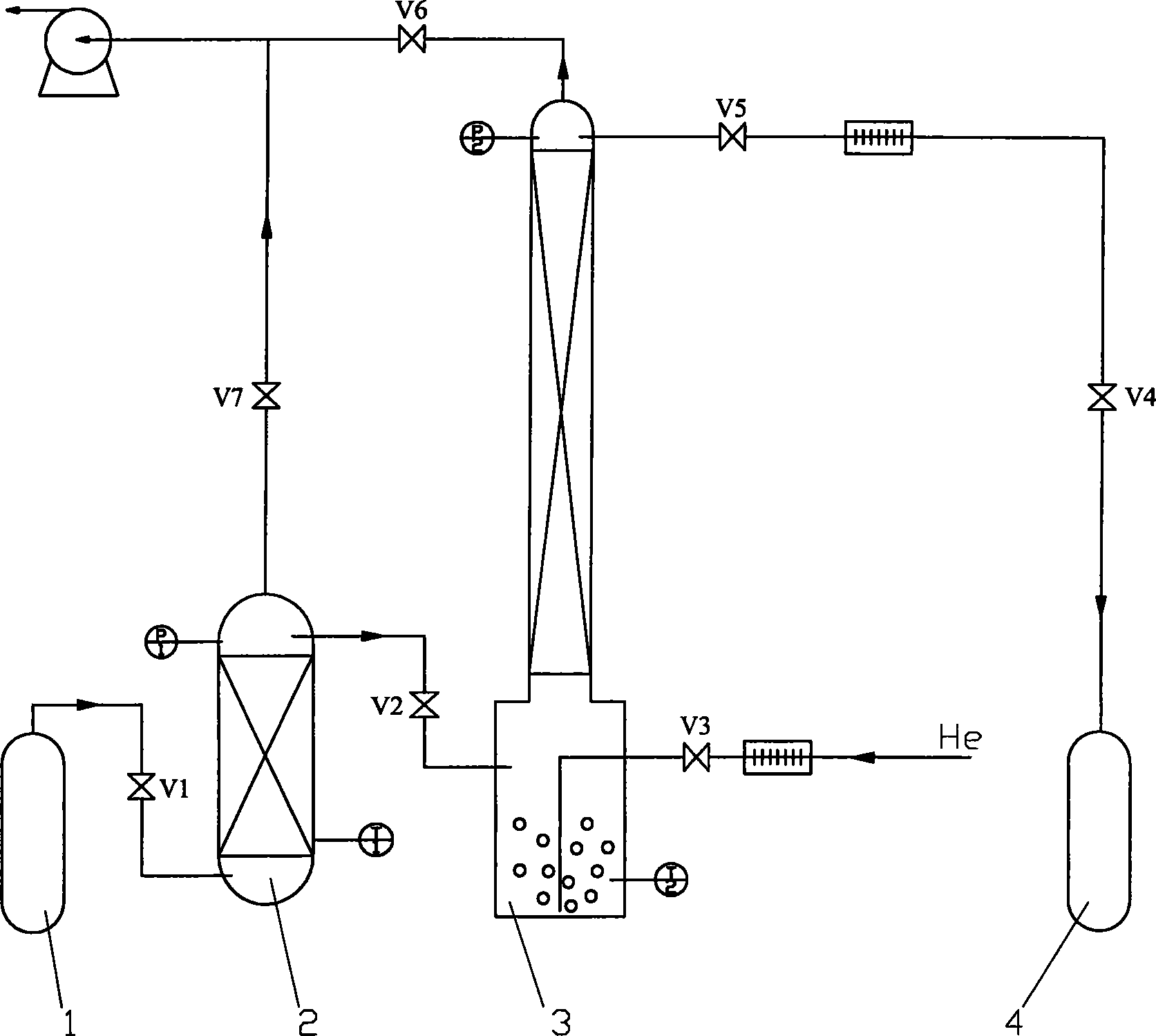

[0021] In an adsorption tower 2 with a diameter of 100mm and a height of 500mm made of Monel material, the filling diameter is 20mm, the spherical sodium fluoride particles with a porosity of 0.4, and the filling height is 450mm. Activation at 500°C to 600°C for 6h to 12h. The rectification column 3 is made of stainless steel. The diameter of the tower kettle is 100mm, and the height is 500mm. The diameter of the rectification column is 50mm, and the height is 2000mm. Stainless steel pipes are used to connect crude product storage tanks, adsorption towers, rectification towers and refined storage tanks to form WF 6 Gas purification system. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com