Magnetic head assembly positioning structure

A magnetic head assembly and positioning structure technology, applied in the direction of record carrier structural parts, support head, driving/moving recording head, etc., can solve the problems of hard disk volume increase, large installation space, and not conforming to the development trend of light and compact hard disk, etc. Achieve the effect of reducing the volume, reducing the installation space and stabilizing the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

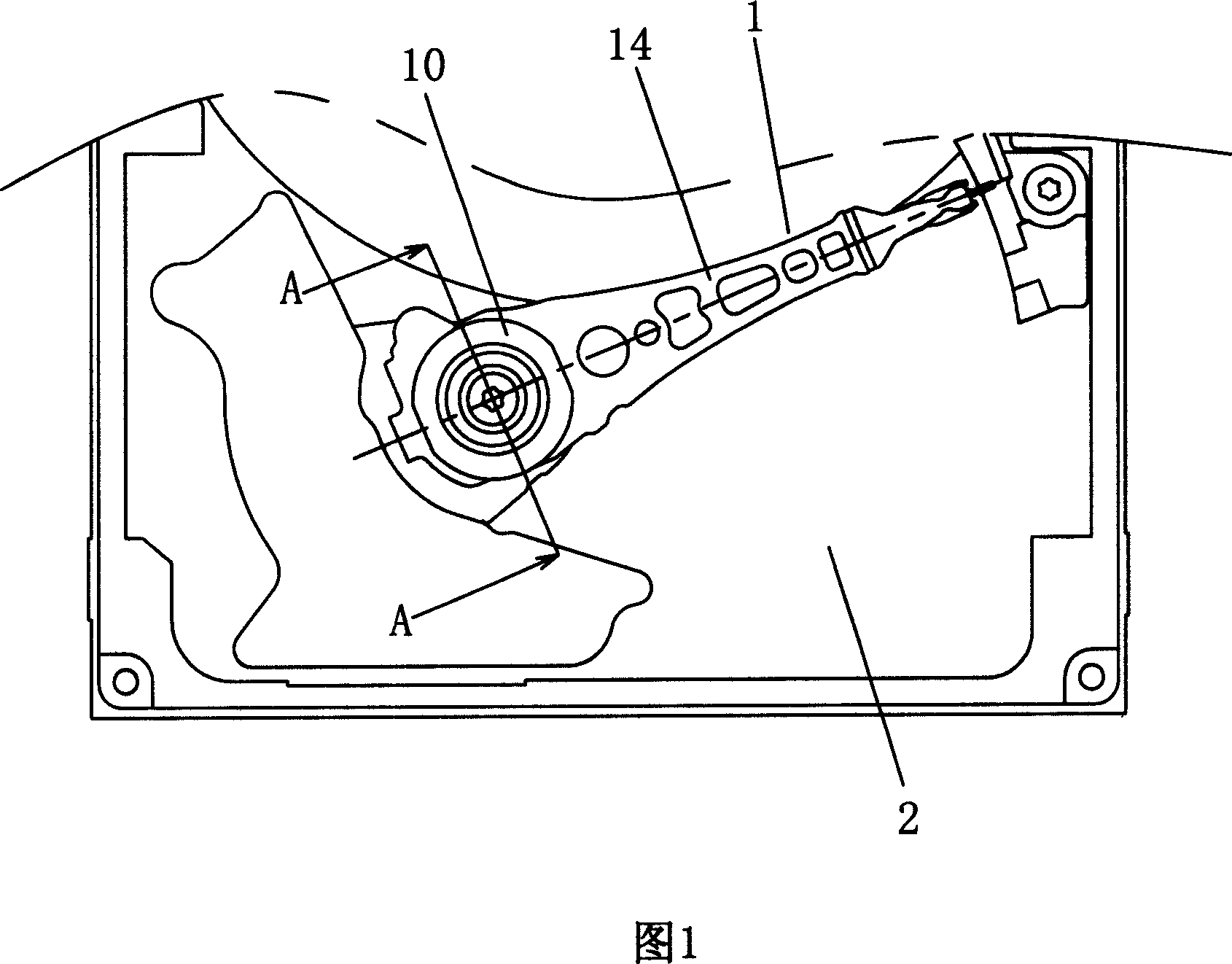

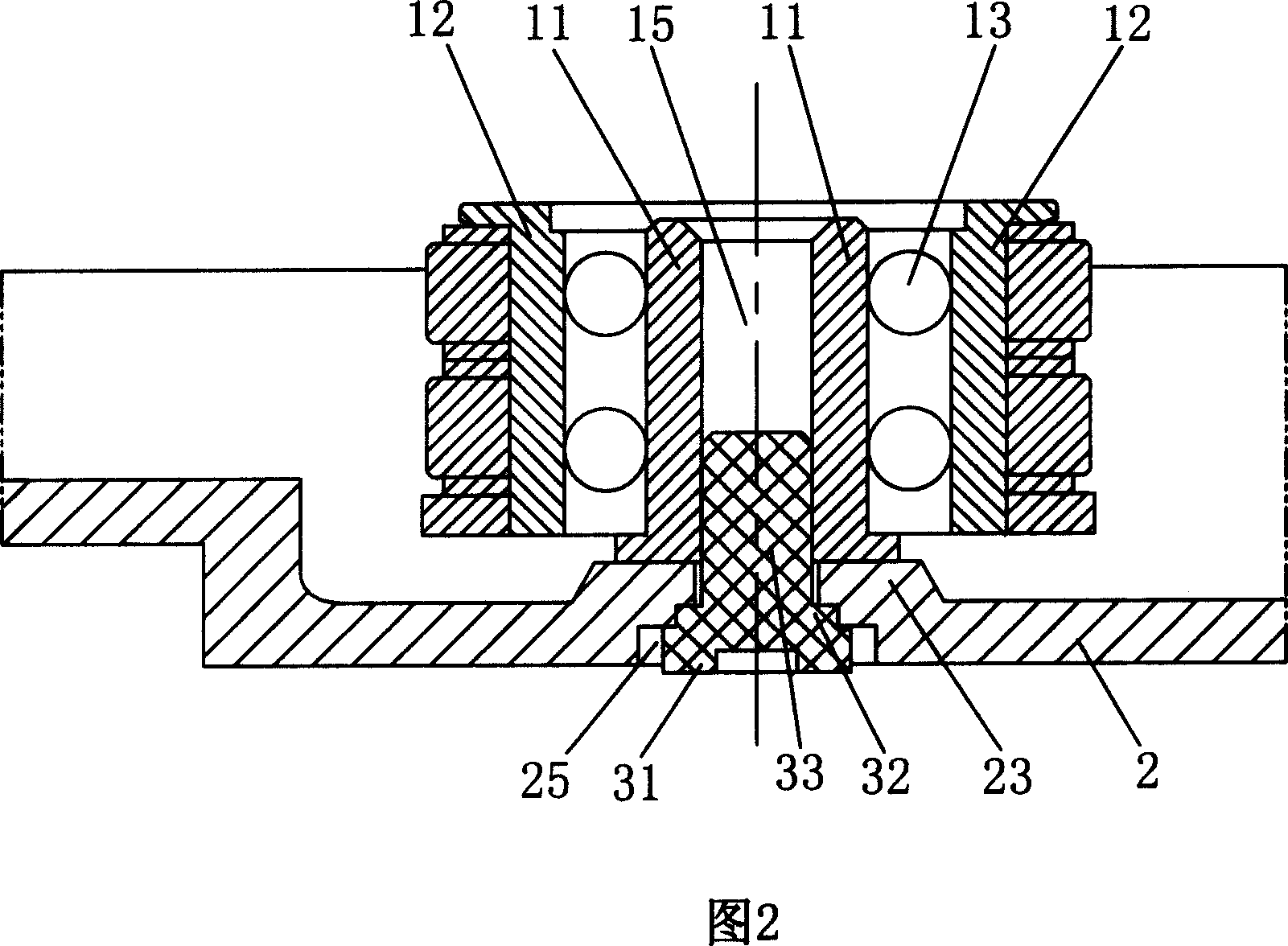

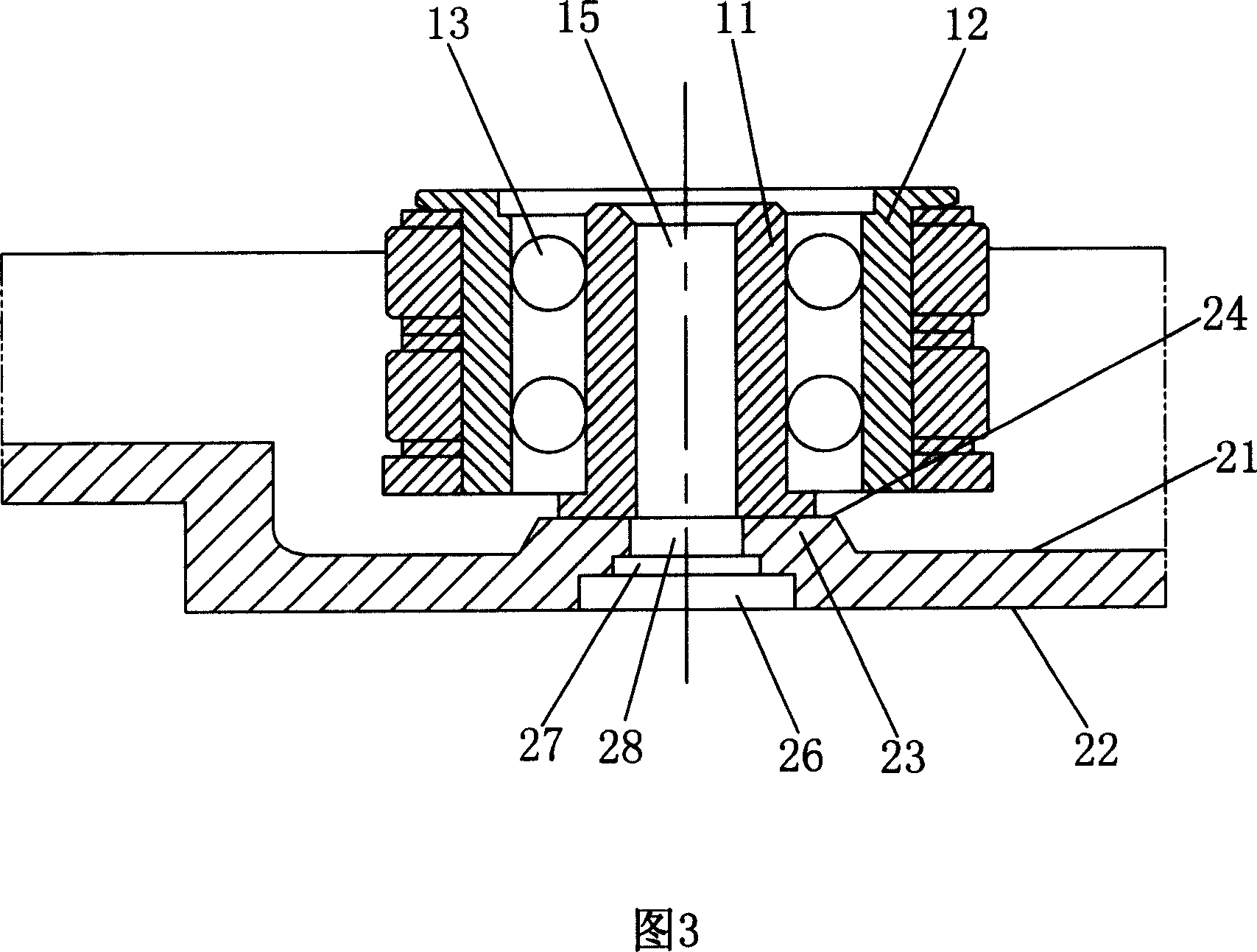

[0013] Referring to FIG. 1 to FIG. 4 , the magnetic head assembly positioning structure of the present invention includes a magnetic head assembly 1 , a hard disk base 2 and a fastener 3 . The magnetic head assembly 1 includes a rotating shaft set 10 and at least one magnetic head 14. The rotating shaft set 10 includes a rotating shaft 11, a rotating shaft sleeve 12 and a bearing 13. The inner ring of the bearing 13 is fixed to the rotating shaft 11, and the inner ring of the rotating shaft sleeve 12 is fixed to On the outer ring of the bearing 13 , the magnetic head 14 is fixedly sleeved on the outer ring of the rotating shaft sleeve 12 , so that the magnetic head 14 can rotate relative to the rotating shaft 11 along with the rotating shaft sleeve 12 . The hard disk base 2 has an upper surface 21 and a lower surface 22, a boss 23 protrudes from an appropriate position of the upper surface 21, and a stepped groove 25 is formed through the upper surface 24 of the boss and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com