Composite heat resisting antioxidant for polyolefin and its production process and application

An antioxidant, polyolefin technology, applied in the fields of fine chemicals and polymer materials, can solve problems such as accelerated aging

- Summary

- Abstract

- Description

- Claims

- Application Information

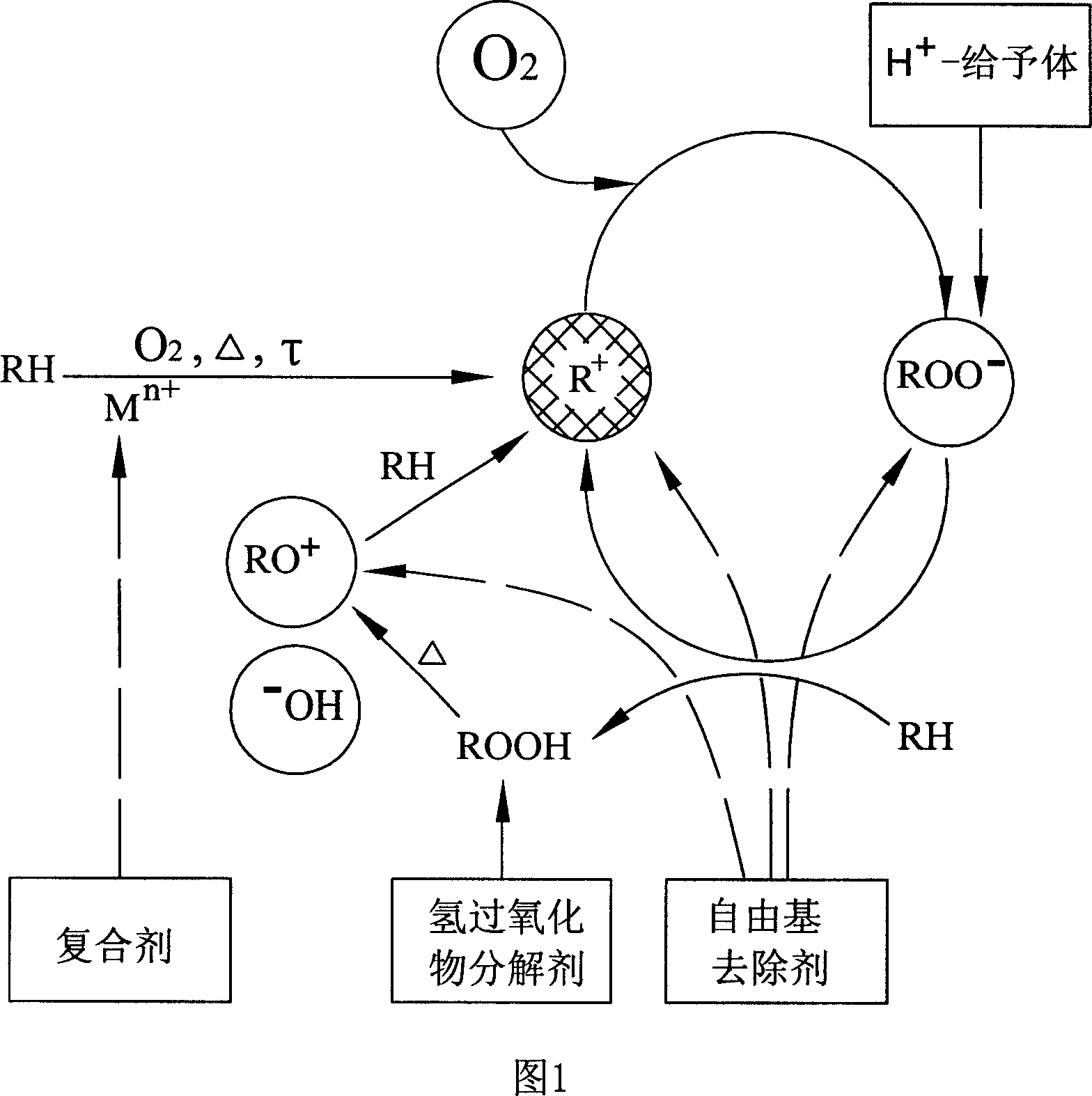

AI Technical Summary

Problems solved by technology

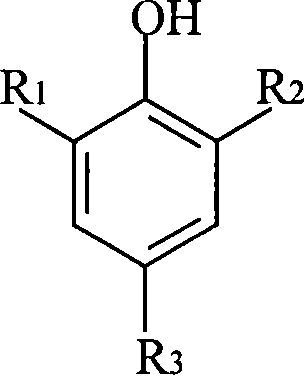

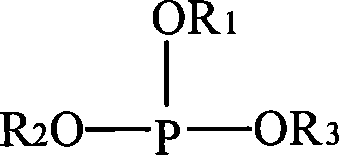

Method used

Image

Examples

Embodiment 1

[0051] The component contents in the following formulations are all calculated by weight percentage.

[0052] Formula 1 of new polyolefin high-efficiency heat-resistant and oxidation-resistant compound antioxidant:

[0053] Tetra[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 60%;

[0054] Pentaerythritol bis-diphosphite bis(2,4-di-tert-butylphenyl) 20%;

[0055] 1,2-bis(2-hydroxybenzoyl) hydrazine; Disalicylic hydrazide 20%.

[0056] Formula 2 of new polyolefin high-efficiency heat-resistant and oxidation-resistant composite antioxidant:

[0057] n-octadecyl β-(4-hydroxy-3,5-di-tert-butylphenyl)propionate 40%;

[0058] Pentaerythritol bisphosphite di(stearyl alcohol) 30%;

[0059] N,N'-Diacetylthiodipropionyldihydrazine 30%.

[0060] New Polyolefin Efficient Thermal Oxidation Composite Antioxidant Formula 3:

[0061] 2,2'-methylenebis(4-methyl-6-tert-butylphenol) 30%;

[0062] Tris(2,4-di-tert-butylphenyl)phosphite 60%;

[0063] Bis(3,5...

Embodiment 2

[0073] Embodiment 2 (application in PP products)

[0074] TINUVIN783 (produced by Ciba Refined Chemical Company, referred to as 783) whose light stabilization effect is significantly lower than that of CHIMASSORB 944 (produced by Ciba Refined Chemical Company, referred to as 944) and the new polyolefin high-efficiency heat-resistant oxidation composite antioxidant AO of the present invention are used together In polypropylene, compared with the composite system of CHIMASSORB 944, TINUVIN 622 (produced by Ciba Refined Chemical Company, referred to as 622) and general antioxidant IRGANOX B-215 (produced by Ciba Refined Chemical Company, referred to as B-215), the Photo-oxidative aging properties and thermo-oxidative aging properties.

[0075] Using PP (domestic model as F1002) powder as the base resin, add 0.3% 622 / 0.15% B-215 (1 # ), 0.3% 944 / 0.15% B-215 (2 # ), 0.3%783 / 0.15AO (3 # ), and then add 0.1% calcium stearate. Put each additive and base resin in a high-speed mixer...

Embodiment 3

[0082] Embodiment 3 (at PE functional shed film)

[0083] Using 944, 783, 622 respectively with the new polyolefin high-efficiency heat-resistant oxidation composite antioxidant AO of the present invention, common composite antioxidant B-215, according to the current production formula of agricultural polyethylene functional shed film, blowing test film.

[0084] The formulations and artificial accelerated aging tests of the six test shed films are shown in Table 6 and Table 7, respectively.

[0085] 1 #

[0086] Irradiation time / hr

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com