Method for hybrid giant napier producing in oxygen free radical doffing/bleaching integrated reactor with albefaction paper stuff

A technology of free radicals and imperial bamboo grass, applied in the direction of pretreatment with oxygen-generating compounds, paper and paper making, etc., can solve the problems of affecting the cost of raw materials, increasing demand, and increasing imports of wood pulp and waste paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

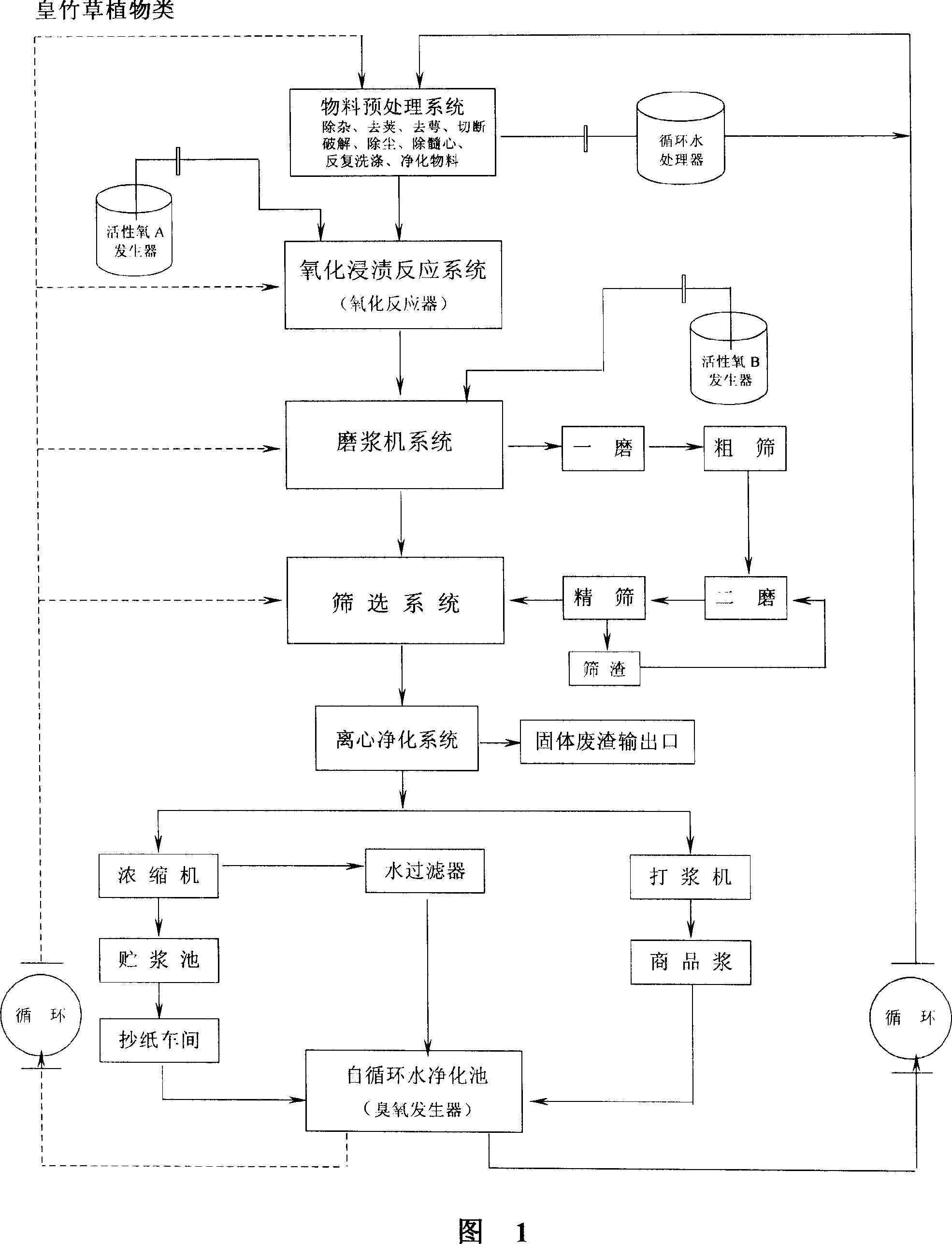

Image

Examples

Embodiment 1

[0046] A method for producing bleached pulp in an oxygen free radical de- / bleaching integrated reaction kettle comprising the following steps:

[0047] The thick fibers (tips) of the royal bamboo grass sent by the material preparation section are sent to the material preparation room by the conveyor belt for pretreatment; they are washed and dehydrated with 60°C deionized water; the slurry is fed into the oxidation reaction kettle with a screw conveyor, the model is M-O·P- Type II, and add dimethyl sulfoxide with a concentration of 0.1%; start the rotating electron accelerator and electric stirrer, the stirring speed is 1m / s, and the softening material has a stable temperature of 150°C; after opening the nitrogen gas for 3 minutes, the pre-prepared The composite oxygen pressure valve is opened, and under 0.6MPa oxygen pressure, it is 0.1% magnesium sulfate, 0.2% sodium silicate and 0.5% (H 2 o 2 ) cellulose hydrogen peroxide protective agent, 0.01% ethylenediaminetetraacetic ...

Embodiment 2

[0049] Same as Example 1, the difference is that the raw material is bamboo thick fiber (stalk), and the oxidation reactor model is M-O P-III type; it is washed and dehydrated with 80°C deionized water; the stirring speed is 0.8m / s; the softened material is stable The temperature is 170°C; 0.01% ferric oxide and 0.4% hydrogen peroxide (H 2 o 2 ) cellulose protective agent, a concentration of 0.5% sodium polyphosphate oxygen stabilizer, a concentration of 0.6% sodium peroxycarbonate oxygen stabilizer; reaction 60min, pH value is 4.5; use pulp washer in 80 ℃ deionized water The pulp is repeatedly washed two to three times, dehydrated and left standing, and stored in deionized water containing 0.01% N,N-dibenzylhydroxylamine to obtain a pulp with a pulp yield of 74% and a whiteness of 75.5% ISO.

Embodiment 3

[0051] The same as Example 1, the difference is that the raw material is the mixed crude fiber (tip + stalk) of the royal bamboo grass, and the oxidation reactor model is M-O·P-III type; it is washed and dehydrated with 70°C deionized water; the stirring speed is 0.8m / s; softening material stable temperature is at 165 ℃; Add concentration under 0.8Mpa oxygen pressure and be 0.1% MetSulphate, 0.2% sodium silicate and 0.5% hydrogen peroxide (H 2 o 2) cellulose protective agent, dimethyl sulfoxide oxygen stabilizer with a concentration of 0.3%; react for 45 minutes, and the pH value is 3.8; use a pulp washer to repeatedly wash the pulp in 70°C deionized water for two to three times, dehydrate and stand still, and Containing 0.01% N, N-dibenzylhydroxylamine and storing in deionized water, a slurry with a yield of 75% and a whiteness of 76% ISO can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com