Dynamic assembly suspension device

A powertrain and suspension technology, applied in the field of auto parts, can solve problems such as unreasonable design and poor vibration and noise reduction effects, and achieve good vibration and noise reduction effects, prolong service life, and be easy to popularize and apply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

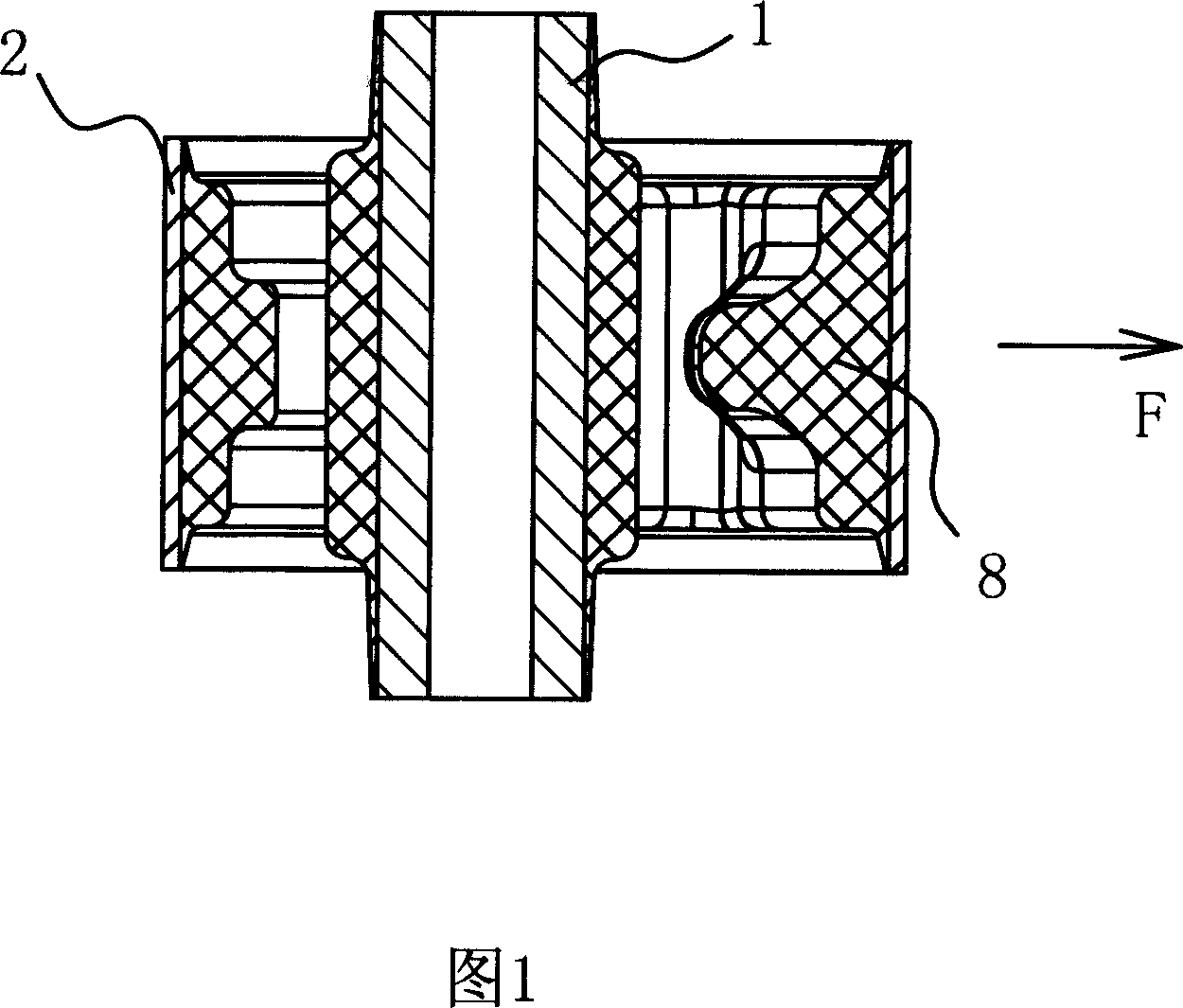

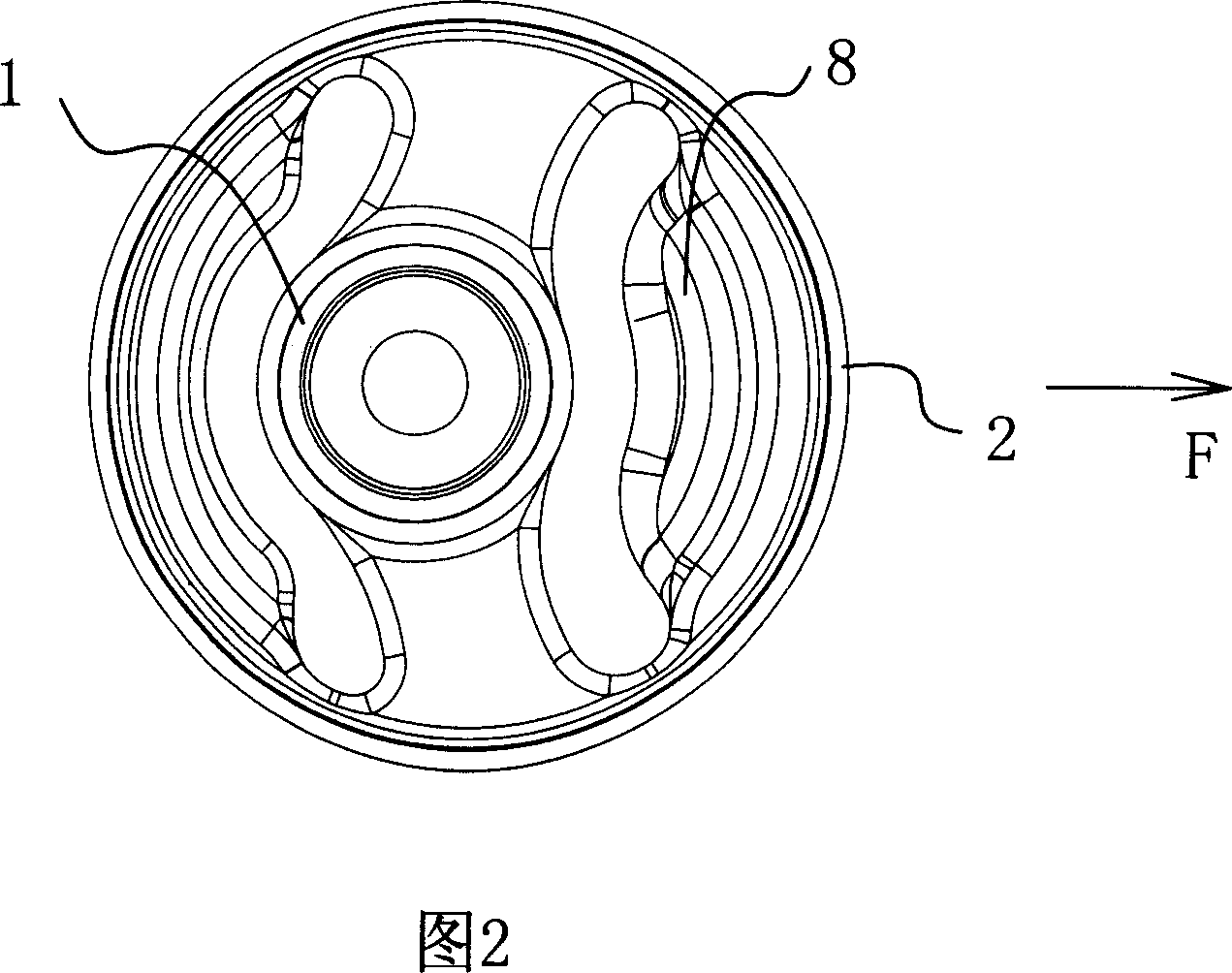

[0028] The powertrain suspension device shown in FIG. 4 and FIG. 5 includes an inner tube 1 , an outer tube 2 arranged outside it, and an intermediate tube 3 is arranged between the inner tube 1 and the outer tube 2 . The outer tube 2 is cylindrical, the middle tube 3 is cylindrical, and they are arranged concentrically; and the periphery of the inner tube 1 is square. A first elastic body 4 is arranged between the inner pipe 1 and the middle pipe 3 , and a second elastic body 5 is arranged between the middle pipe 3 and the outer pipe 2 . Both the first elastic body 4 and the second elastic body 5 are made of rubber. The first elastic body 4 is provided with two axially arranged through holes 6 arranged uniformly, and the second elastic body 5 is provided with four axially arranged evenly arranged through holes 6 . The cross-sectional shape of the through hole 6 is large at both ends and small at the middle. The upper and lower ends of the inner tube 1 are provided with prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com