Fluorine-containing polyimide basal body resin and preparation method thereof

A fluorine-containing polyimide matrix, polyimide matrix technology, applied in the field of polyimide resin and its preparation, can solve the need to improve melt processing performance, poor impact toughness of composite materials, easy to produce microcracks, etc. problems, to achieve the effect of improving long-term thermal oxidation stability, good molding processability, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

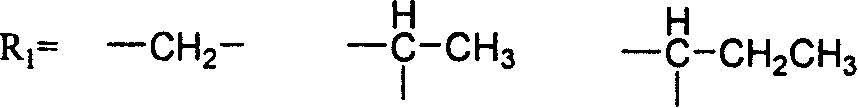

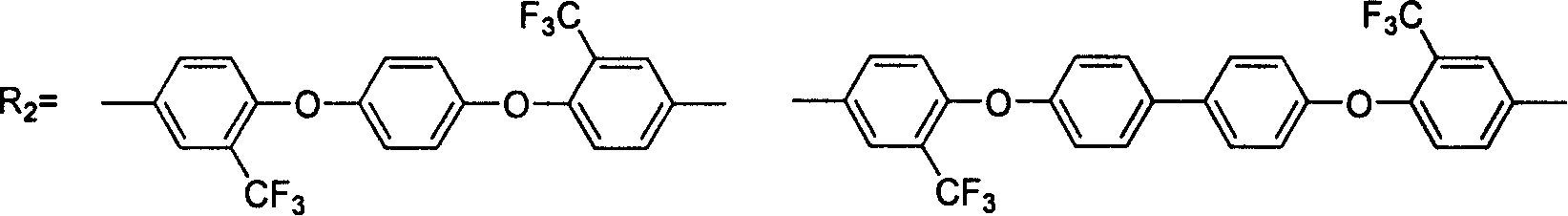

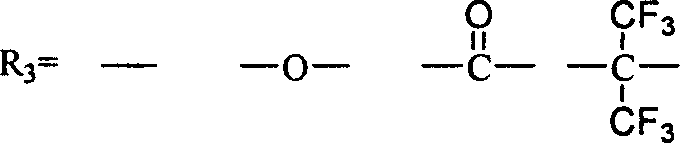

Method used

Image

Examples

Embodiment 1

[0028] 80 parts of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) was heated to reflux in 100 parts of ethanol for 3 hours to obtain the corresponding aromatic diacid diester solution (BTDE). Heat 35 parts of end-capping agent NA acid anhydride in 55 parts of ethanol to reflux for 3 hours to obtain the corresponding monoacid monoester solution (NE). Dissolve 80 parts of organic diamine monomer (6FAPB) in 60 parts of ethanol, and after stirring for half an hour, add the above-prepared NE and BTDE solutions sequentially; the mixture is stirred at 50°C for 5 hours to obtain 47% solid content Polyimide matrix resin solution; its absolute viscosity (25°C) is 20-35mPa.s.

[0029] The viscous liquid obtained after the resin solution is rotary evaporated at 60-80° C. to remove most of the solvent is heated and dried (50-220° C.) to obtain resin molding powder. Put 50g of molding powder into the mold, heat it in a press preheated to 250°C, pressurize at 270-300°C to 1-10MPa, conti...

Embodiment 2

[0031] 121 parts of 3,3',4,4'-diphenyl ether tetra-acid dianhydride (ODPA) were heated to reflux in 200 parts of ethanol for 1 hour to obtain the corresponding aromatic diacid diester solution (ODPE). Heat 40 parts of the end-capping agent NA acid anhydride in 55 parts of ethanol to reflux for 5 hours to obtain the corresponding monoacid monoester solution (NE). Dissolve 185 parts of diamine monomer 6FBAB in 160 parts of ethanol, stir for half an hour, then add the previously prepared NE and BTDE solutions in turn, and stir the mixture at 5°C for 15 hours to obtain polyamide with a solid content of 45%. imine homogeneous resin solution. Its absolute viscosity (25°C) is 15-35mPa.s.

[0032] The viscous liquid obtained after the resin solution is rotary evaporated at 60-80° C. to remove most of the solvent is heated and dried (50-220° C.) to obtain resin molding powder. Put 50g of molding powder into the mold, heat the mold in a press preheated to 250°C, pressurize 1-10MPa at ...

Embodiment 3

[0034] 400 parts of 3,3',4,4'-benzophenone tetra-acid dianhydride (BTDA) were heated to reflux in 620 parts of ethanol for 3 hours to obtain the corresponding aromatic diacid diester solution (BTDE). Heat 52 parts of end-capping agent NA acid anhydride in 64 parts of ethanol to reflux for 2 hours to obtain the corresponding monoacid monoester solution (NE). Dissolve 356 parts of diamine monomer 6FAPB in 400 parts of ethanol, stir for half an hour, then add the NE and BTDE solutions prepared above in turn, and stir the mixture at 20°C for 10 hours to obtain a polyamide with a solid content of 43%. imine homogeneous resin solution. Its absolute viscosity (25°C) is 15-35mPa.s.

[0035]Composite the matrix resin solution with carbon fiber on a winding machine to prepare prepregs. After most of the solvents are volatilized, laminate them according to the requirements. Stages of prepreg (tape or cloth). Put the prepreg in stage B into a press preheated to 260°C, apply a pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com