Double-functional group ionic liquid and preparation method

An ionic liquid and bifunctional technology, which is applied in the synthesis of bifunctional ionic liquids and the field of bifunctional ionic liquids, can solve the problems of difficult control of reaction conditions, expensive raw materials, complicated preparation steps, etc., and achieves easy purification, The effect of being stable in contact with water and air and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Dimethylethanolyl 3-sulfonate propylammonium inner salt

[0044] Under the condition of ice bath and stirring, slowly add 8.8mL of 1,3-propane sultone (0.1mol) dropwise into 30mL of acetone mixed solution containing 10.1mL of N,N-dimethylethanolamine (0.1mol), namely The molar ratio of the reaction materials was 1:1, and a white solid precipitated out soon. After 1 hour, the white solid was washed with acetone and ether three times, filtered, and dried under vacuum at 50°C. The reaction equation is:

[0045]

Embodiment 2

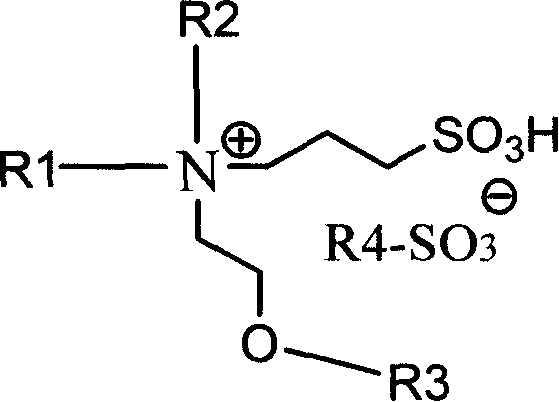

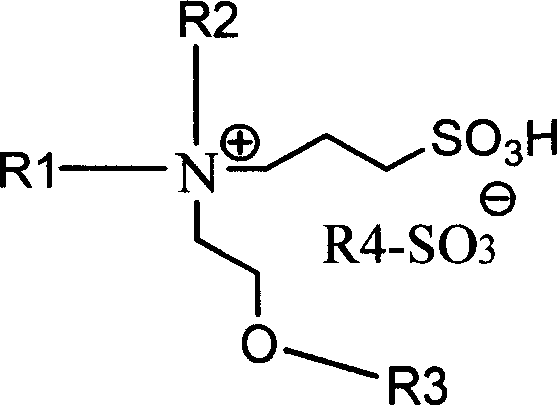

[0047] [p-Toluenesulfonic acid][Dimethylethanolyl 3-propylammoniumsulfonate] ionic liquid

[0048] Under ice-bath and stirring conditions, 1.95g (0.01mol) of the dimethylethanolyl 3-sulfonate propylammonium inner salt obtained in Example 1 and 1.81g p-toluenesulfonic acid (0.01mol) were mixed, and after 3 hours, Heating to 70°C until it becomes liquid, then vacuum drying after cooling. The product is a colorless transparent liquid, and the reaction equation is:

[0049]

Embodiment 3

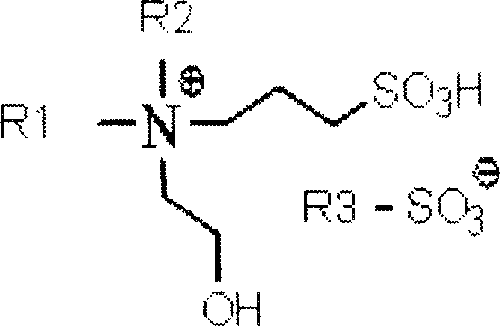

[0051] [Trifluoromethanesulfonic acid][Dimethylethanolyl 3-propylammoniumsulfonate] ionic liquid

[0052] N 2 Under the conditions of atmosphere, ice bath and electric stirring, 1.80mL of trifluoromethanesulfonic acid (0.02mol) was slowly added dropwise to 4.23g (0.02mol) of the dimethylethanolyl 3-sulfonate propylammonium obtained in Example 1 In the internal salt, after 12 hours, heat to 50°C until all of it becomes liquid, and then vacuum dry after cooling. The product is light yellow transparent liquid, and the reaction equation is:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com