A secure lithium icon battery, improving method and making method of its anode slice

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of safe lithium-ion batteries, and can solve problems such as the safety factor is difficult to meet the standard, the battery cannot pass the short-circuit test, and the current is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

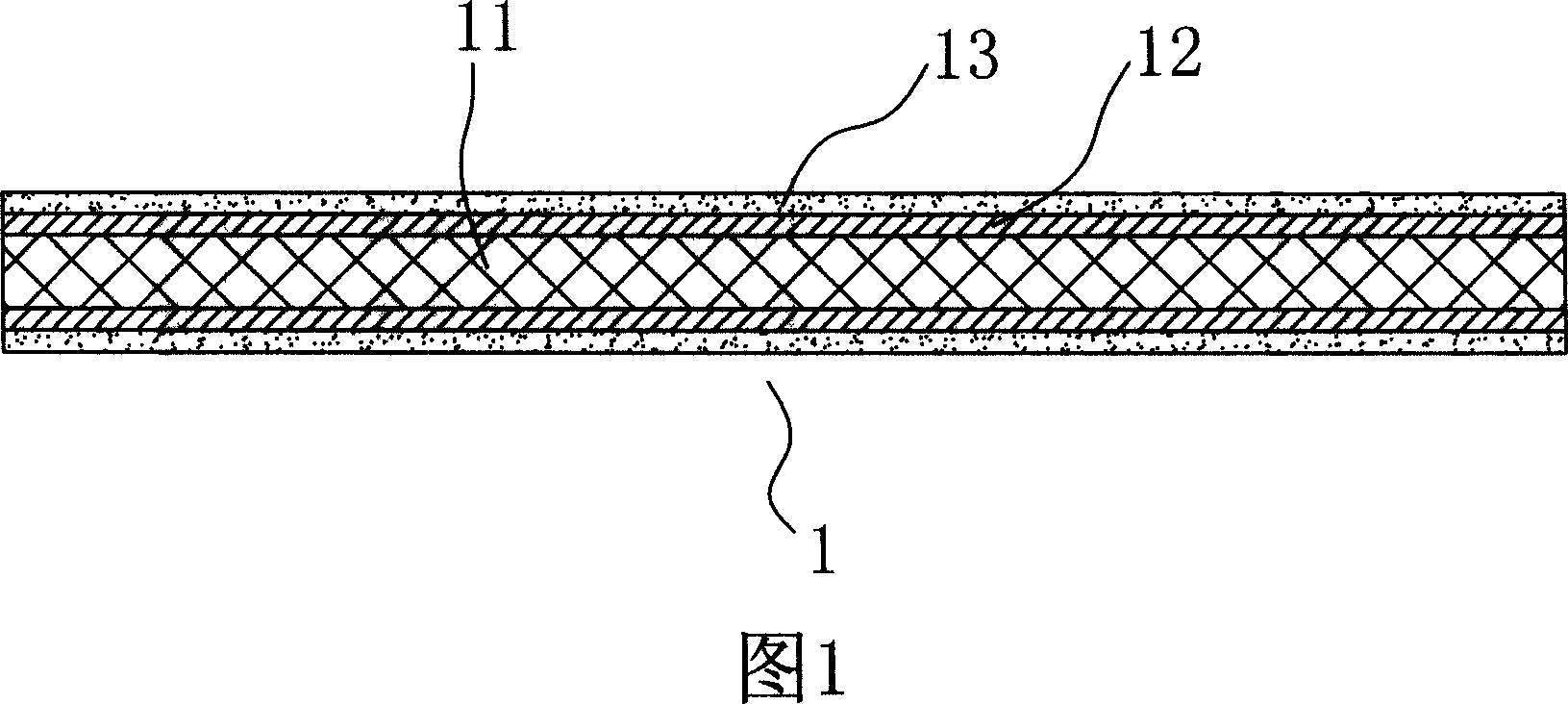

[0021] See Figure 1, below with AL 2 o 3 , as an example to illustrate the present invention. As mentioned above, the method adopted in the present invention to improve the safety performance of the lithium-ion battery is to increase the resistance of the surface of the anode sheet and reduce the thermal conductivity of the anode, so that the lithium-ion battery can successfully pass the short-circuit test and improve the safety performance of the product. When making this lithium-ion battery, other steps are the same as the current manufacturing process of ordinary lithium-ion batteries, the difference is that the following methods need to be used when making the anode sheet:

[0022] First, make the base of the anode sheet. The anode sheet base includes an anode current collector 11 and a membrane 12 attached thereon with an anode active substance. The anode current collector 11 is generally made of copper foil. The active material is mixed in a solvent to form a homogen...

Embodiment 2

[0035] The present invention will be described below by taking Li2O as an example. As mentioned above, the embodiment is the same as the anode sheet manufacturing process of the above embodiment, and also includes the following three steps:

[0036] First, make the base of the anode sheet. The anode plate base includes an anode current collector and a membrane attached thereon with an anode active substance.

[0037] Next, make a ready-to-coat slurry. Powdered Li2O is mixed with a binder solvent and dissolved in the solvent to form a slurry. Solvent adopts organic solvent. where AL 2 o 3 The mass ratio of mixing with binder is 90-95:10-5.

[0038] Finally, dipping or coating the prepared anode sheet substrate into the slurry, and then drying the anode sheet to evaporate the solvent, so that a layer of slurry film is formed on the surface of the anode sheet substrate. The drying temperature can be selected to dry at room temperature.

[0039] The anode sheet produced in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com