Method of preparing ozone by low-voltage electrolysis method

A low-voltage electrolysis and ozone technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of low ozone concentration, inconvenient movement, and low ozone output, and achieve the effects of high ozone concentration, low production cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

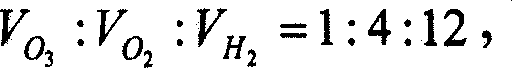

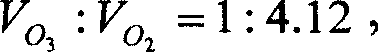

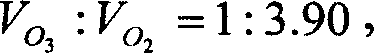

[0028] In a diaphragmless electrolyzer, a neutral phosphate solution is added as the electrolyte, where K 2 HPO 4 with KH 2 PO 4 The concentrations are 2.0mol / L and 1.0mol / L respectively, and the stainless steel electrode is used as the cathode (with an area of 15dm 2 ), the titanium matrix fluorine-containing lead dioxide electrode is the anode (with an area of 10dm 2 ), using 100, 400, 600, 800, 1000, 1500, 2000A / m respectively 2 The current density of the current density is determined by the iodometric method to measure the ozone flow rate. During electrolysis, the electrolyte and the electrode are forced to cool the electrolyte with a refrigeration device. result.

[0029] Current densityA / m 2

Embodiment 8~13

[0031] In the electrolyzer with example 1~7, adopt identical electrolytic solution, embodiment 8~10 is anode (area is 10dm2) with titanium substrate fluorine-containing lead dioxide electrode 2 ), with nickel alloy, graphite, and lead alloy as cathodes respectively (with an area of 15dm 2 ); Embodiment 11~13 is negative electrode with graphite, is anode respectively with the fluorine-containing lead dioxide composite electrode of titanium matrix, graphite matrix and ceramic matrix, all adopts the electric current electrolysis of 80A, measures the ozone flow that produces with iodometric method, During electrolysis, the electrolyte and electrodes were forcibly cooled by a refrigeration device, and the temperature of the electrolyte was controlled between 5 and 35°C to prepare ozone by electrolysis. The results shown in Table 2 can be obtained.

[0032] Embodiment 8~10

Embodiment 14~15

[0034] In the non-diaphragm type electrolyzer, add the selenic acid of the neutral phosphate composite solution such as embodiment 1 and 2.0mol / L respectively as electrolytic solution, graphite electrode is negative electrode (area is 5dm 2 ), the ceramic matrix fluorine-containing lead dioxide electrode is the anode (with an area of 2.5dm 2 ), using 20A current electrolysis. The ozone flow rate is measured by the iodometric method. During electrolysis, the electrolyte and the electrode are cooled by water flow, and the temperature of the electrolyte is controlled between 5 and 35°C for electrolysis. The ozone flow rate obtained is 4.45g / h and 1.15g / h respectively. h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com