Sintering flue gas ammonia method desulfurizing system

An ammonia desulfurization and sintering flue gas technology, applied in the field of flue gas desulfurization, can solve the problems of high operation cost, large steam consumption, low oxidation efficiency, etc., and achieve the effects of no secondary pollution, saving heat consumption and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

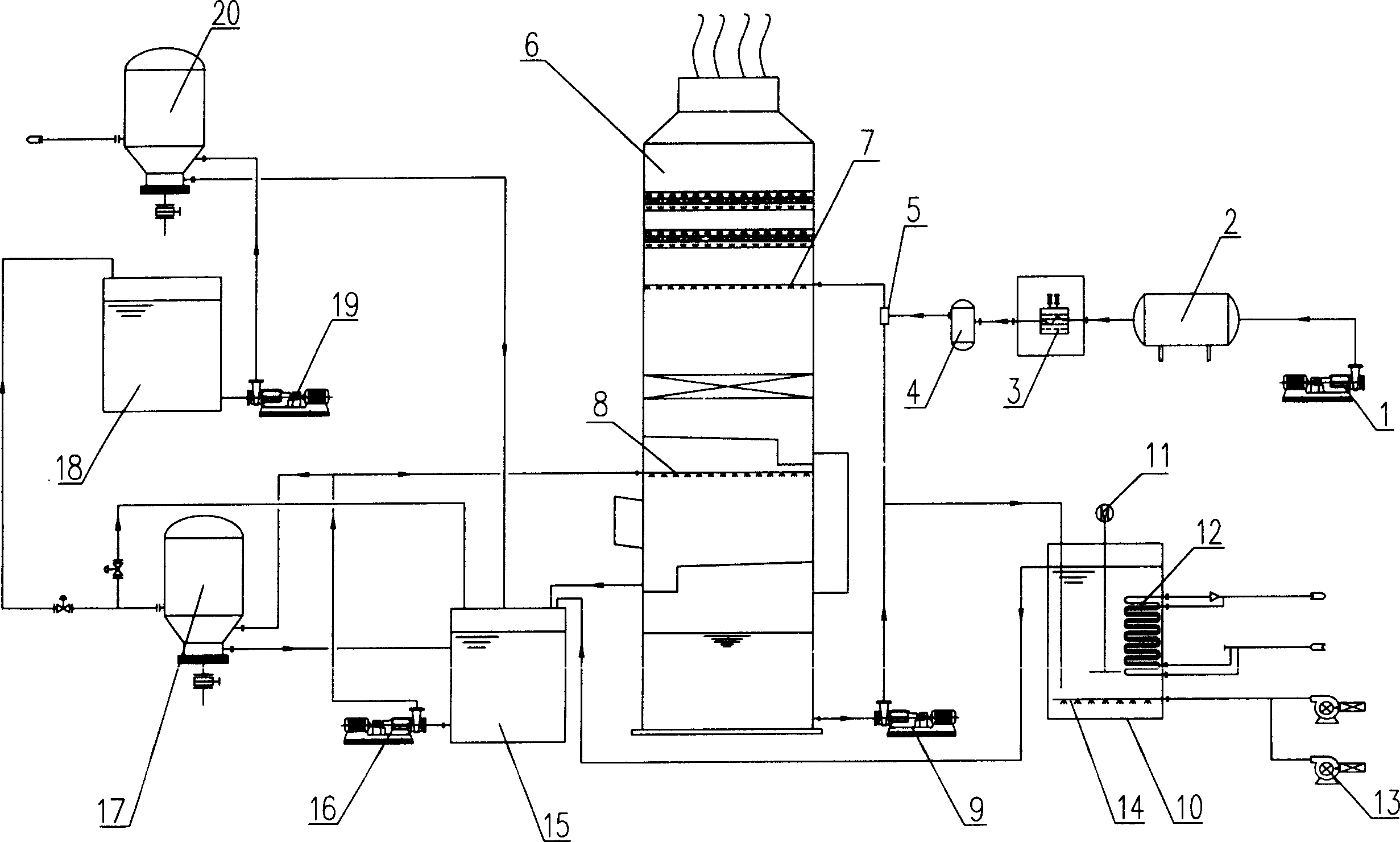

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] see Attachment

[0010] The liquid ammonia is transported to the desulfurization site by a closed tanker, and the liquid ammonia is sent to the liquid ammonia tank 2 through the ammonia unloading pump 1 for storage. After being heated by the liquid ammonia vaporizer 3, the liquid ammonia is vaporized and sent to the ammonia gas storage tank 4, and the ammonia gas in the ammonia gas storage tank 4 is connected to the mixer 5 through a pipeline for the desulfurization tower 6 to use ammonia gas. The sintering plant can use the waste ammonia water produced during the sintering process as a desulfurizing agent, and add it to the desulfurization tower 6 and the oxidation tank 10 for reaction. The desulfurization tower 6 is a three-stage desulfurization tower. A circulation pump 9 is installed outside the desulfurization tower 6. The circulation pump 9 send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com