Composite heat insulation plate

A technology of composite thermal insulation and thermal insulation layer, which is applied in the direction of thermal insulation, floors, building components, etc. It can solve the problems of complex construction process, poor durability and fireproof performance, and poor bonding ability of the base wall of the external thermal insulation system. Achieve the effects of shortening the construction period, fast installation speed and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

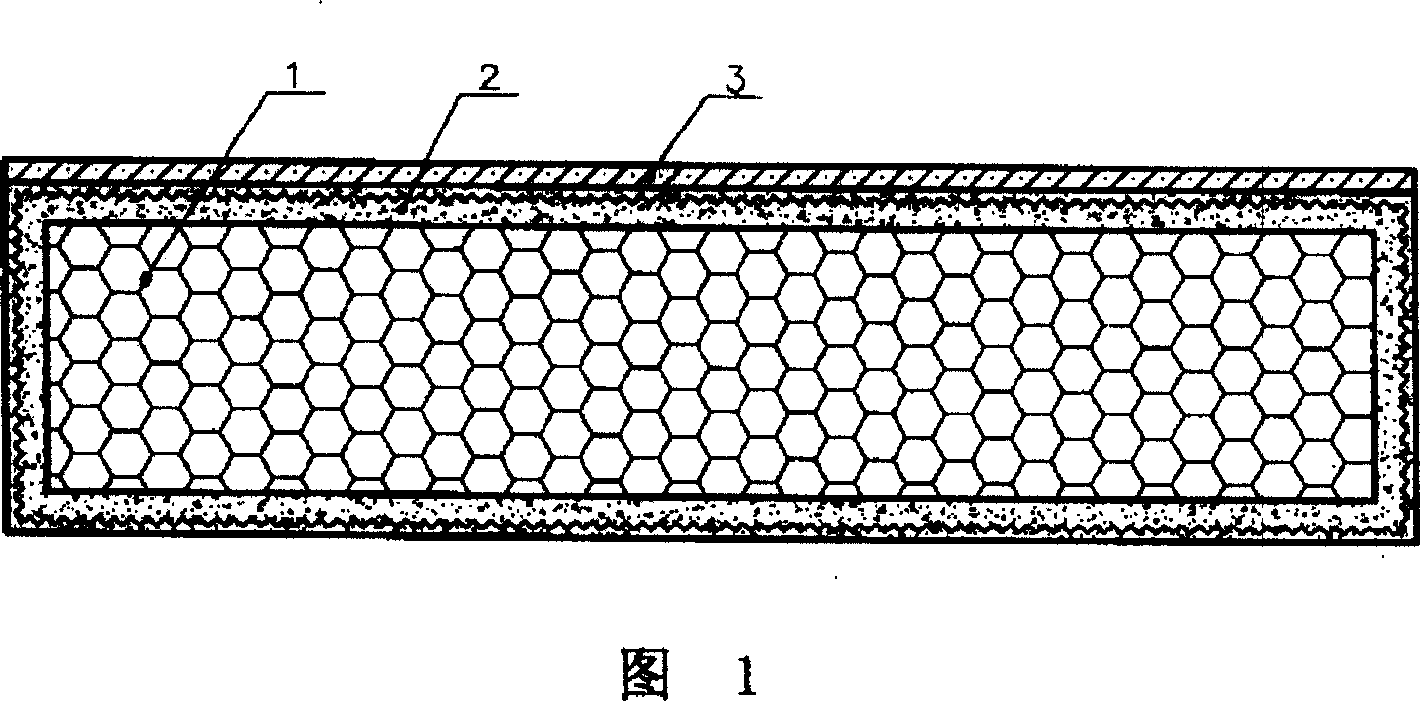

[0012] Embodiment 1: As shown in Figure 1, the composite thermal insulation board of the present invention is composed of a thermal insulation layer 1, a reinforced protective layer 2 and a finishing layer 3. Insulation layer 1 is expanded polystyrene board (EPS); reinforced protective layer 2 is composed of non-cement-based polymer mortar and a layer of glass fiber mesh cloth; facing layer 3 is putty on the upper surface of reinforced protective layer 2 , Spray or brush paint.

Embodiment 2

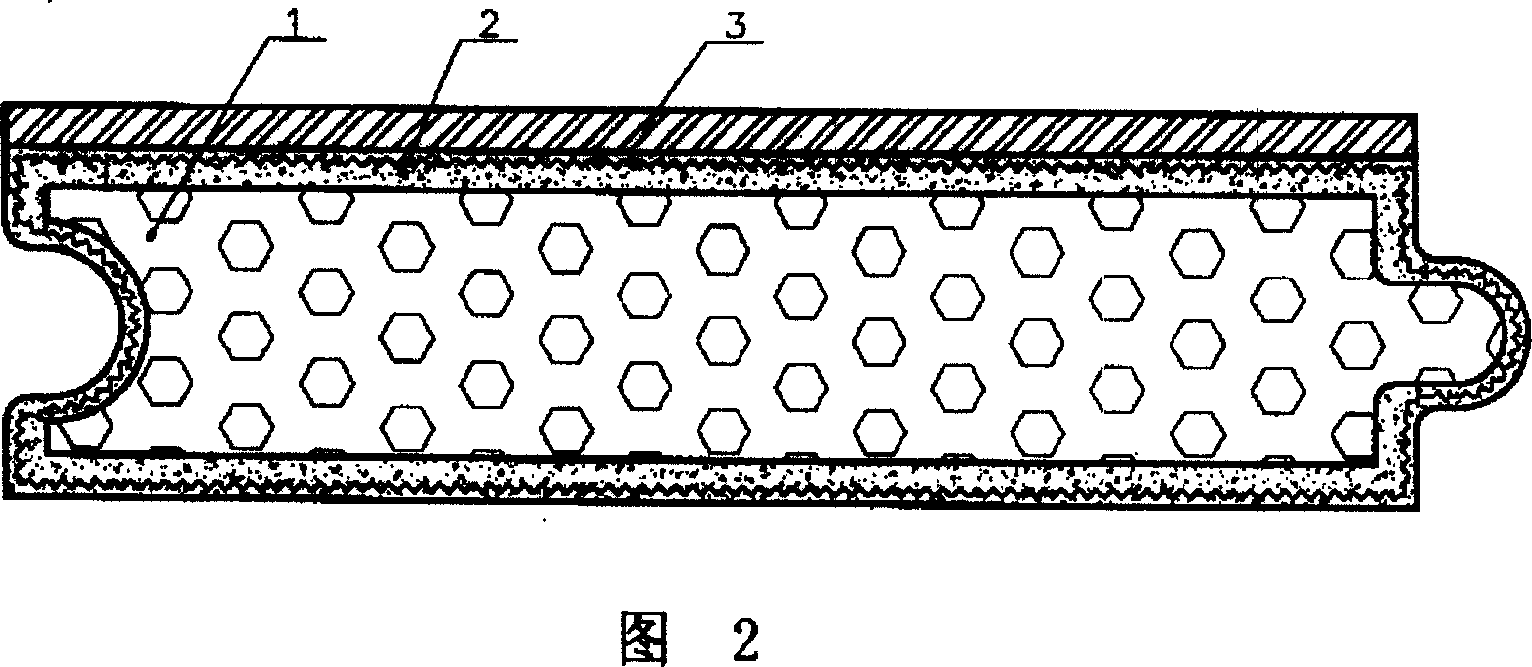

[0013] Embodiment 2: As shown in Figure 2, the composite thermal insulation board of the present invention is composed of a thermal insulation layer 1, a reinforced protective layer 2 and a finishing layer 3. Insulation layer 1 is extruded polystyrene board (XPS); reinforced protective layer 2 is polymer cement mortar, and there is a layer of galvanized steel wire mesh inside the reinforced protective layer 2; the decorative layer 3 is a ceramic tile pasted on the reinforced protective layer 2 .

Embodiment 3

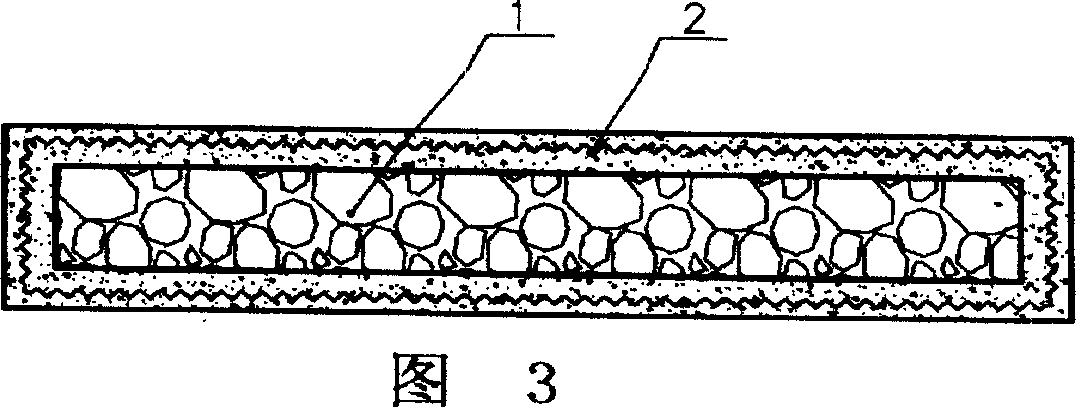

[0014] Embodiment 3: As shown in Figure 3, the composite thermal insulation board of the present invention consists of a thermal insulation layer 1 and a reinforced protective layer 2. The insulation layer 1 is an expanded polystyrene board; the reinforced protective layer 2 is composed of polymer cement mortar and a layer of alkali-resistant glass fiber mesh cloth, and the reinforced protective layer 2 covers the entire outer surface of the insulation layer 1. As shown in Figure 4, stack two composite thermal insulation boards with the same length and width in Figure 3, and move them along the diagonal line of the upper surface, stagger them for a certain distance, and then bond them together. For lap connection, electricity can be used as a place to install anchor bolts or expansion bolts. As shown in Figure 5, the finishing layer 3 is made by scraping putty, spraying or brushing paint on the upper surface of the composite thermal insulation board shown in Figure 4, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com