Infrared shielding film-coated glass plate and process for its production

A technology of infrared shielding and glass plate, applied in coatings, optical filters, etc., can solve the problems of uneconomical and infrared shielding loss, and achieve the effects of reduced dosage, high radio wave transmittance, and low infrared transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

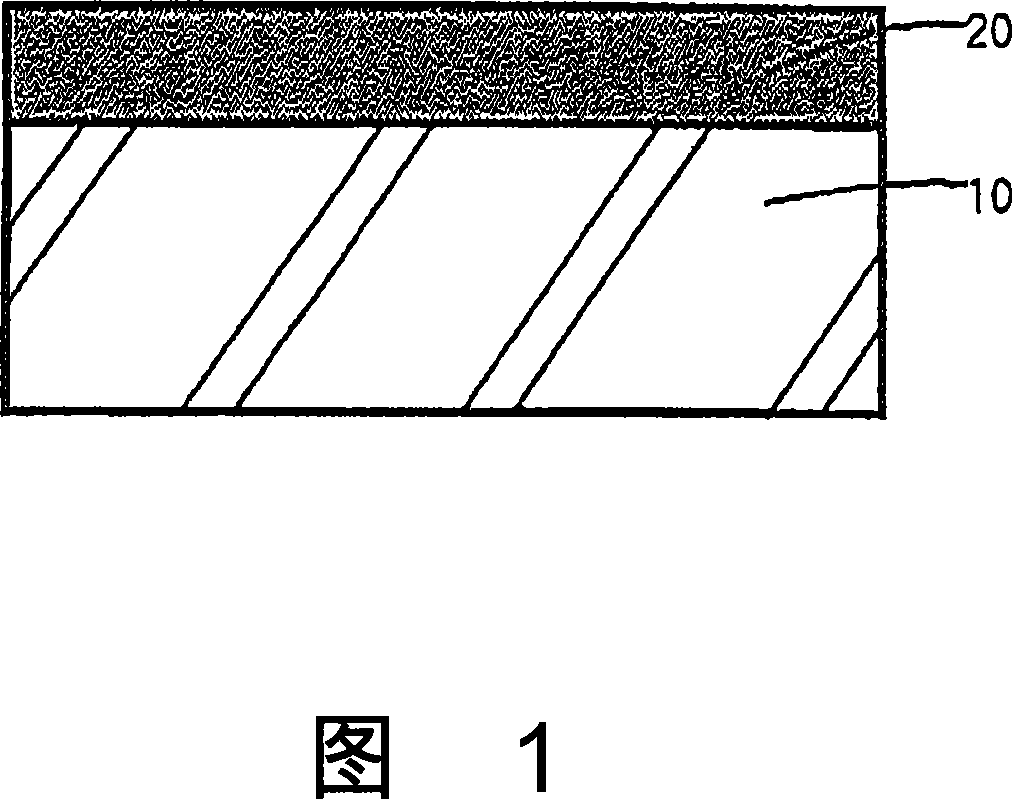

Image

Examples

Embodiment 1

[0073] Weigh 0.71 gram of xylene dispersion A (wherein 30 mass % of average primary particle diameters are dispersed with cubic fine ITO microparticles (Fuji Titanium Industry Co., Ltd. production) of 40 nm) and 2.15 grams of xylene solution B (wherein Containing 20% by mass of perhydropolysilazane (number average molecular weight: 1,000, trade name Aquamica NP-110, manufactured by AZ Electronic Materials)), they were mixed at room temperature and stirred for 10 minutes to prepare coating liquid C.

[0074] The prepared coating solution C is coated on the surface cleaned ultraviolet-absorbing green glass (Tv: 73%, Te: 45%, the transmittance to the light of wavelength 2.0 microns: 47%, long 10 cm, 10 cm wide, 5 mm thick, common name UVFL, produced by Asahi Glass Company, Limited), dried in ambient air at 100°C for 10 minutes, and then cured in an oven at 210°C for 30 minutes to prepare a coating with Glass plate with infrared shielding film. The properties of the prepared gl...

Embodiment 2

[0077] Take by weighing 0.71 gram of xylene dispersion liquid D (wherein the average primary particle diameter that is dispersed with 30 mass % is the hexagonal fine ITO particle (Fuji Titanium Industry, Co., Ltd. produces) of 29 nanometers) and 2.15 gram of above-mentioned solution B, they Mix at room temperature and stir for 10 minutes to prepare coating liquid E.

[0078] A glass plate coated with an infrared shielding film was prepared in the same manner as in Example 1, except that the coating solution E above was used instead of the coating solution C. Table 1 lists the evaluation results of the prepared glass plate coated with the infrared shielding film.

Embodiment 3

[0080] Weigh 0.48 g of the above-mentioned dispersion liquid A, 1.51 g of the above-mentioned solution B and 0.99 g of diisopropoxybis(ethyl acetoacetate)titanium, mix them at room temperature, and stir for 10 minutes to prepare the coating liquid F.

[0081] A glass plate coated with an infrared shielding film was prepared in the same manner as in Example 1, except that the above-mentioned coating liquid F was used instead of coating liquid C, and the film thickness of the infrared shielding film after curing changed as shown in Table 1 . The property evaluation results of the prepared glass plate coated with the infrared shielding film are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com