Self-bonding coating composition

A composition, self-adhesive technology, applied in the direction of coating, metal material coating process, nanotechnology for materials and surface science, etc., can solve the problem of coating without adhesion function, etc., to enhance mechanical stress resistance , excellent adhesive strength, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of coatings based on aqueous compositions according to the invention

[0058] An aqueous dispersion consisting of bisphenol A type epoxy resin with a solids content of 51% to 55% and 7% of 1-methoxy-2-propanol and less than 3% of benzyl alcohol and water was used as the adhesive. The amount of micronized dicyandiamide (calculated based on 100 parts of 100% solid epoxy resin) is shown in Table 1. Then add 2 parts by weight of flow reagent BYK -341 and 12 parts by weight of diethylene glycol monobutyl ether. Stir the mixture until it becomes homogeneous. In the last step, add the nanoparticle Aerosil in the amount shown in Table 1 R 7200.

[0059] The coating composition was applied to electrical steel sheets by rollers and forced dried by PMT (Maximum Metal Temperature) 240 to 250°C to give an active coating with a film thickness of about 4 microns. Then, the steel sheet is divided into a certain size, at 3N / mm 2 Under the pressure and PMT condition...

Embodiment 2

[0065] Preparation of coatings based on solventborne compositions according to the invention

[0066] A solid solvent solution of high molecular weight epoxy resin based on bisphenol A was used as an adhesive. 40 to 50% solids were obtained using 1-methoxypropyl acetate-2. Novolac type phenolic resins and modified novolak resins (epoxy equivalent weight 160 to 170 g / equivalent, epoxy functionality 2.0) are used as cross-linking agents in amounts (each based on 100 parts 100% Solid epoxy resin calculation) as shown in Table 2. Then add 1 part by weight of flow reagent BYK -310. In the final step, the nanoparticles Aerosil were added in the amount shown in Table 2. R 7200 is added to the formula. Stir the mixture until it becomes homogeneous.

[0067] The coating composition was applied to electrical steel sheets by rollers and forced dried by a PMT (maximum metal temperature) of 220 to 230°C to give an active coating with a film thickness of about 4 microns. Then, th...

Embodiment 3

[0070] Comparison with state-of-the-art electrical steel sheet coatings

[0071] The NO.7 composition according to JPH11-193475 comprises: 100 parts by weight (solid) of water-dispersible bisphenol A type epoxy resin and 15 parts by weight (solid) of phenolic formaldehyde based on the reaction product of 1 mole of bisphenol A and 7 moles of formaldehyde The resin, the content of the methanoly component (the content is higher than that of the dimethanol component) is 98.3% by weight, mixed with water and stirred to obtain a coating composition with a solid content of 20% by weight.

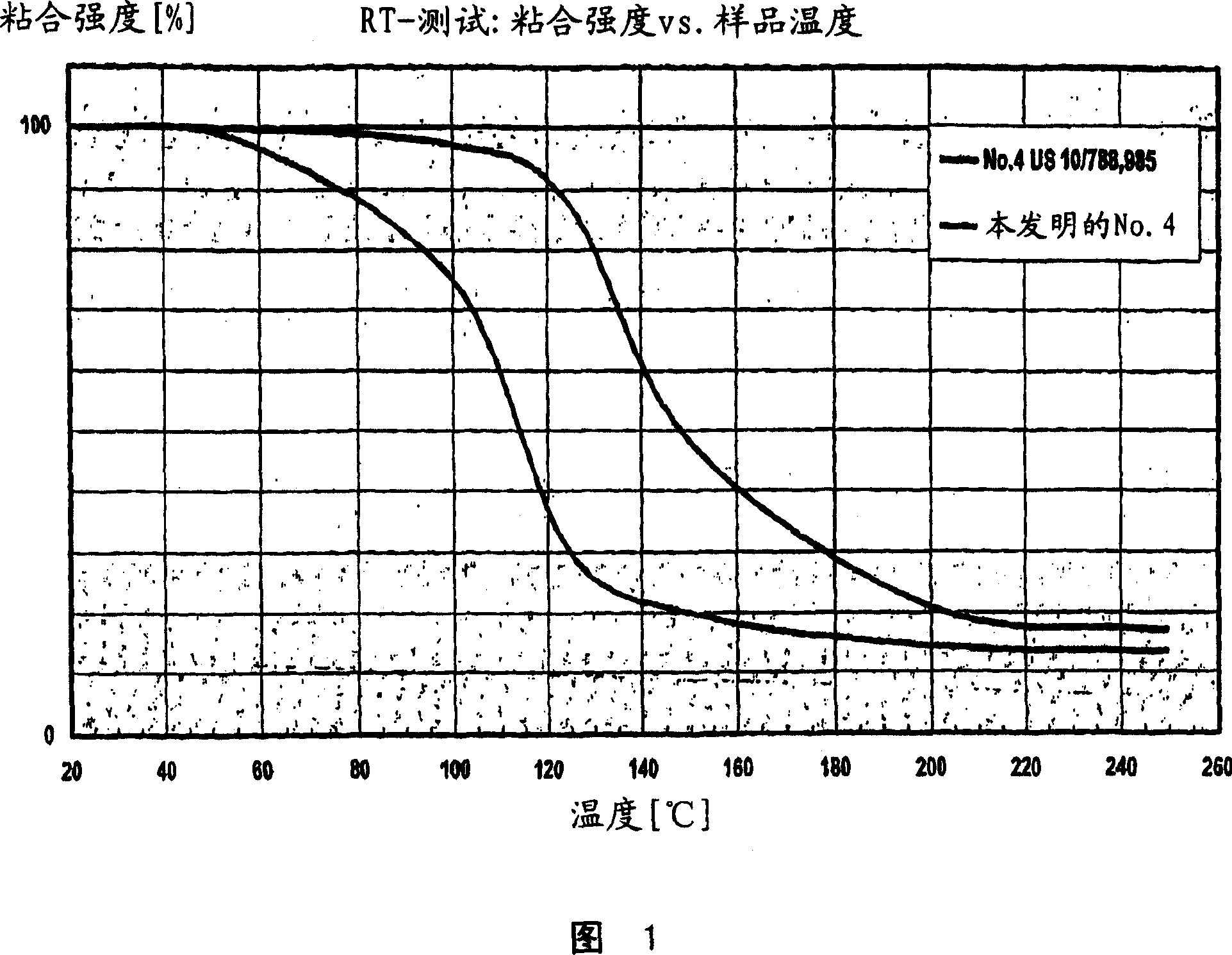

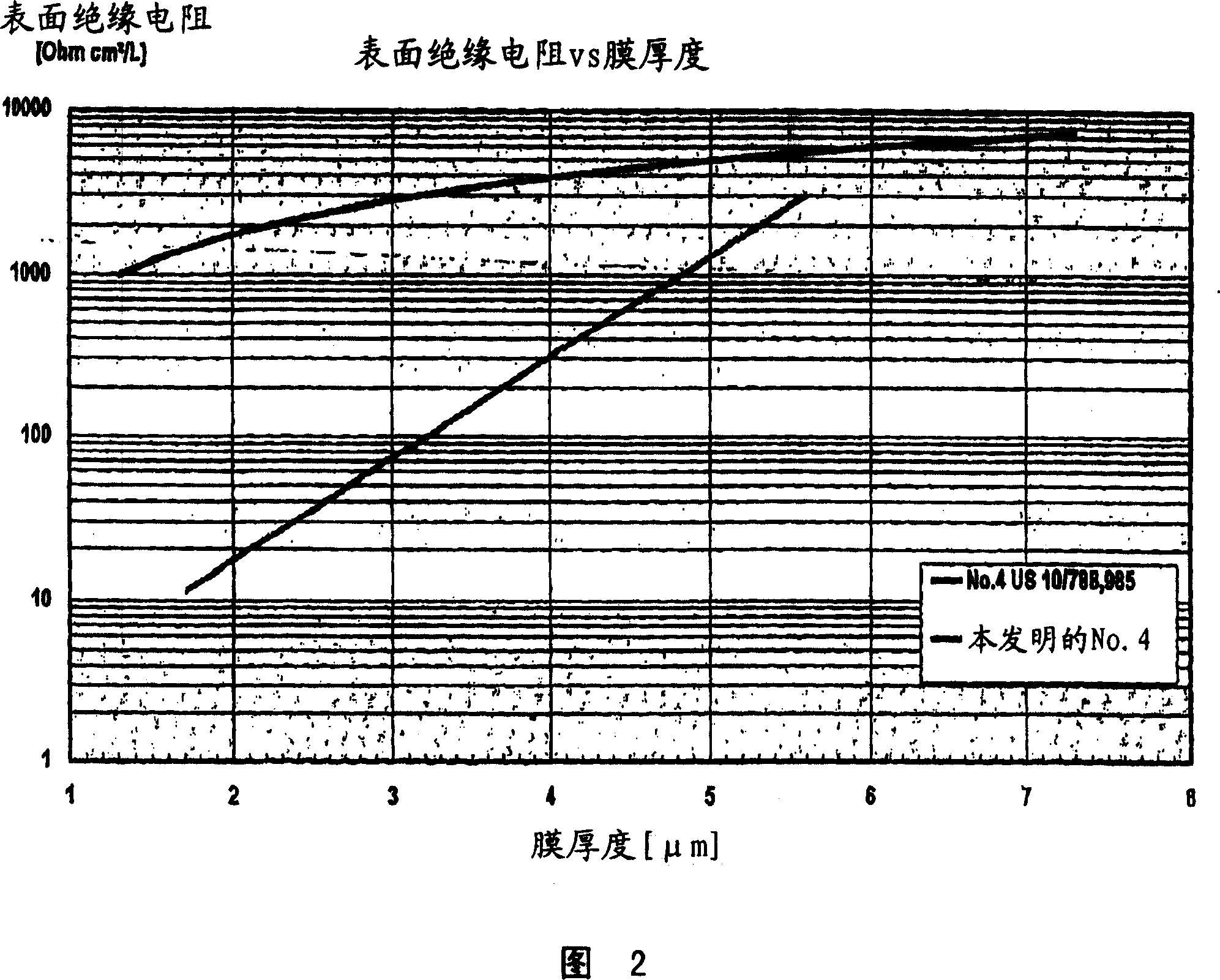

[0072] Composition No. 4 of U.S. 10 / 788985 contains the same components as composition No. 4 (comprising 5 parts by weight of dicyandiamide) in Example 1 according to the present invention, but without any nanoparticles in the composition.

[0073] The application and drying procedure and the preparation of the steel sheet cores were as described in Examples 1 and 2.

[0074] combination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com