Centrifugal fan of extractor hood

A technology of centrifugal fans and range hoods, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of polluting impellers and increasing flow losses, and achieve the effects of reducing pollution, reducing eddy currents, and improving fan performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

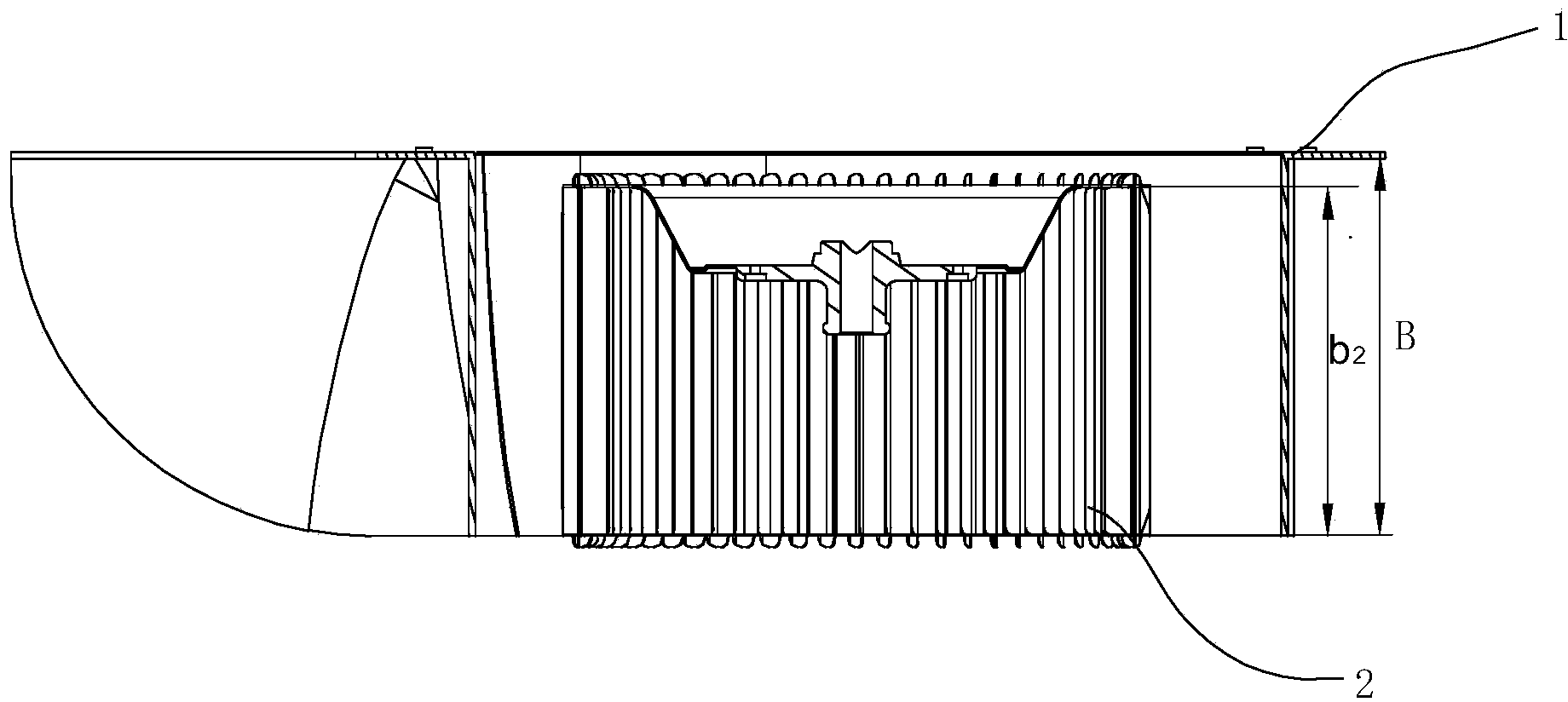

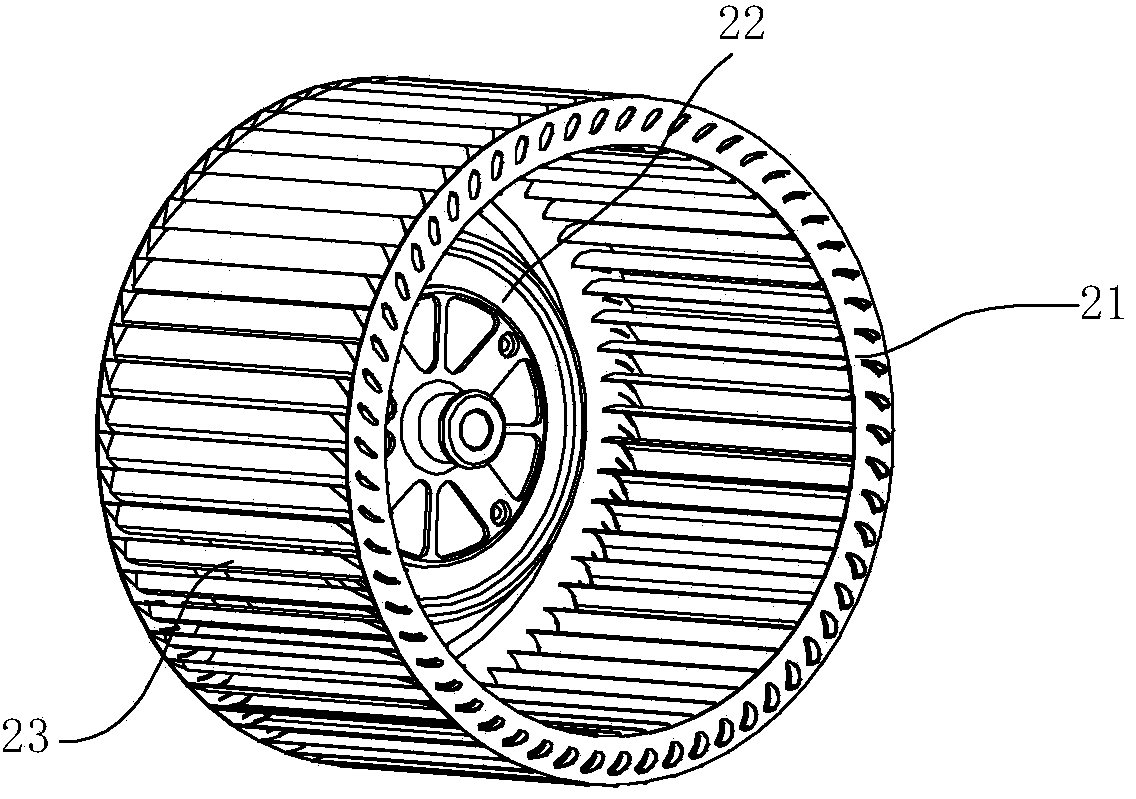

[0025] see figure 2 and image 3 , a centrifugal fan for a range hood, comprising a volute 1 and an impeller 2 arranged in the volute 1 .

[0026] The impeller 2 includes an end ring 21 , a disc 22 , and a plurality of blades 23 arranged between the end ring 21 and the disc 22 . The profile of the blade 23 is multi-diameter and multi-segment arc, which can make the air flow in the blade passage realize uniform acceleration movement, greatly reducing the flow separation or reducing the degree of flow separation in the blade passage.

[0027] see Figure 4 , the profile line C1 of the blade 23 includes two smoothly connected first circular arcs 231 at the inlet of the wind and second circular arcs 232 at the outlet of the wind, and the bending directions of the two circular arcs are consistent, wherein, R 3 is the radius of the tangent poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com