Process of detecting heat conductivity coefficient of protecting slag

A detection method and technology for mold flux, which are applied in the fields of material thermal conductivity, electrical digital data processing, special data processing applications, etc., can solve the difficulty in measuring heat flux q, the ability of mold flux to control heat transfer cannot be accurately determined, and it is difficult to accurately measure and other problems to achieve stable and normal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

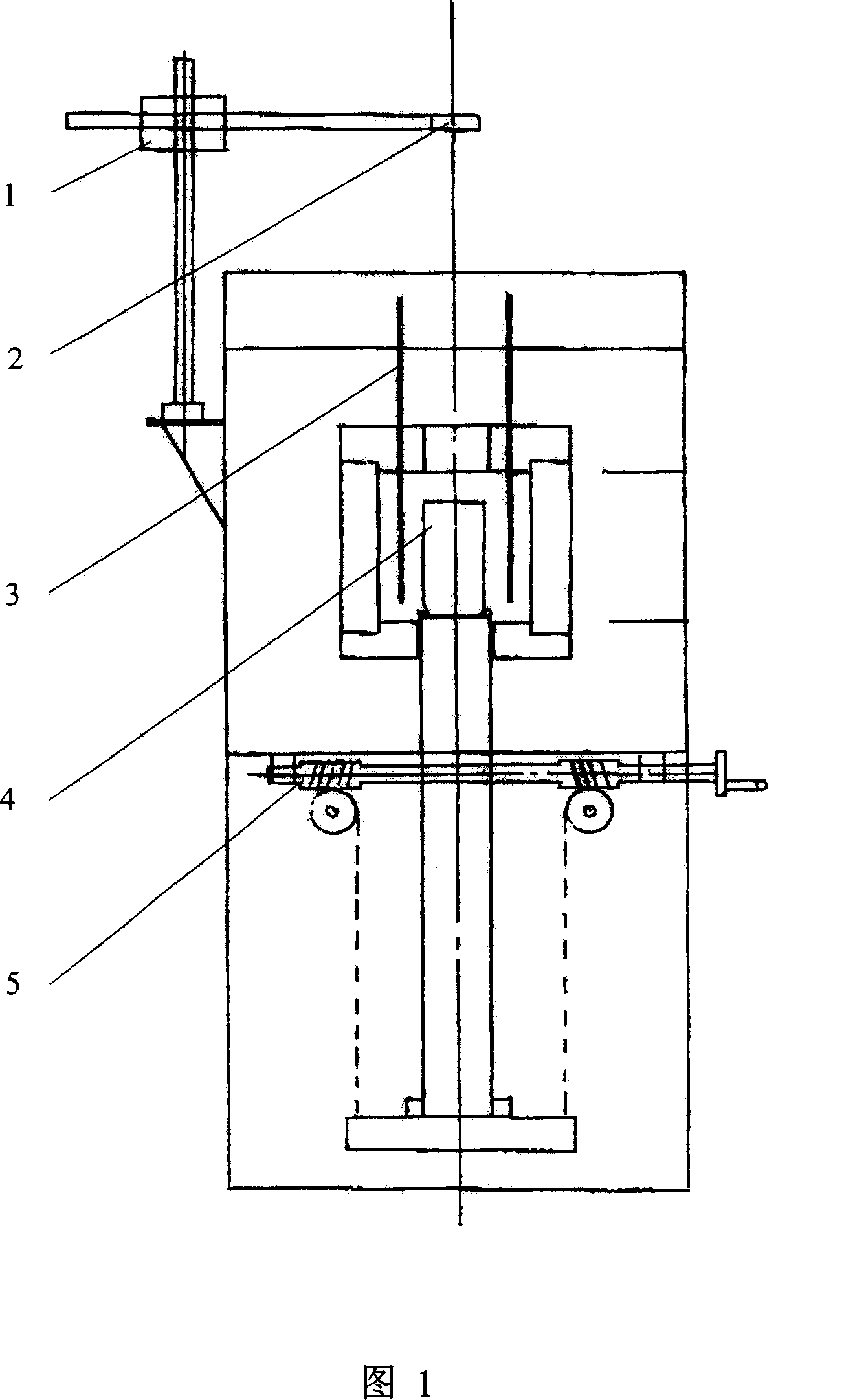

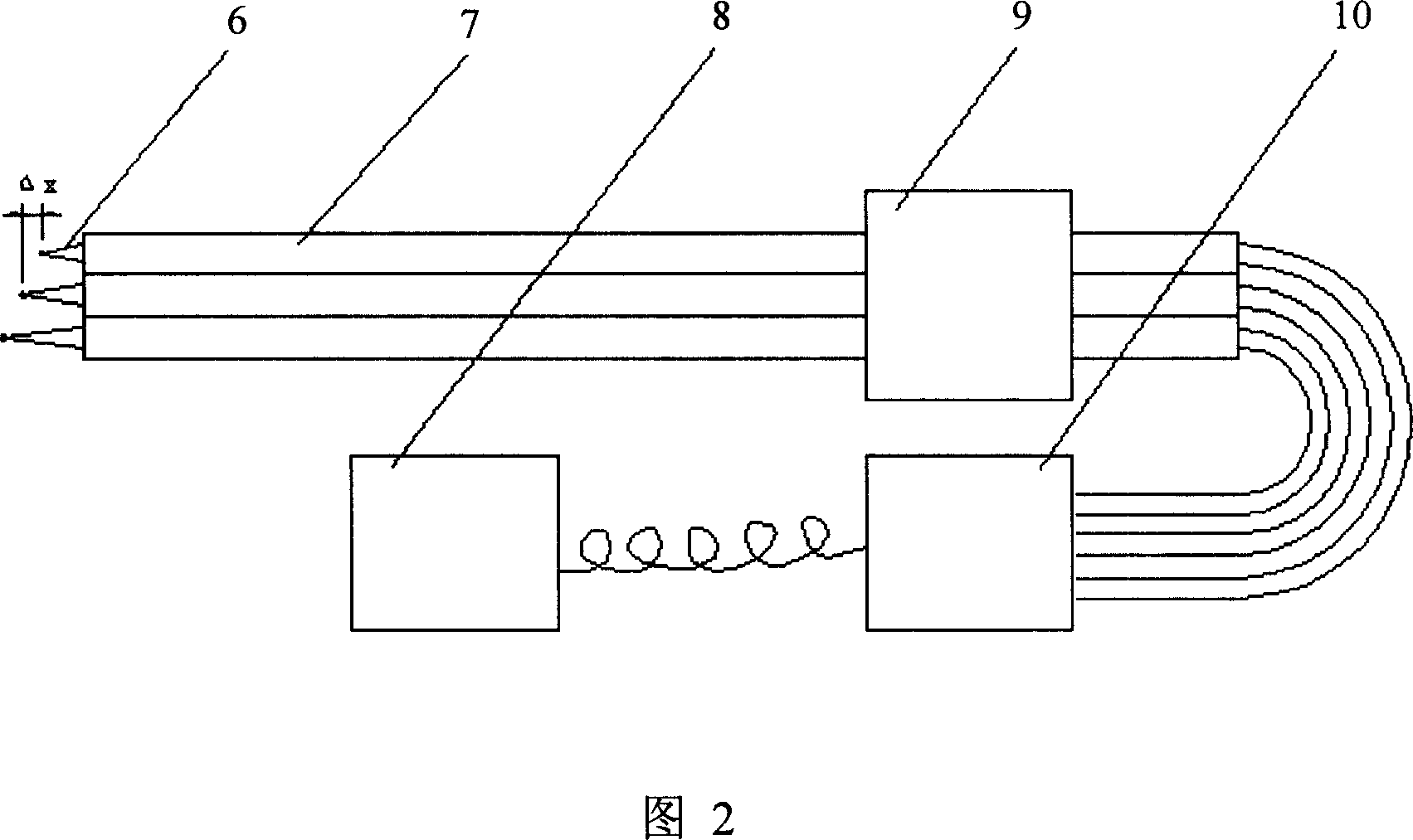

[0032] Referring to Figure 1 and Figure 2, the mold slag temperature conductivity detection device consists of three parts: a temperature control system, a thermocouple, a crucible lifting system, and a temperature acquisition system. Among them: the temperature control system adopts temperature programming, and the heating elements used are silicon carbide rods 3, six in total, and the graphite crucible 4 is used to hold the mold powder. The outer diameter of the crucible is 100mm, the inner diameter is 80mm, and the height is 100mm. The lifting system is divided into two parts: the crucible lifting system 5 and the thermocouple lifting system 1; the crucible lifting system 5 is used to push the crucible 4 filled with molten mold slag out of the furnace; the thermocouple lifting system 1 is used to lift the thermocouple for temperature measurement 6 is inserted into the liquid slag, and is controlled manually or electrically. In this embodiment, the manual mode is adopted, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com