Zirconium oxide ceramic material of ytterbium oxide and yttrium oxide costabilize

A technology of zirconia ceramics and stabilized zirconia, which is applied in the field of zirconia-based ceramic products and preparation, which can solve the problems of affecting mechanical properties and not being able to obtain TZP ceramics, so as to avoid hard agglomeration, avoid powder particle growth, and reduce dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

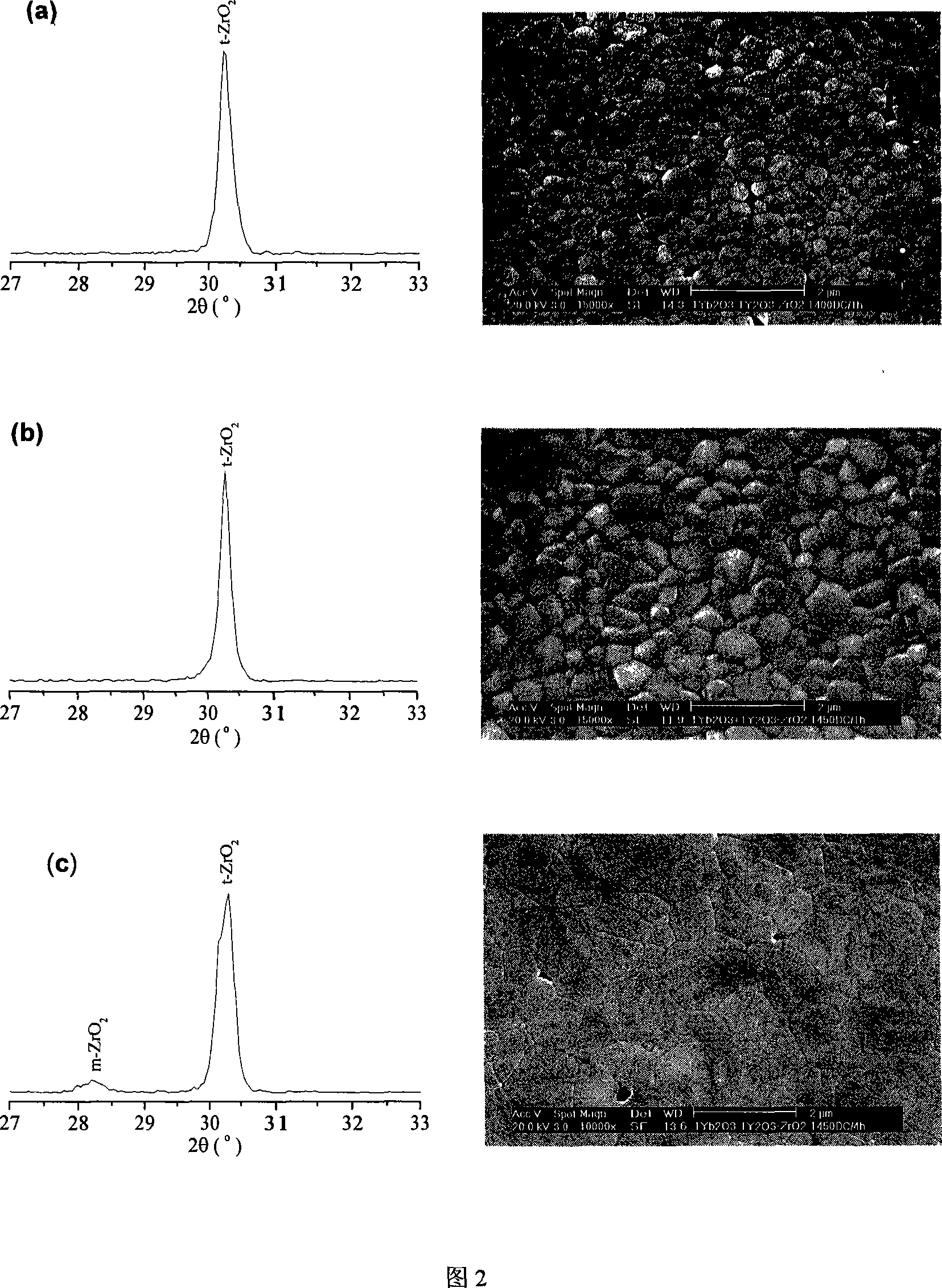

[0024] Example 1 ytterbium oxide (Yb) with a purity of not less than 99.9% 2 O 3 ), yttrium oxide (Y 2 O 3 ) And monoclinic zirconia powder (the average grain size is less than 100 nanometers) as raw materials, the design finally obtains ytterbium oxide (Yb) in TZP ceramics 2 O 3 ) The mole percentage is 1.0%, yttrium oxide (Y 2 O 3 ) The mole percentage is 1.0%. According to the above composition ratio, select the appropriate amount of the corresponding compound, and the ytterbium oxide (Yb 2 O 3 ) And yttrium oxide (Y 2 O 3 ) Dissolve in an appropriate amount of nitric acid to obtain a clear solution, use Y-TZP balls as a ball milling medium, mix with monoclinic zirconia powder with an average grain size of less than 100 nanometers in absolute ethanol and ball mill for 24 hours. After ball milling, the suspension was dried with a rotary evaporator to obtain a precursor that encapsulated the powder. The precursor was calcined in the air at 300° C. for 1 hour to obtain zirconia na...

Embodiment 2

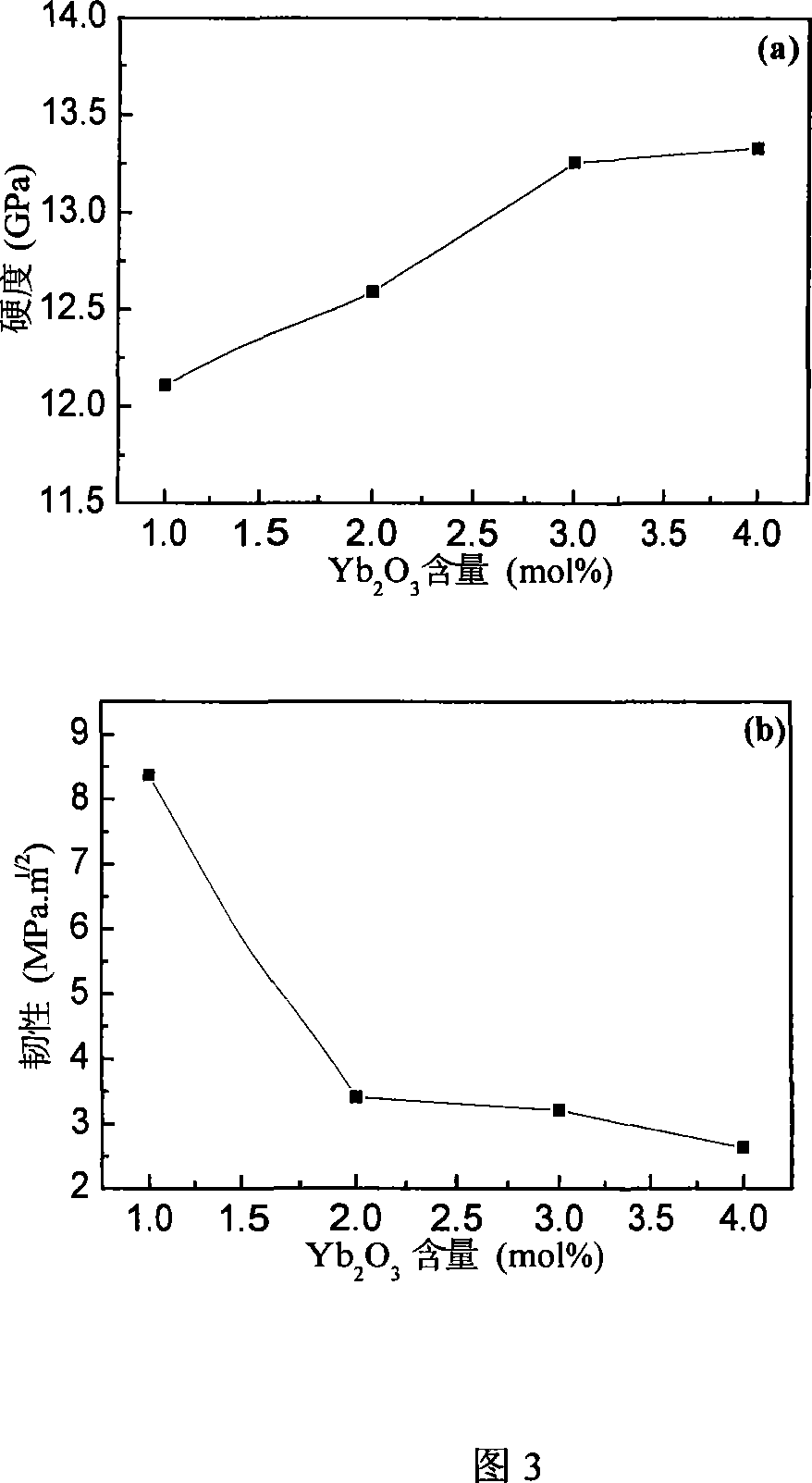

[0025] Example 2 Design and finally obtain ZrO 2 Ytterbium oxide (Yb 2 O 3 ) The mole percentage is 2.0%, yttrium oxide (Y 2 O 3 ) The mole percentage is 1.0%, the powder is synthesized according to the method of Example 1 to prepare ceramics, and the sintering time is 1 hour. Prepared ZrO 2 The mechanical properties of ceramics are shown in Figure 3.

Embodiment 3

[0026] Example 3 Design and finally obtain ZrO 2 Ytterbium oxide (Yb 2 O 3 ) The mole percentage is 3.0%, yttrium oxide (Y 2 O 3 ) The mole percentage is 1.0%, the powder is synthesized according to the method of Example 1 to prepare ceramics, and the sintering time is 1 hour. Prepared ZrO 2 The mechanical properties of ceramics are shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com