Omnidirectional visual sensor based helmet

An all-round vision and sensor technology, applied to helmets, helmet covers, closed-circuit television systems, etc., can solve the problems of poor real-time performance and only obtain images from the front view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

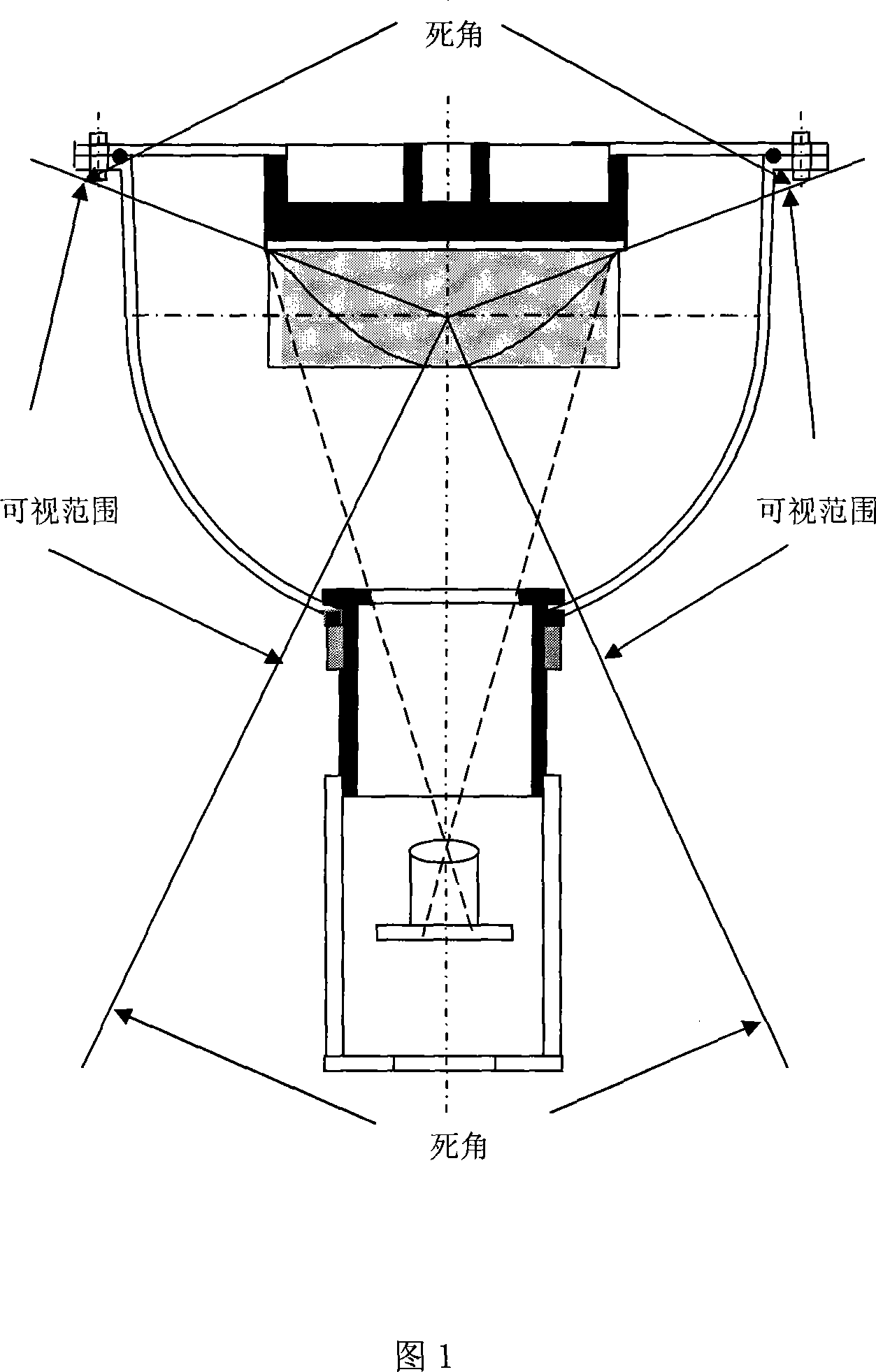

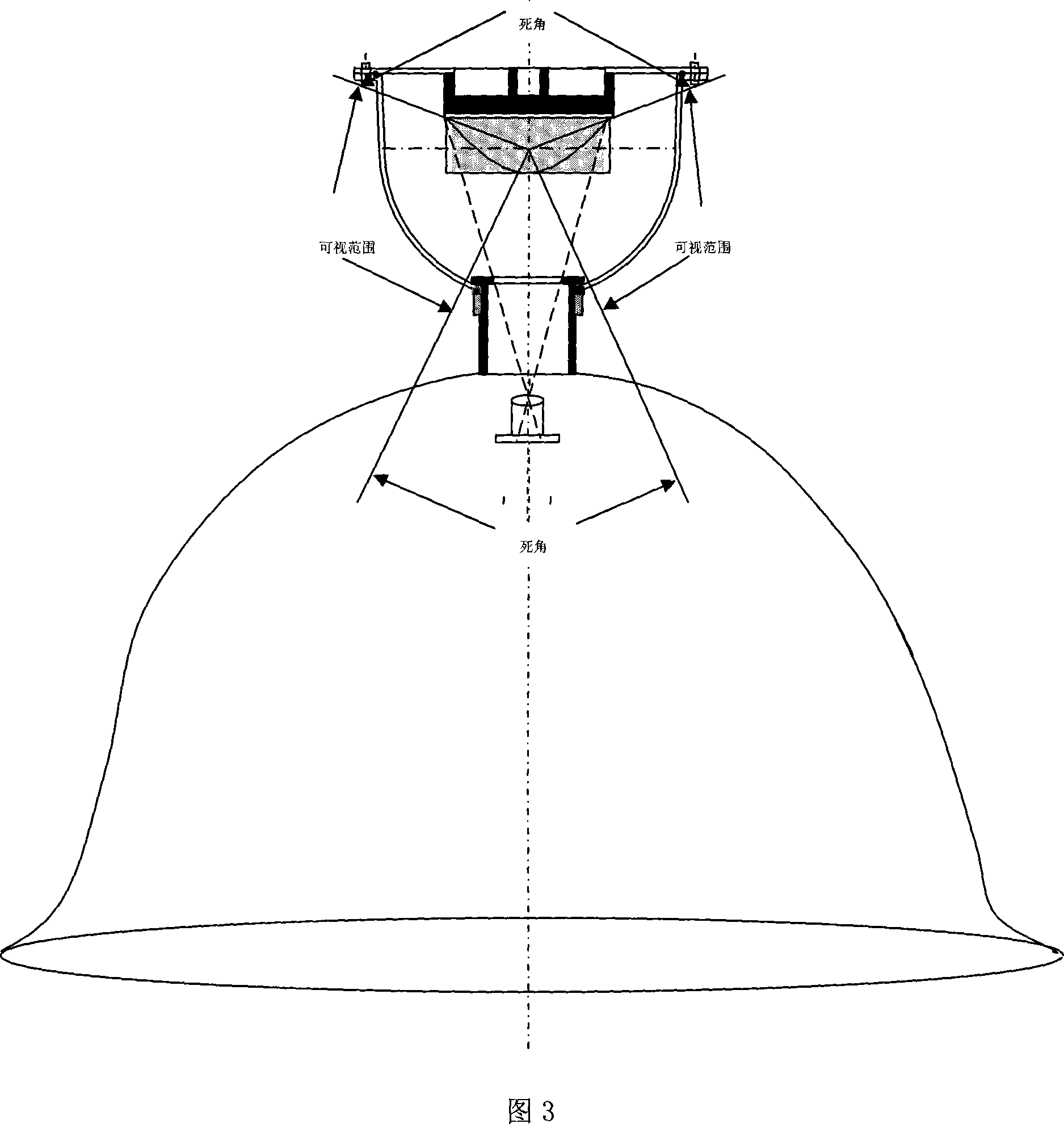

[0048] Referring to Figures 1 to 8, a helmet based on an omnidirectional visual sensor, the helmet mainly performs two functions, the first is to obtain the omnidirectional image of the scene in real time; the second is to realize the wireless remote transmission of the omnidirectional image.

[0049] The real-time acquisition of the omnidirectional image of the scene is realized by the omnidirectional visual sensor, so firstly it is the manufacturing technical scheme of the optical part of the omnidirectional visual sensor (ODVS camera device), the omnidirectional visual sensor includes a vertically downward folding reflector, transparent cylinder, camera, fixed bracket, the catadioptric mirror is a hyperboloid mirror, the camera includes a condenser lens and a camera unit, and the camera unit is located at the virtual focus of the hyperboloid mirror position; the optical system formed by the hyperboloid mirror is represented by the following 5 equations;

[0050] ((X 2 +Y ...

Embodiment 2

[0080] Referring to FIG. 1 to FIG. 9 , except for the wireless communication technology, the others are the same as the first embodiment. The wireless local area network communication technology in Embodiment 1 is applicable within the range of 100-200 meters, for example, wireless communication can be realized between the helmet and the fire engine. Need farther distance to realize wireless communication in some occasions, therefore set up a GPRS server at the video server end in the helmet among the present invention, set up a kind of high-speed CDMA wireless communication network that is suitable in small area. In the present invention, each helmet capable of wireless remote transmission of omnidirectional images is used as a wireless network terminal, as shown in 1 in Fig. 9, wherein the high-speed CDMA wireless communication network includes at least one CDMA base station (shown in 2 in Fig. 9) and several A wireless network terminal (helmet) in its coverage area is chara...

Embodiment 3

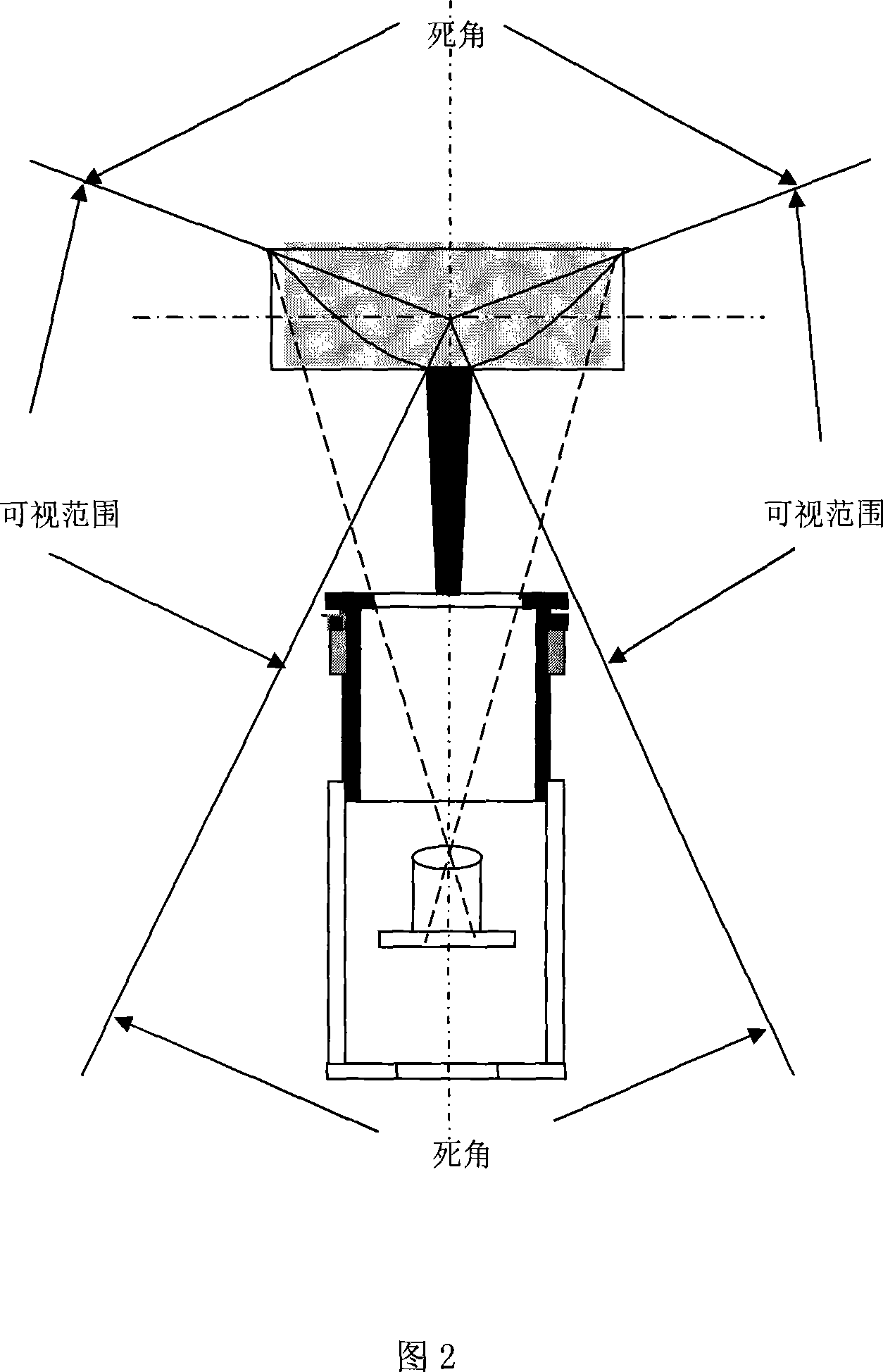

[0084] Except for the manufacturing technology of the omnidirectional vision sensor, the others are the same as the embodiment 1. The manufacturing material of the omnidirectional vision sensor in embodiment 1 basically adopts the material that can be used under the non-high temperature situation, for the special circumstances such as fire-fighting helmet, the manufacturing material of the omnidirectional vision sensor must adopt the material of high temperature resistance, so for For the helmet used for fire fighting, due to the high temperature at the fire scene, the transparent cover 2 will be deformed and damaged. The fixing bracket and the catadioptric mirror are connected by a metal rod. The centers of the metal rod, fixing bracket, and catadioptric mirror are all in one center. On the axis, as long as the thickness of the metal rod does not hinder the panoramic image, the structure of the ODVS without a cover is shown in Figure 2; of course, the catadioptric mirror must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com