Two-step flexible top end dilater and the method for preparing the same

A manufacturing method and technology of dilators, applied in the field of medical devices, can solve the problems of falling off of flexible tips and reducing product safety, and achieve the effect of ensuring pushing force, strong flexibility and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

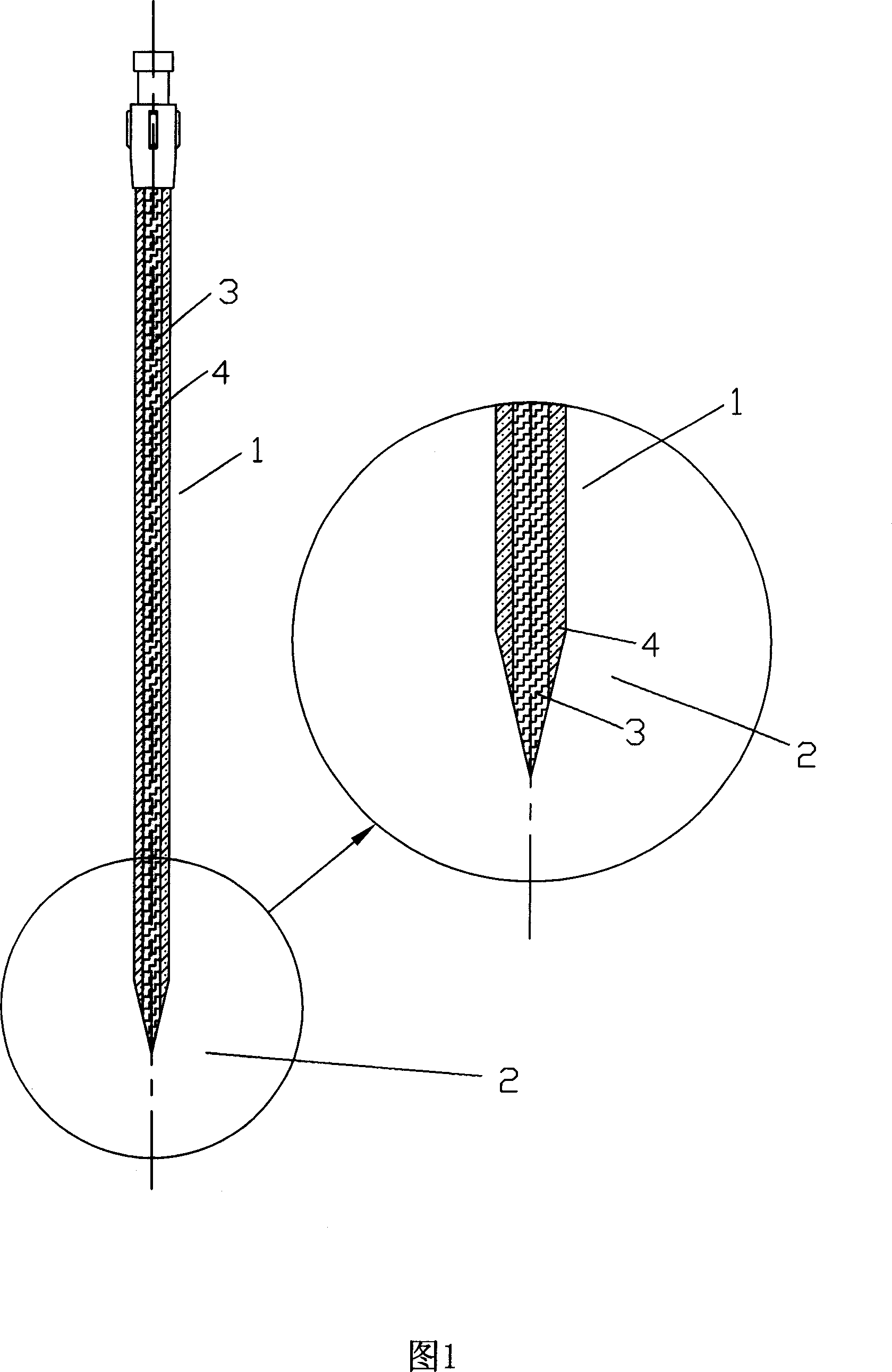

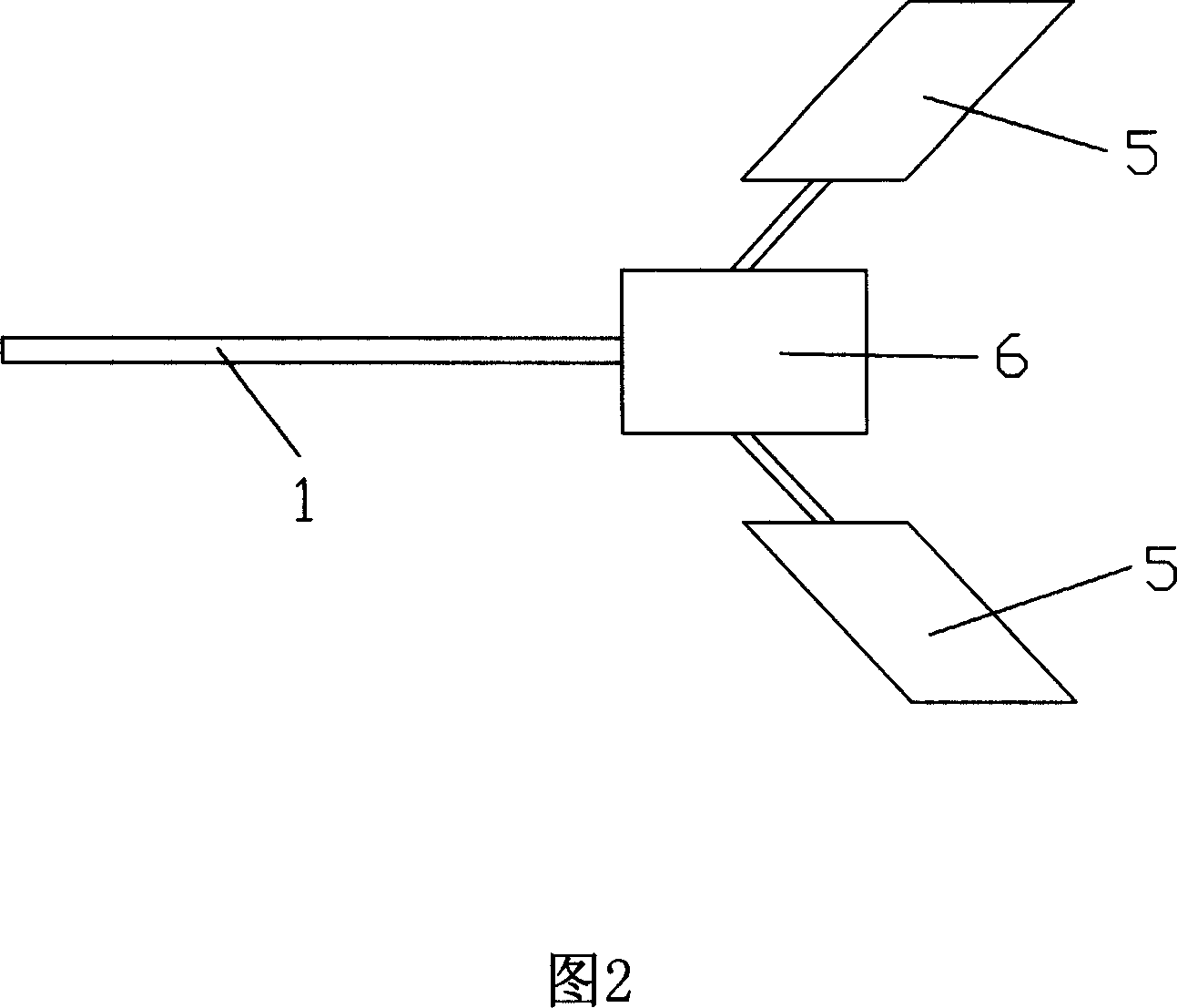

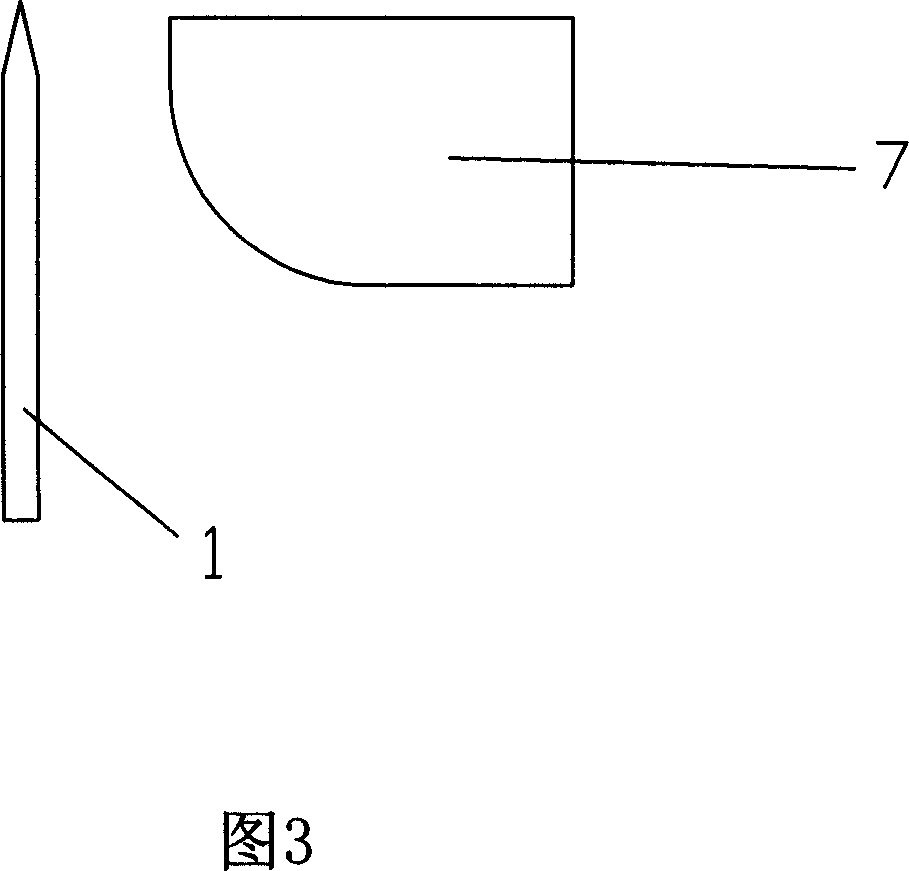

[0025] The structure of the double-stage flexible tip dilator of the present invention includes a tube body (1) and a tip (2), and different rigid materials are layered to form the tube body (1) and tip (2) of a slender coreless tube. The segmental connection of different rigid materials in the prior art is changed to a layered connection. This innovation fundamentally solves the problem of welding or bonding flexible tips on rigid materials in existing products, which may cause the flexible tips to fall off and cause The problem of clinical safety incidents. The tube body (1) and the tip (2) formed by layers of materials with different rigidities are integrally formed integral structures.

[0026] In the double-stage flexible tip dilator of the present invention, the materials with different rigidities are layered and thermally fused.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com