New technique for producing automobile gas by using marsh gas

A new technology, biogas technology, applied in the direction of gas fuel, fuel, petroleum industry, etc., can solve the problems of difficult promotion of dual-gas fuel vehicles, limited number of natural gas filling stations, and queuing up of vehicles for refilling, etc., to achieve a small footprint , small investment, prolonging the effect of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For a better description of the process, examples are given as follows:

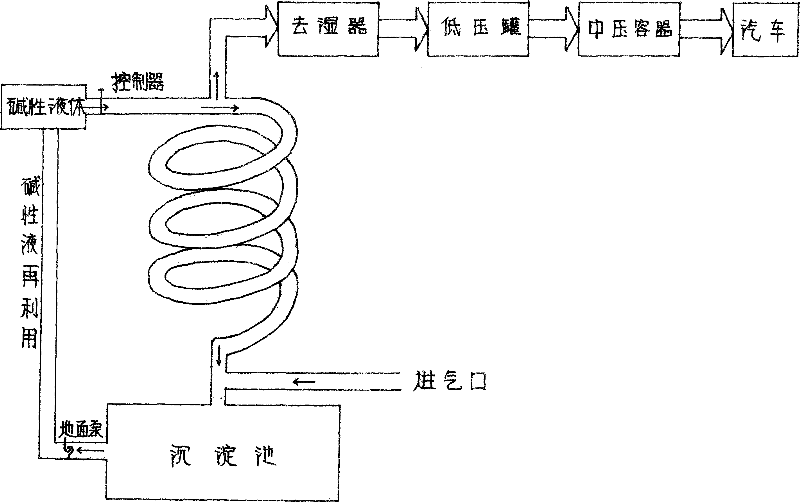

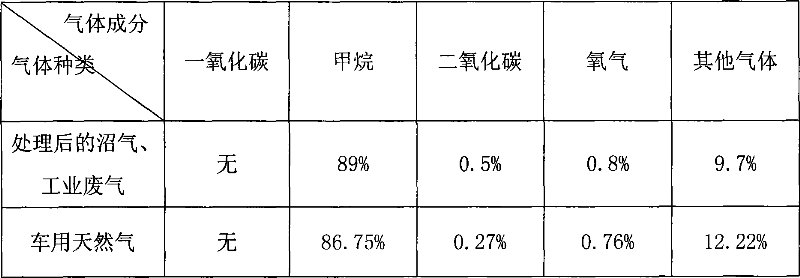

[0018] Biogas energy can be obtained from agricultural organic waste, human and animal manure, industrial organic wastewater and waste, urban underground sewer sewage, sludge fermentation treatment, and urban garbage dumping fermentation. In the present invention, the obtained biogas enters the biogas purification system of the present invention through the biogas collection system and the biogas delivery system. 2 、H 2 S is fully contacted and reacted with the alkaline liquid and absorbed by the alkaline liquid. At this time, the alkaline liquid is continuously injected into the spiral tube at a uniform speed by adjusting the valve of the alkaline liquid storage tank to keep the concentration of the alkaline liquid stable; at the same time The alkaline liquid in the spiral tube is discharged from the lower discharge port at a certain speed, and after the discharged alkaline liquid is settled, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com