Method for preparing carbon nano tube including Ethylenediamine double-injection

A technology of carbon nanotubes and ethylenediamine, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effect of increasing binding force and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

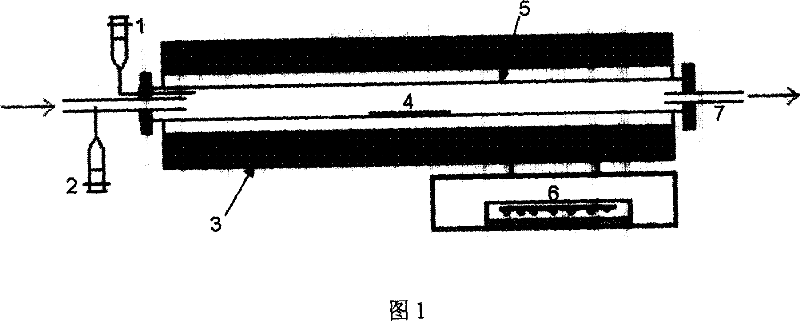

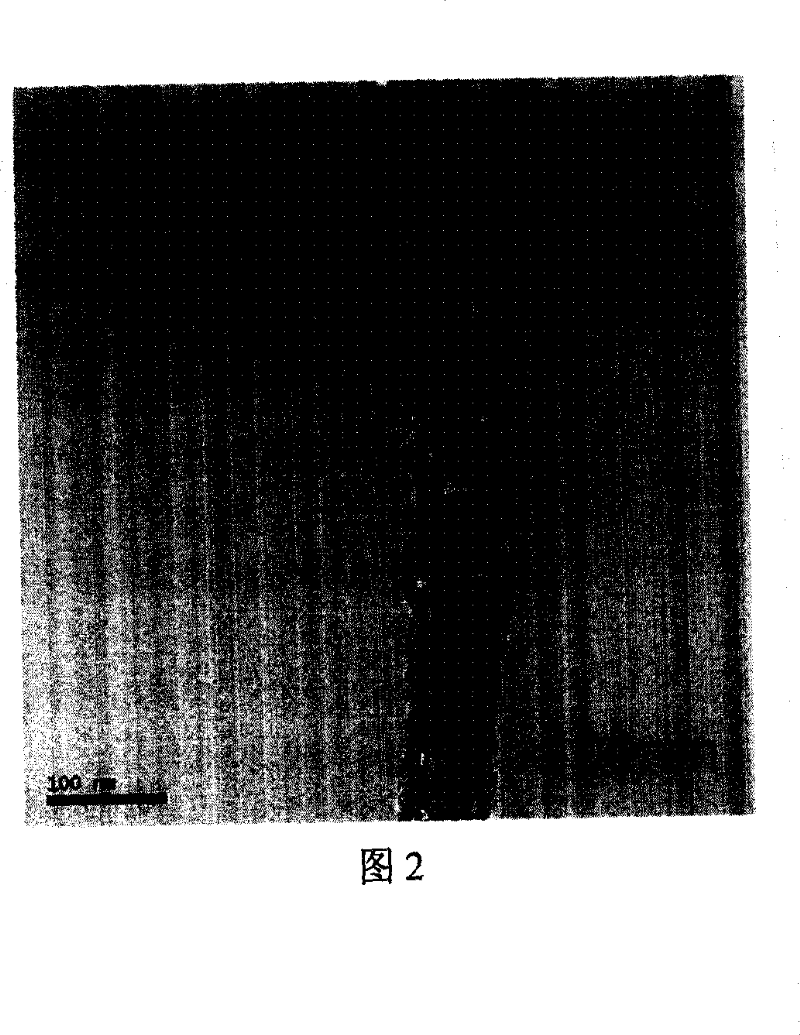

[0021] Ferrocene methanol saturated solution and ethylenediamine are used as raw materials, and 1000ml / min argon is used as carrier gas. Using syringe 1 driven by a micro-injection pump, a saturated solution of ferrocenemethanol was introduced into a quartz tube reactor equipped with a quartz plate at an injection rate of 10ml / h, and at the same time, using syringe 2 driven by a micro-injection pump, ethylenediamine Inject 2.5ml / h into a quartz tube reactor and react at 900°C for 40min to prepare bamboo carbon nanotubes.

example 2

[0023] The experimental conditions and process were the same as in Example 1, but the reaction temperature was changed to 850° C. to prepare bamboo carbon nanotubes.

example 3

[0025] The experimental conditions and process were the same as in Example 1, but the reaction temperature was changed to 800° C. to prepare bamboo carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com