Liquid bearing pier structure

A liquid and new technology, applied in infrastructure engineering, bridges, bridge parts, etc., can solve the problems of complex construction, can not directly reflect the load effect, and consume a lot of manpower and material resources, to ensure construction quality, convenient factory processing, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

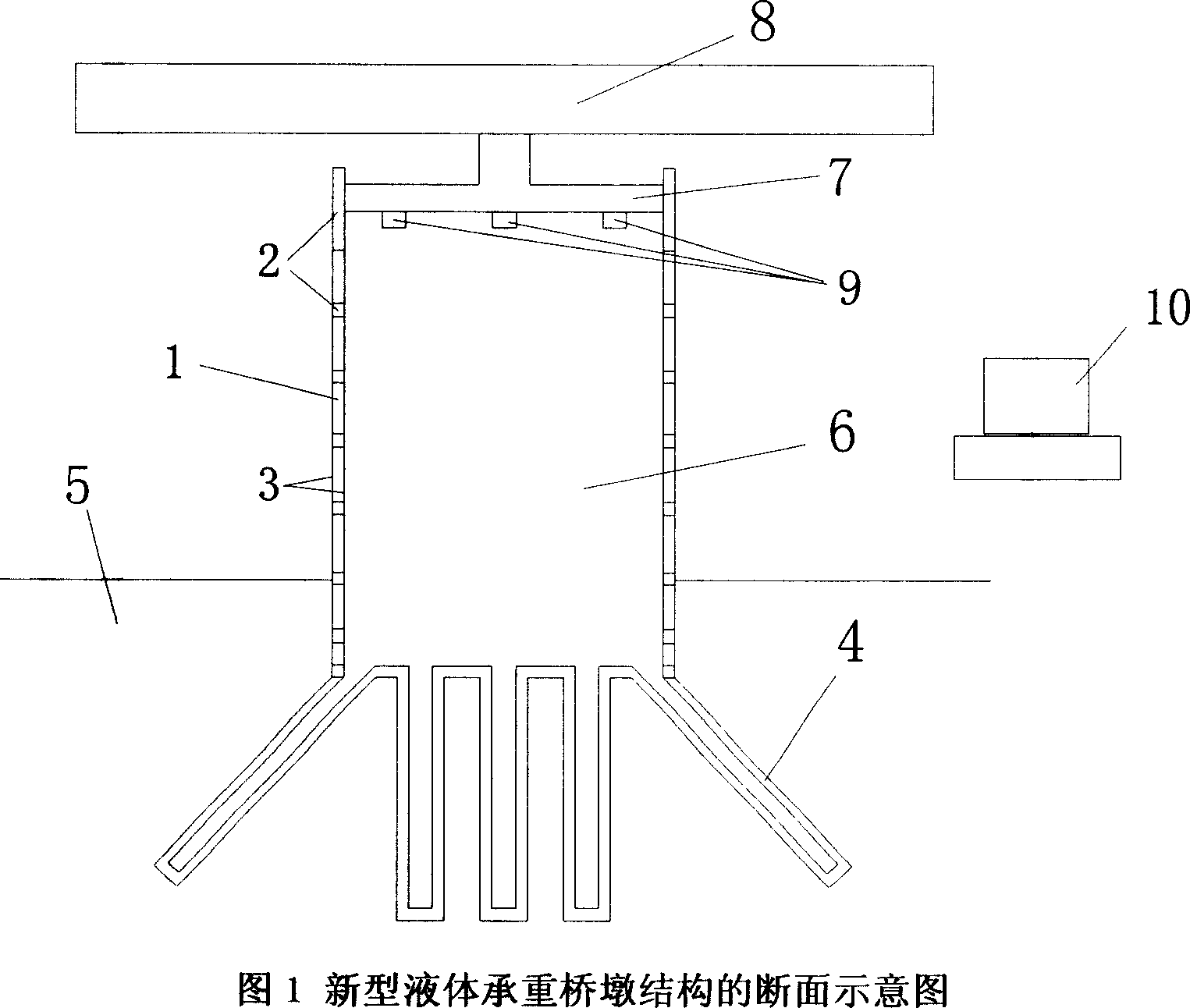

[0022] According to the designed shape and size of the bridge pier, the frame 2 of the enclosure structure 1 is made of metal materials, and then covered with a membrane 3 with waterproof and certain tensile capabilities to form a complete enclosure structure 1.

[0023] The same method of adding a metal frame to a film is used to make a root-like foundation 4. The foundation 4 is embedded in the soil body 5.

[0024] The foundation 4 can also be made by pouring conventional reinforced concrete materials.

[0025] Then, the liquid 6 is injected into the enclosure structure 1.

[0026] A support 7 is installed inside the enclosure 1 and above the liquid 6. The upper surface of the support 7 is connected with the upper structure 8 of the bridge, and the lower surface is in close contact with the liquid 6 and the liquid 6 is sealed in the enclosure structure 1. A pressure sensor 9 capable of monitoring the pressure data of the liquid 6 in real time is installed on the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com