Vacuum inner film coating machine and using method thereof

A coating machine and vacuum technology, applied in the field of vacuum internal coating machine, can solve the problems of high machine cost, long working cycle, low production efficiency, etc., and achieve the effect of convenient equipment maintenance, high production efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

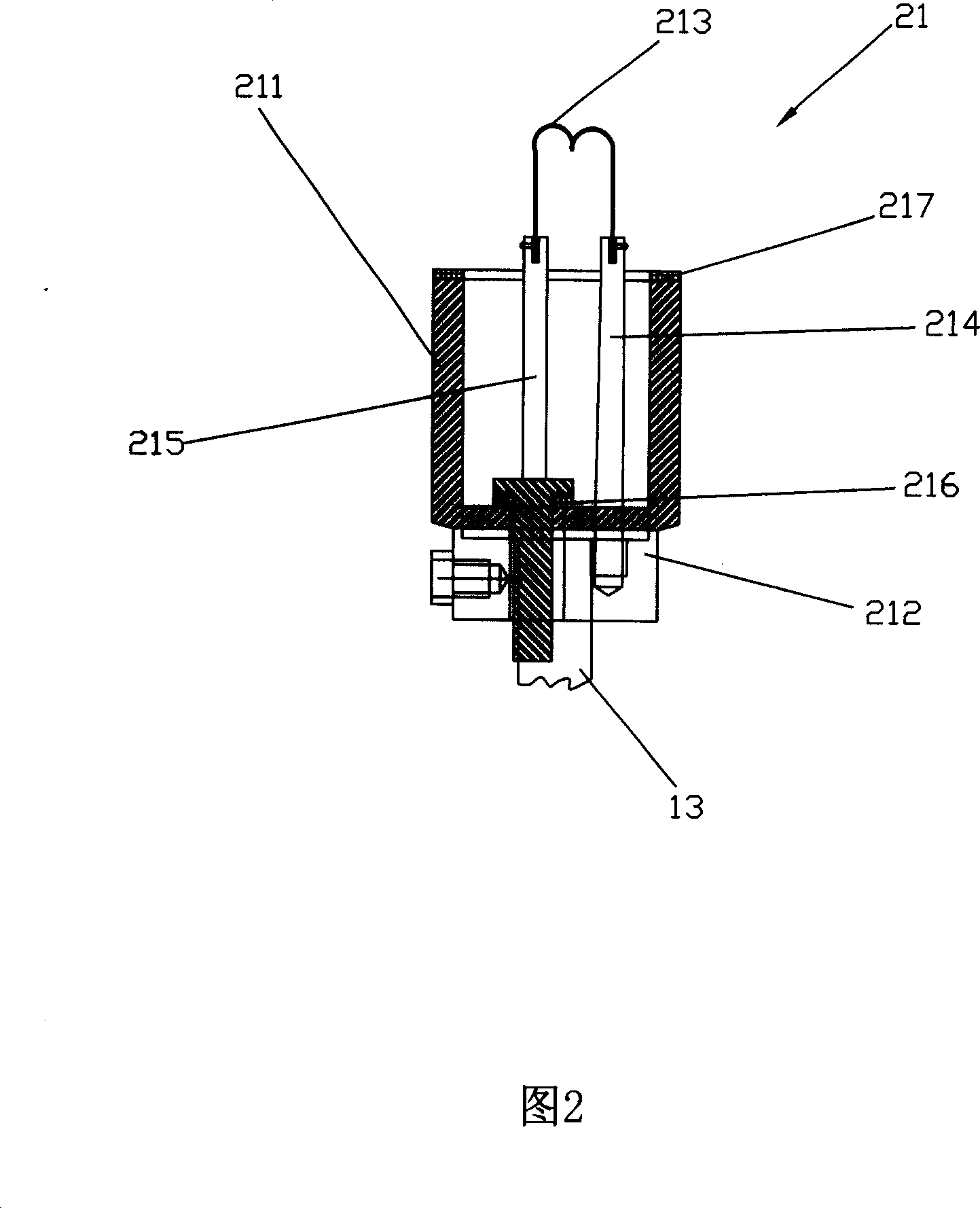

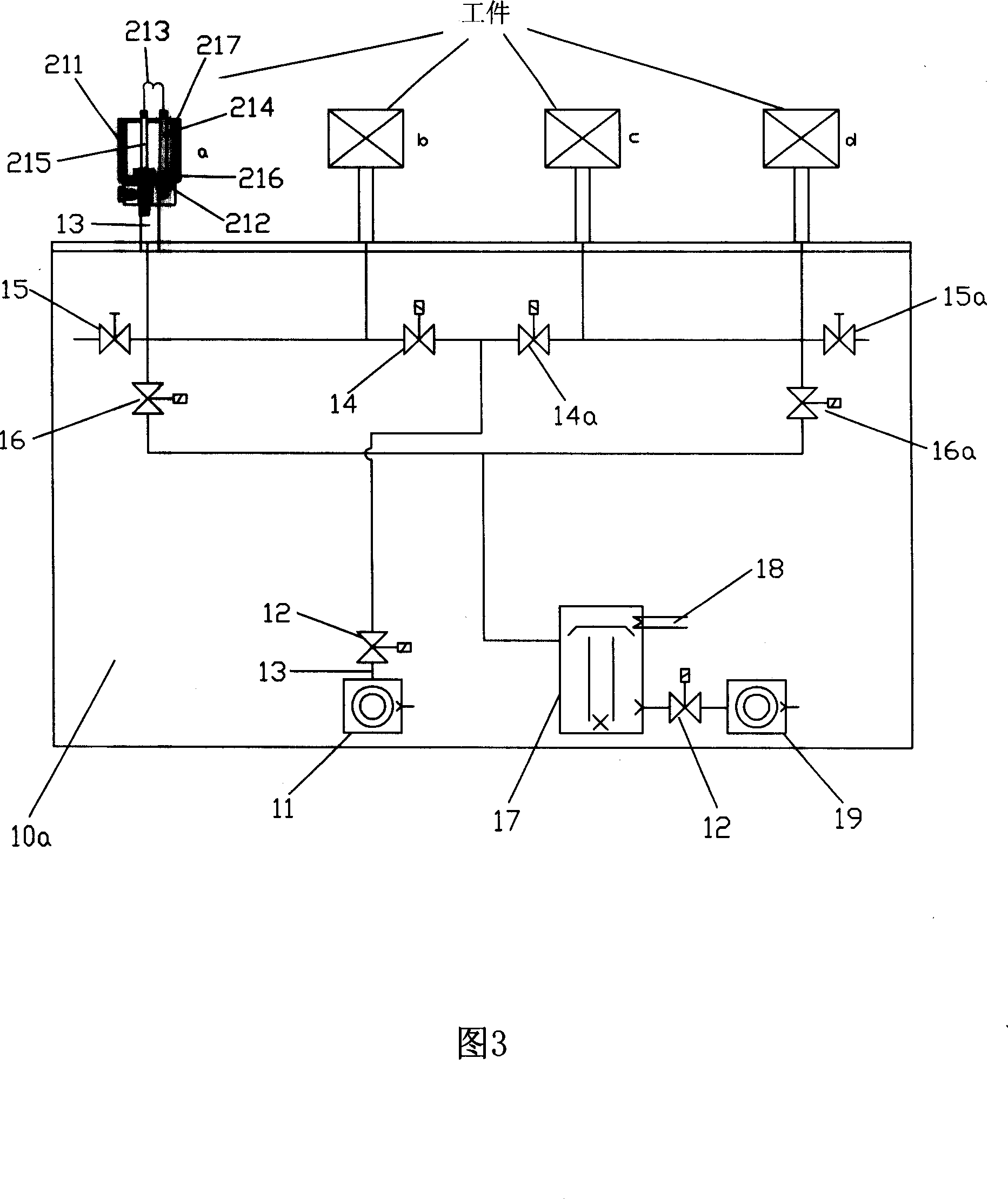

[0059] Implementation principle of embodiment two: products a and b are a group, and the high-vacuum butterfly valve (14) of the rough pumping effect is exhausted to 10 × 10 by the mechanical pump (11) earlier. -0 Pa, then close the high-vacuum butterfly valve (14), open the high-vacuum electromagnetic valve (16) of fine pumping effect to be pumped by the direct-connected mechanical pump (19); simultaneously open the high-vacuum butterfly valve (14a) of product c and d, when the product The air pressure in a and b drops to 5×10 -2 At Pa, turn on the power switch (22), energize the tungsten wire (213) of the evaporation system (20) of the products a and b, and start evaporation. After the vapor deposition is completed, close the high vacuum solenoid valve (16), open the inflation valve (15), and take off the products a and b that have completed the inner coating process; then switch the valve, close the high vacuum butterfly valve (14a), and open the high vacuum valve Vacuum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com