Salinized-soil-strong tamping and water-discharging pile foundation processing method

A foundation treatment and drainage pile technology, which is applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve the problems of difficult drainage of groundwater, low strength, poor treatment effect of saline soil, etc., and achieve cost savings in foundation treatment , Avoid secondary feeding and save construction and development funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

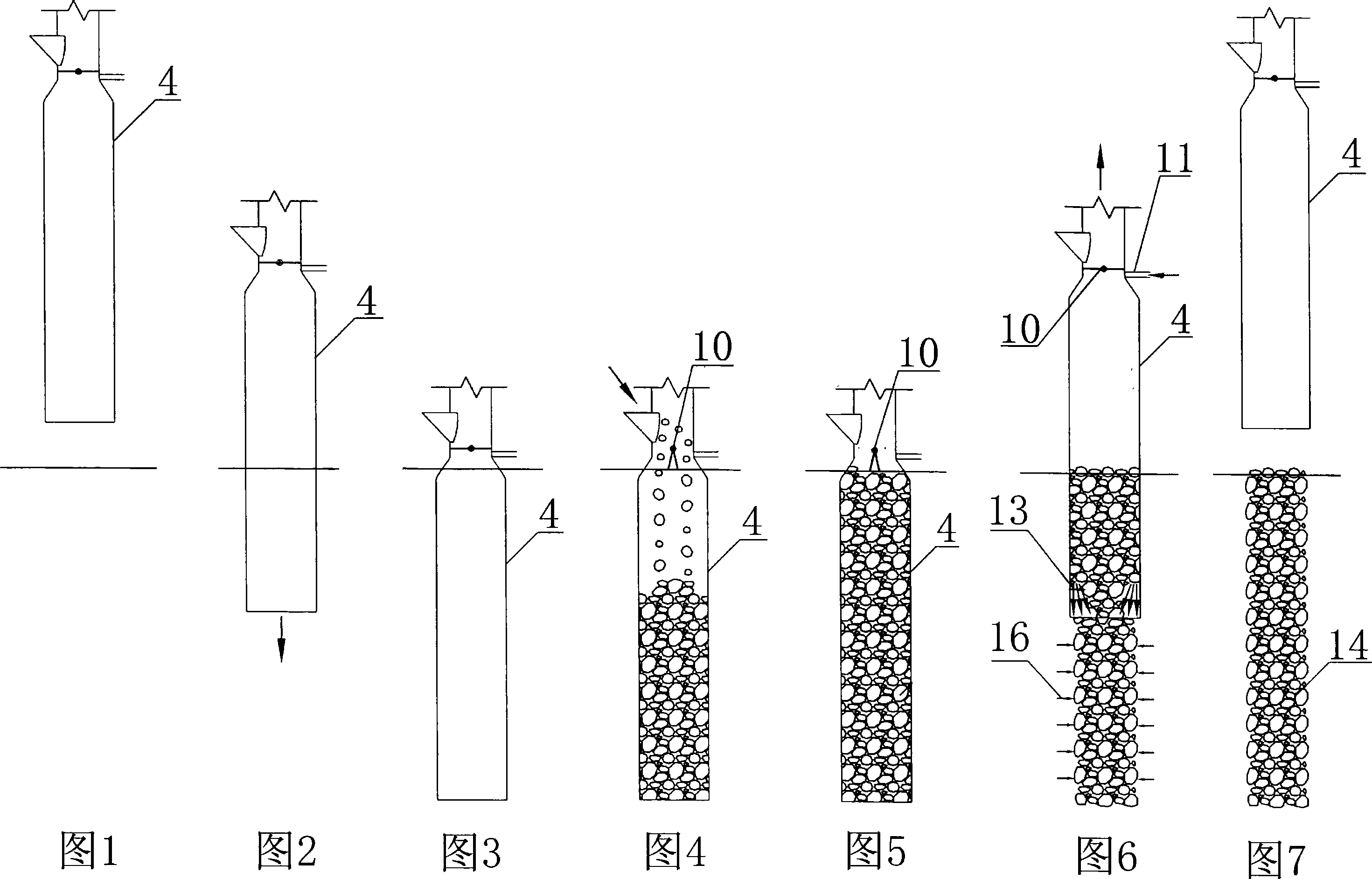

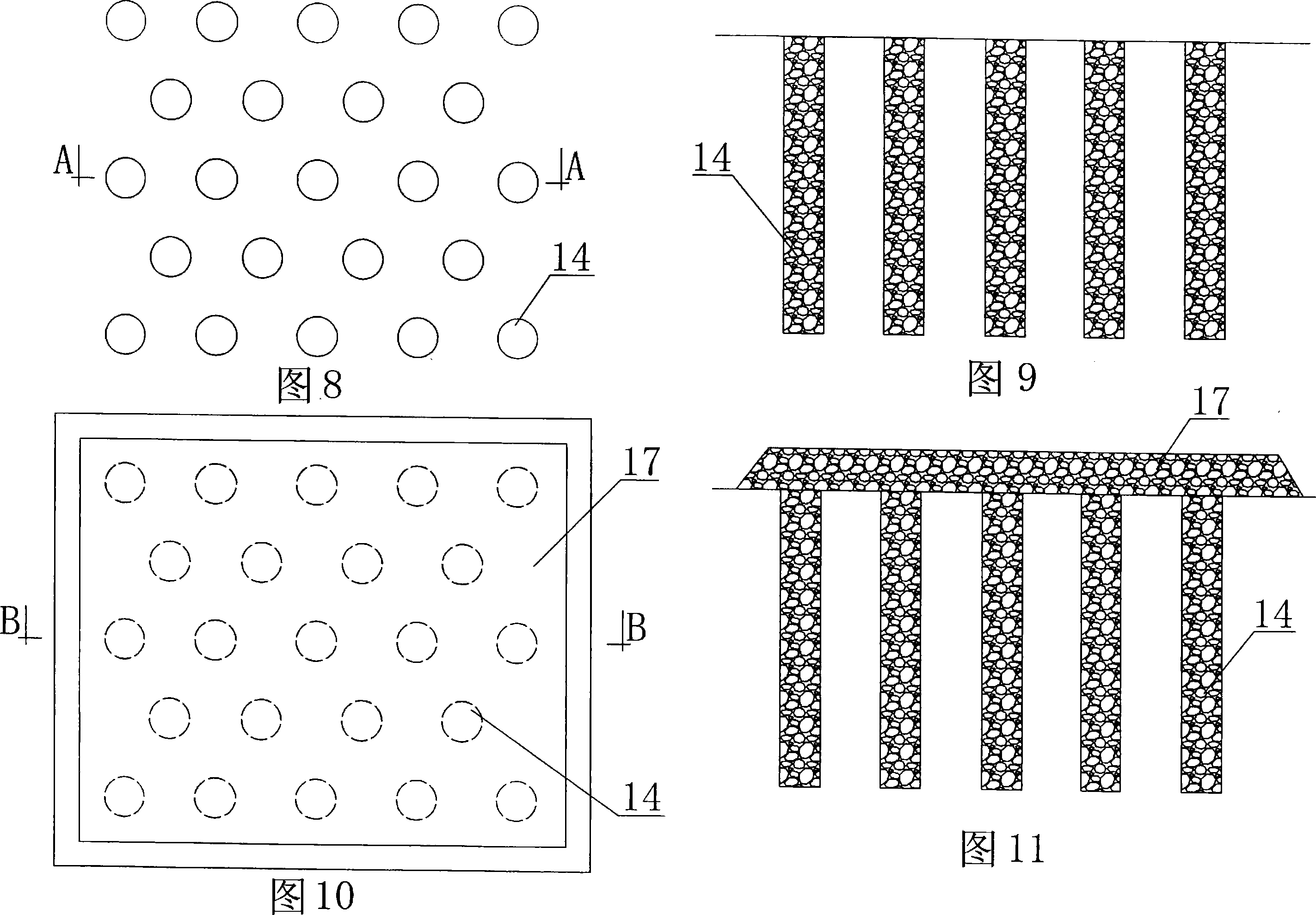

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 Referring to Fig. 17, the pile tube 4 is a bottle-shaped variable-diameter pile tube with a small diameter at the top and a large bottom. The diameter of the thin neck of the above-mentioned variable-diameter pile tube is 400mm, and the diameter of the main body of the variable-diameter pile tube is 500-550mm. The high-pressure air pipe connects the air supply pipe 12 in the pile pipe through the air inlet 11, and the air supply pipe is downward along the pile pipe inwall, and the air outlet 13 is positioned at the pile pipe lower end. One-way valve 10 is installed below the pile pipe feed inlet, and one-way valve is opened when feeding, and closed during pneumatic feeding. The diameter of the above-mentioned pile pipe is slightly larger than the designed pile diameter. The pile tube lower end discharge port of the above-mentioned vibrating tube sinking wind pile machine is connected with a built-in pile shoe 51, which is built in the pile tube by 2 or more...

Embodiment 2

[0073] Embodiment 2 Referring to Fig. 20, the above-mentioned air supply pipe 12 is an external air supply steel pipe close to the outer wall of the pile pipe. The air outlet is distributed on the inner wall of the pile pipe, and can be equipped with a one-way air outlet valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com