Semiconductor structure of liquid crystal display and producing method thereof

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve problems such as doping of polysilicon layer 124, poor display effect of displays, and inability to effectively improve storage capacitance. , to achieve the effect of increasing storage capacity, better screen display effect, and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

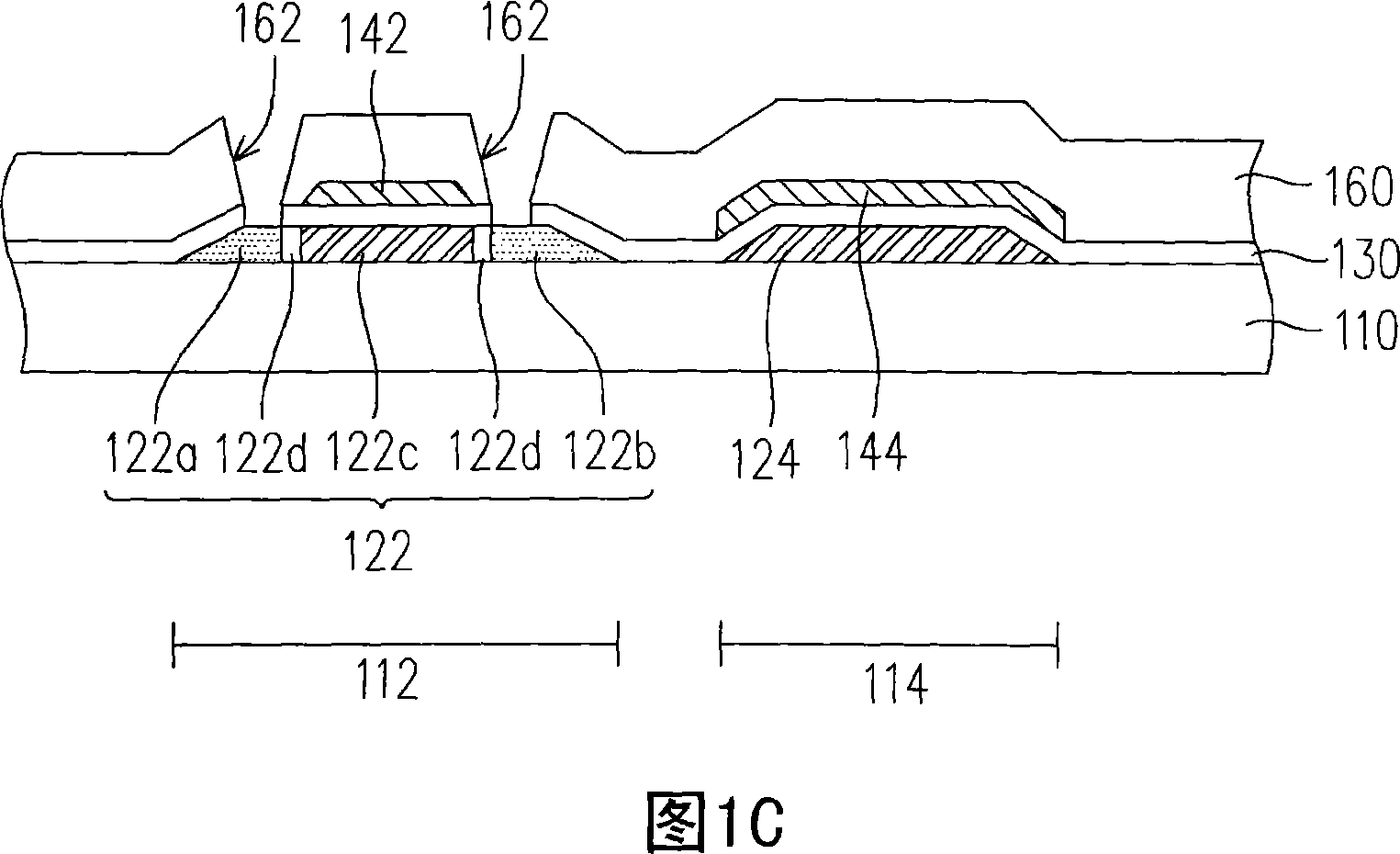

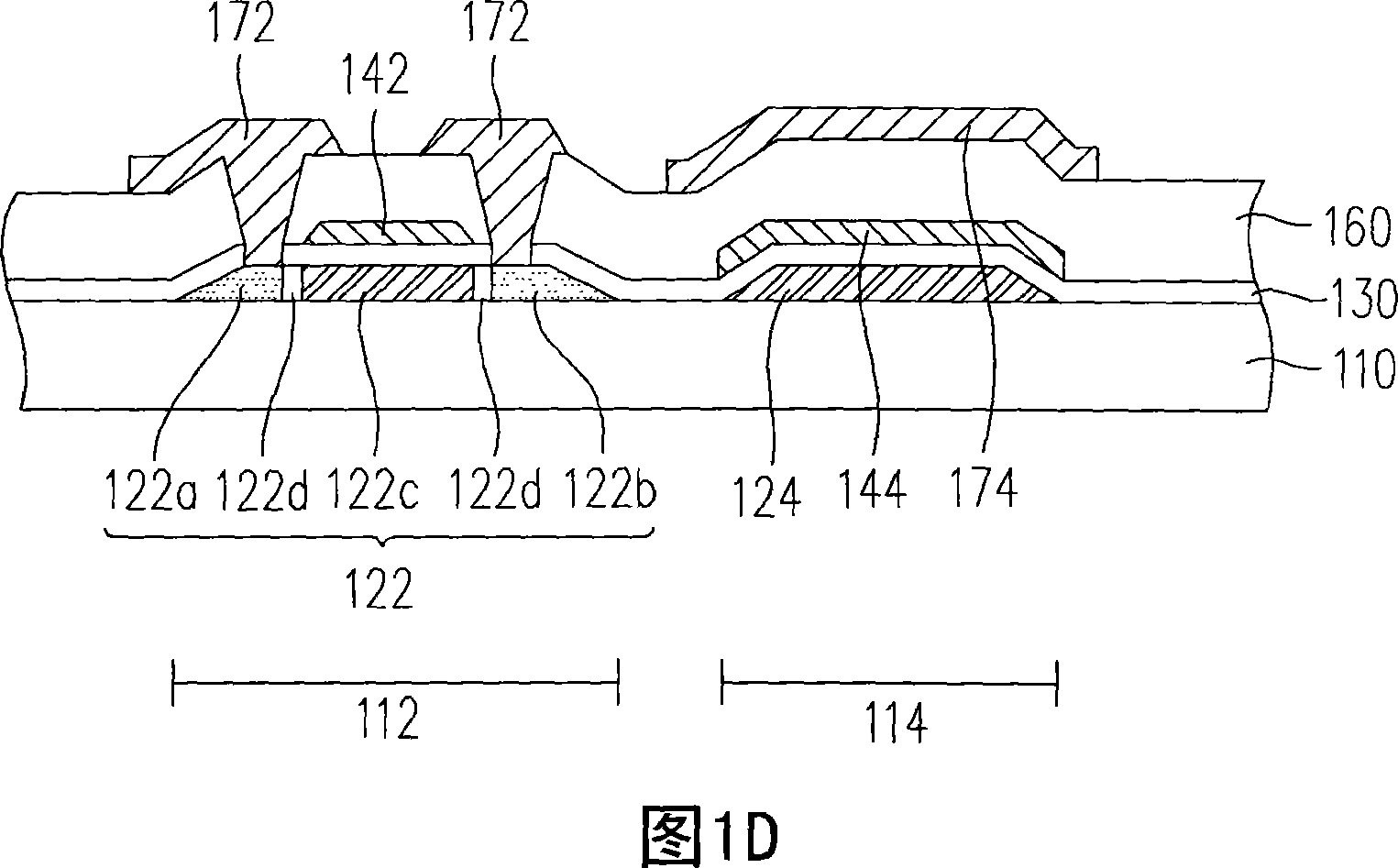

[0098] In order to improve the problem of insufficient storage capacity and reduce the amount of photomasks used in the fabrication of the semiconductor structure, the method for fabricating the semiconductor structure and the fabricated semiconductor structure, pixel structure and liquid crystal display panel according to the preferred embodiments of the present invention are proposed below. However, the following descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention.

[0099] Fabrication method of semiconductor structure

[0100] 2A to 2G are schematic cross-sectional flow diagrams of a method for fabricating a semiconductor structure according to a preferred embodiment of the present invention.

[0101] Referring to FIG. 2A , a semiconductor layer 220 is formed on the substrate 210 , and the semiconductor layer 220 is located in the active device region 212 and the storage capacitor region 214 of the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com