Process of separating acetylpropionic acid with active carbon

A technology of levulinic acid and activated carbon, which is applied in the field of adsorption and ion exchange separation and purification, can solve the problems of large consumption of extractant, high processing cost, and difficult separation of extracts, and achieve low production cost, easy industrialization, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

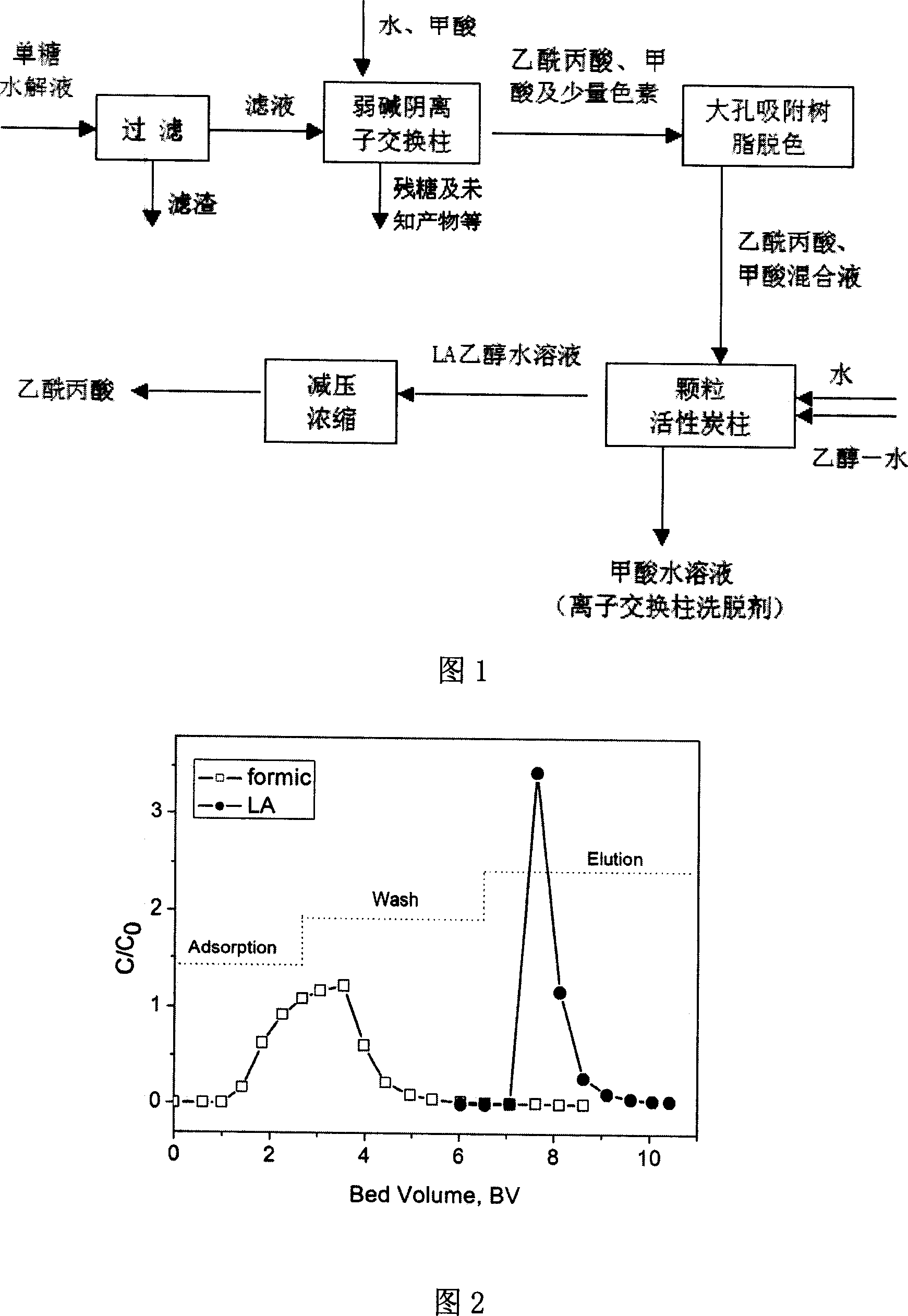

[0020] 300ml of a mixture of formic acid and levulinic acid (1.04mg / ml formic acid, 5.20mg / ml levulinic acid) with a mass ratio of 0.2:1 through 100ml bed volume at a flow rate of 3BV / h at 20°C Granular activated carbon column: After heating to 50°C, fully rinse the bed with deionized water at a flow rate of 3BV / h to desorb all formic acid adsorbed on the activated carbon. Then at the same temperature and at the same flow rate, the levulinic acid adsorbed on the activated carbon is eluted with a 95% ethanol aqueous solution. The elution curve of the entire separation process is shown in Figure 2. The eluate is concentrated under reduced pressure to obtain pure levulinic acid The purity of the product was 99.1% by HPLC, and the spectrum showed no miscellaneous peaks. The total yield of levulinic acid was 94.1%.

Embodiment 2

[0022] 200ml of a mixture of formic acid and levulinic acid (63.5mg / ml formic acid, 12.7mg / ml levulinic acid) with a mass ratio of 5:1 through 100ml bed volume at a flow rate of 0.5BV / h at 40°C The granular activated carbon column; after heating to 80℃, fully rinse the bed with deionized water at a flow rate of 0.5BV / h to desorb all the formic acid adsorbed on the activated carbon; then use 30% of the formic acid at the same flow rate at the same temperature The ethanol aqueous solution eluted the levulinic acid adsorbed on the activated carbon, and the eluate was concentrated under reduced pressure to obtain the pure levulinic acid. Detected by HPLC, its purity is 98.8%, the spectrum has no other peaks, and the total yield of levulinic acid is 96.5%.

Embodiment 3

[0024] 90ml of a mixture of formic acid and levulinic acid with a mass ratio of 1:1 (51.1mg / ml formic acid and 51.1mg / ml levulinic acid) was passed through a bed volume of 100ml at a flow rate of 1BV / h at 30°C Granular activated carbon column; after heating to 60℃, fully rinse the bed with deionized water at a flow rate of 1BV / h to desorb all formic acid adsorbed on the activated carbon; then use 80% methanol aqueous solution at the same temperature and at the same flow rate The levulinic acid adsorbed on the activated carbon is eluted. The purity of the obtained pure levulinic acid detected by HPLC was 99.3%, the spectrum showed no miscellaneous peaks, and the total yield of levulinic acid was 96.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com