Closed permeating waterproof fruit film bag

A highly breathable, fully enclosed technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

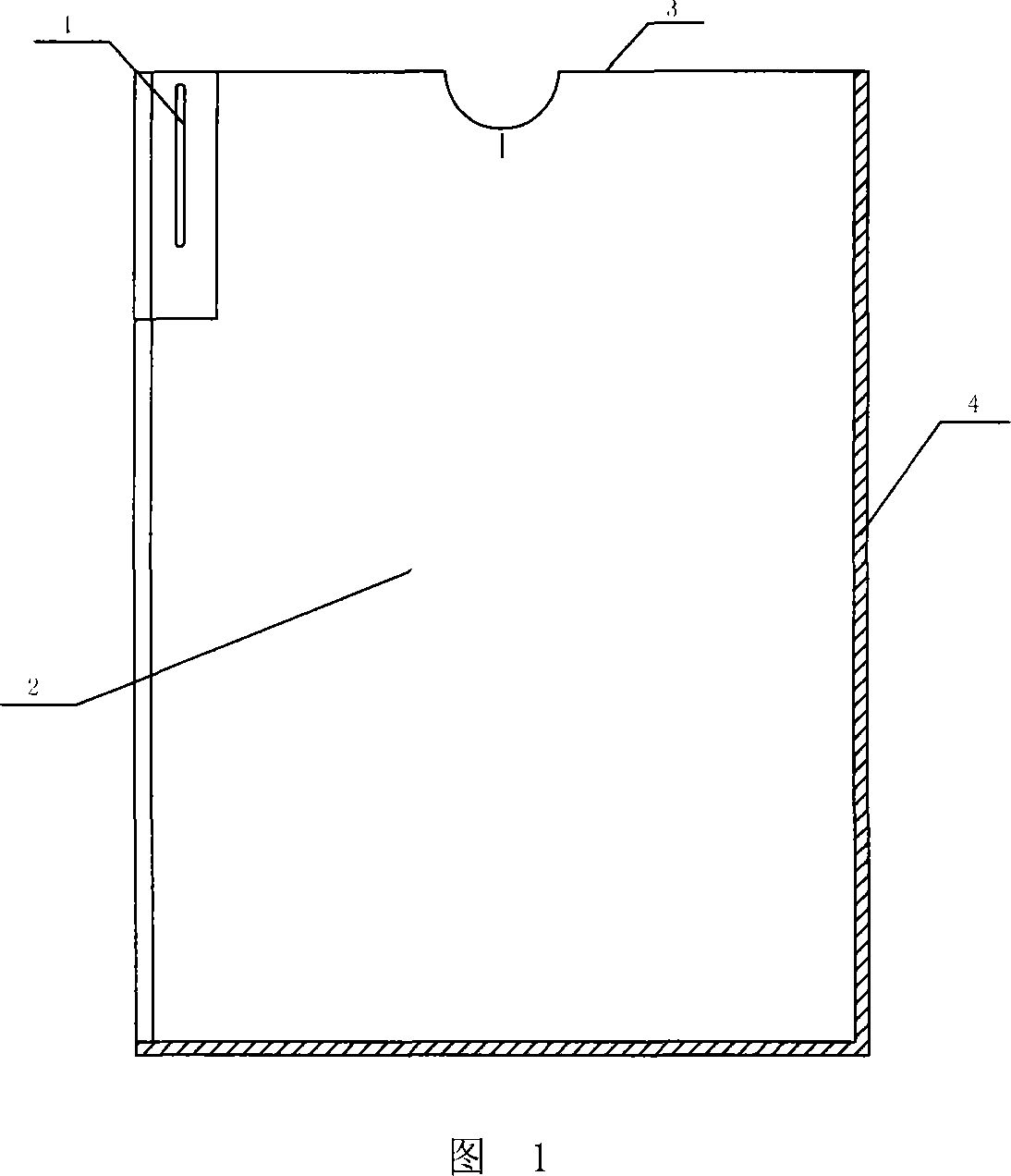

[0025]A kind of fully enclosed highly breathable waterproof film bag for fruit, one side of the film bag is provided with a binding wire 1 or a binding tape, and the film bag 2 is made of LDPE polyolefin resin, LLDPE polyolefin resin, copolymerized PP polyolefin resin, carbonic acid Calcium or talcum powder, coupling agent, modifier, and dispersant are raw materials that undergo coupling treatment, volume expansion and dispersion, banburying, extrusion and granulation, and then made at one time by a special plastic film bag making machine for fruit. A highly air-permeable casting film bag, the upper end 3 of the film bag is open, and the other end 4 is closed. The performance indicators of the finished product of the fruit fully enclosed highly breathable waterproof film bag are: melt flow rate ≥ 1.3g / 10min; relative density: 1.35±0.15g / cm3; water content ≤ 0.3%; cast film air permeability: 1000g / 24h.m2; cast film tensile strength (longitudinal / transverse)≥2N; cast film elong...

Embodiment 2

[0029] A kind of fully enclosed highly breathable waterproof film bag for fruit, one side of the film bag is provided with a binding wire 1 or a binding tape, and the film bag 2 is made of LDPE polyolefin resin, LLDPE polyolefin resin, copolymerized PP polyolefin resin, carbonic acid Calcium or talcum powder, coupling agent, modifier, and dispersant are raw materials that undergo coupling treatment, volume expansion and dispersion, banburying, extrusion and granulation, and then made at one time by a special plastic film bag making machine for fruit. A highly air-permeable casting film bag, the upper end 3 of the film bag is open, and the other end 4 is closed. The performance indicators of the finished product of the fruit fully enclosed highly breathable waterproof film bag are: melt flow rate ≥ 1.3g / 10min; relative density: 1.35±0.15g / cm3; water content ≤ 0.3%; cast film air permeability: 4000g / 24h.m2; cast film tensile strength (longitudinal / transverse)≥2N; cast film elon...

Embodiment 3

[0033] A kind of fully enclosed highly breathable waterproof film bag for fruit, one side of the film bag is provided with a binding wire 1 or a binding tape, and the film bag 2 is made of LDPE polyolefin resin, LLDPE polyolefin resin, copolymerized PP polyolefin resin, carbonic acid Calcium or talcum powder, coupling agent, modifier, and dispersant are raw materials that undergo coupling treatment, volume expansion and dispersion, banburying, extrusion and granulation, and then made at one time by a special plastic film bag making machine for fruit. A highly air-permeable casting film bag, the upper end 3 of the film bag is open, and the other end 4 is closed. The performance indicators of the finished product of the fruit fully enclosed highly breathable waterproof film bag are: melt flow rate ≥ 1.3g / 10min; relative density: 1.35±0.15g / cm3; water content ≤ 0.3%; cast film air permeability: 2000g / 24h.m2; cast film tensile strength (longitudinal / transverse)≥2N; cast film elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com