A kind of non-woven fabric with two-component gradient structure for water filtration and its preparation method and application

A gradient structure, non-woven fabric technology, applied in the field of non-woven fabrics, can solve the problems of short service life, low filtration accuracy, single structure, etc., and achieve the effects of long service life, high filtration accuracy, and improved filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

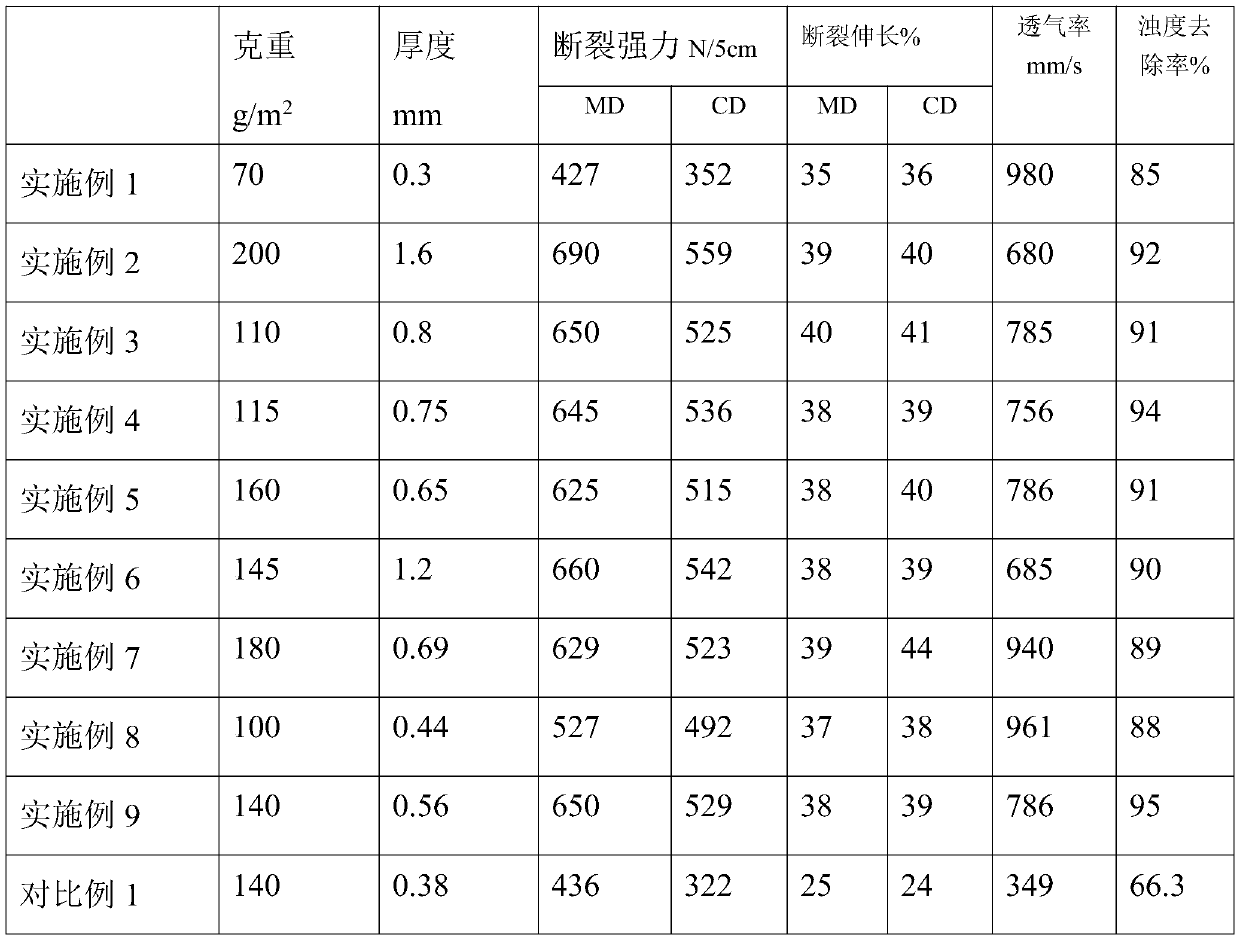

Examples

preparation example Construction

[0030] The present invention also includes a method for preparing a nonwoven fabric with a two-component gradient structure for water filtration, comprising the following steps:

[0031] ①PET and COPET are pre-crystallized, sliced and dried to obtain PET slices and COPET slices;

[0032] ②The PET chips and COPET chips obtained in step ① are melted and accumulated, spun, cooled, drawn and divided into a web through the first group of spinning components to obtain the first layer of fiber web;

[0033] ③The PET slices and COPET slices obtained in step ① are melted and accumulated, spun, cooled, drawn and divided into a web through the second group of spinning components to obtain the second layer of fiber web;

[0034] ④ Lay the second layer of fiber web obtained in step ③ on the first layer of fiber web obtained in step ②, superimpose to obtain a composite fiber web, and then bond the composite fiber web with hot air to obtain a two-component gradient nonwoven fabric for wate...

Embodiment 1

[0040] A non-woven fabric with a two-component gradient structure for water filtration, consisting of a first layer of fiber web and a second layer of fiber web bonded together, wherein the first layer of fiber web is made of trilobal PET with a linear density of 6D. Silk fibers and circular COPET filament fibers with a linear density of 4D, and trilobal PET filament fibers account for 70% of the quality of the first layer of web; the second layer of web is made of trilobal PET with a linear density of 2D The filament fiber and the circular COPET filament fiber with a linear density of 1D are composed, and the trilobal PET filament fiber accounts for 70% of the mass of the second layer of fiber web.

Embodiment 2

[0042] A non-woven fabric with a two-component gradient structure for water filtration, consisting of a first layer of fiber web and a second layer of fiber web bonded together, wherein the first layer of fiber web is made of trilobal PET with a linear density of 6D. Silk fibers and circular COPET filament fibers with a linear density of 1D, and trilobal PET filament fibers account for 95% of the quality of the first layer of web; the second layer of web is made of trilobal PET with a linear density of 6D The filament fiber and the circular COPET filament fiber with a linear density of 4D are composed, and the trilobal PET filament fiber accounts for 95% of the quality of the second layer of fiber web.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com