Filter cloth for producing white carbon black

A technology of filter cloth and white carbon black, which is applied in the direction of filtration and separation, fabric, textile, etc., can solve the problems of low filter cloth strength, high labor cost, and small air permeability, so as to reduce adhesion, reduce price, and increase air permeability volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

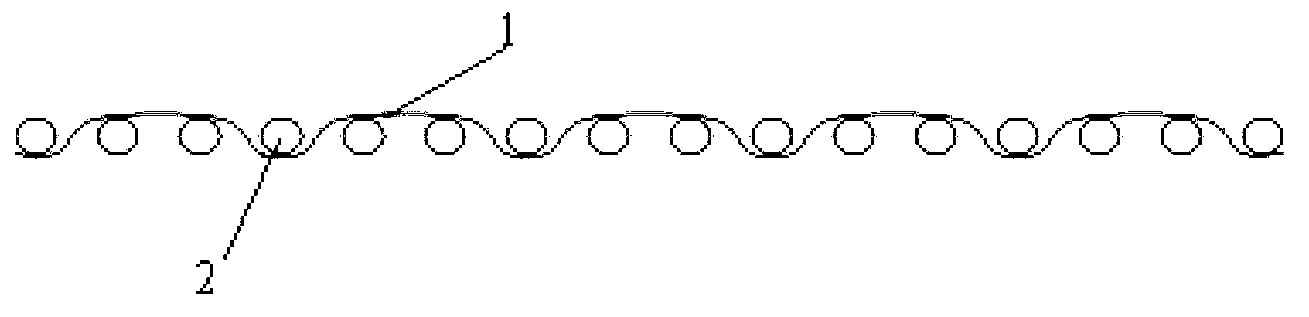

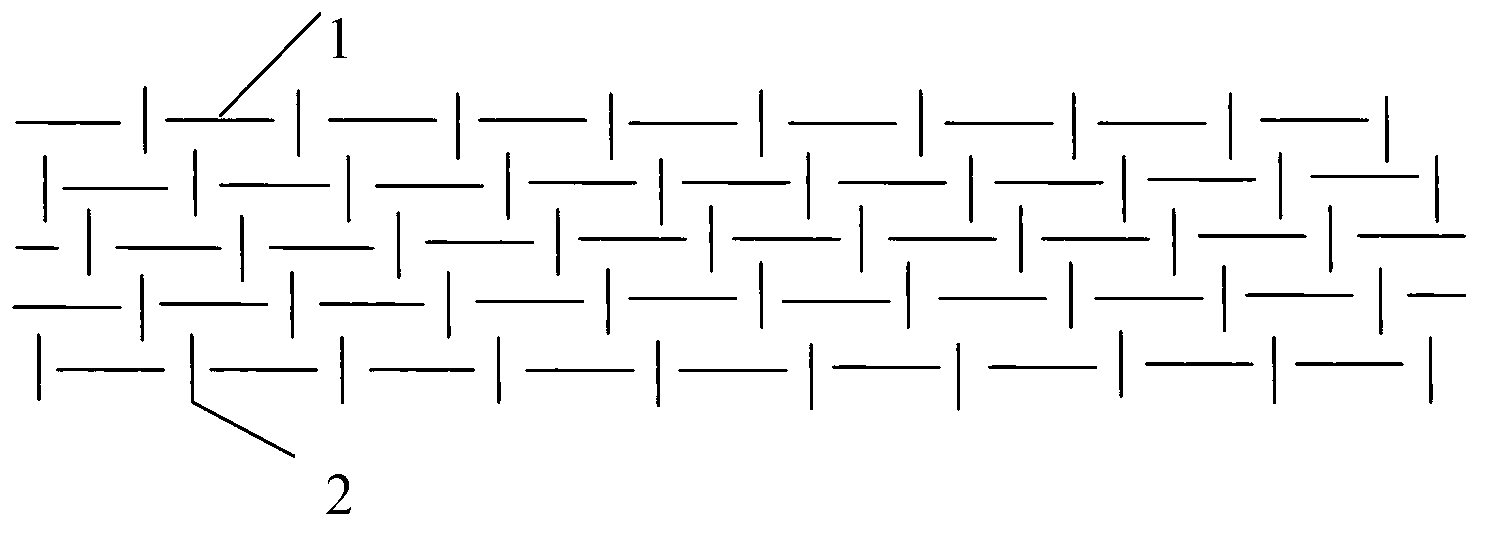

[0020] Such as figure 1 with figure 2 As shown, the filter cloth used in the production of white carbon black provided by the present invention is woven by warp 2 and weft 1, the warp 2 is multifilament, and the weft 1 is monofilament. Among the warp and latitude intersections of the cloth, the number of warp and latitude intersections where the weft 1 is above the warp 2 is greater than the number of warp and latitude intersections where the weft is below the warp.

[0021] In this way, the top of the filter cloth can be used as a filter surface, and the bottom of the filter cloth can be used as a non-filter surface. There are many weft threads 1 arranged on the filter cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com