Method of purifying calcium carbide furnace gas

A technology of calcium carbide furnace gas and calcium carbide furnace, which is applied in the direction of combustible gas purification, combustible gas purification/retrofit, gas dust removal, etc., and can solve problems such as large water consumption, sticky pipes, smaller pipe diameters, and affecting furnace gas transportation. , achieve cost reduction, low water consumption, reduce floor area and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

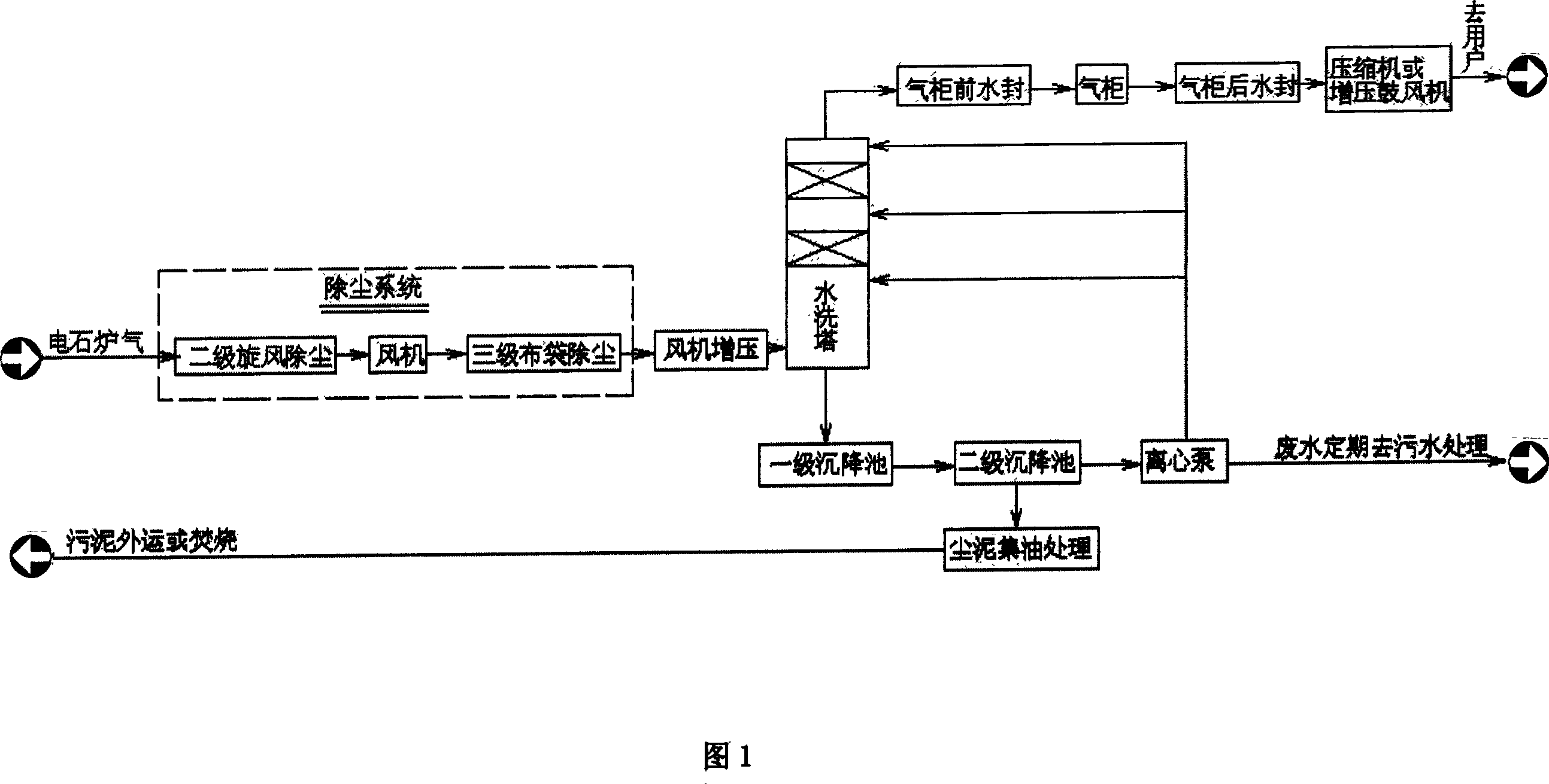

[0018] A method for purifying calcium carbide furnace gas, comprising the following steps: (1) dissolving the tar-containing 150~600mg / Nm from the calcium carbide furnace 3 , Dust 100~150g / Nm 3 After the high-temperature furnace gas passes through the dust removal system, the temperature drops to 225°C (dry dust removal). The dust removal system consists of a secondary cyclone dust collector, a fan, and a three-stage bag filter. The high-temperature furnace gas passes through the secondary cyclone dust collector, Fan, three-stage bag filter; (2) The cooled furnace gas is boosted to 10KPaG by a high-temperature fan, and sent to a water washing tower for washing, so that the temperature of the furnace gas drops to 20°C, the tar content drops to 1-100ppm, and the dust content Reduced to 1~5mg / Nm 3 (wet purification); (3) The furnace gas washed from the water washing tower passes through the water seal in front of the gas cabinet, the spiral wet gas cabinet, and the water seal be...

Embodiment 2

[0021] A method for purifying calcium carbide furnace gas, comprising the following steps: (1) dissolving the tar-containing 150~600mg / Nm from the calcium carbide furnace 3 , Dust 100~150g / Nm 3 After the high-temperature furnace gas passes through the dust removal system, the temperature drops to 260°C. The dust removal system is composed of a secondary cyclone dust collector, a fan, and a third-stage bag filter. The high-temperature furnace gas passes through the secondary cyclone dust collector, fan, and third-stage dust collector in turn. Bag dust collector; (2) The cooled furnace gas is boosted to 25KPaG by a high-temperature fan, and sent to a water washing tower for washing, so that the temperature of the furnace gas is reduced to 50°C, the tar content is reduced to 1-100ppm, and the dust content is reduced to 1-100ppm 5mg / Nm 3 (3) The furnace gas washed from the water washing tower will pass through the water seal before the gas holder, the spiral wet type gas holder, ...

Embodiment 3

[0023] A method for purifying calcium carbide furnace gas, comprising the following steps: (1) dissolving the tar-containing 150~600mg / Nm from the calcium carbide furnace 3 , Dust 100~150g / Nm 3 After the high-temperature furnace gas passes through the dust removal system, the temperature drops to 240°C, and the dust removal system adopts a conventional dust removal system; (2) The cooled furnace gas is boosted to 20KPaG by a high-temperature fan, and sent to a water washing tower for washing, so that the furnace gas The temperature drops to 35°C, the tar content drops to 1-100ppm, and the dust content drops to 1-5mg / Nm 3 (3) The furnace gas washed from the water washing tower will pass through the water seal before the gas holder, the spiral wet type gas holder, and the water seal after the gas holder in turn to make purified calcium carbide furnace gas. According to the length of the distance, the purified calcium carbide furnace gas is sent to the user after being boosted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com