Method of preparing zinc oxide doped ambient temperature diluted magnetic semi-conducting material

A technology of dilute magnetic semiconductor and zinc oxide is applied in the field of new semiconductor spintronic materials and device preparation, which can solve the problems of inconsistency and magnetic indeterminacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

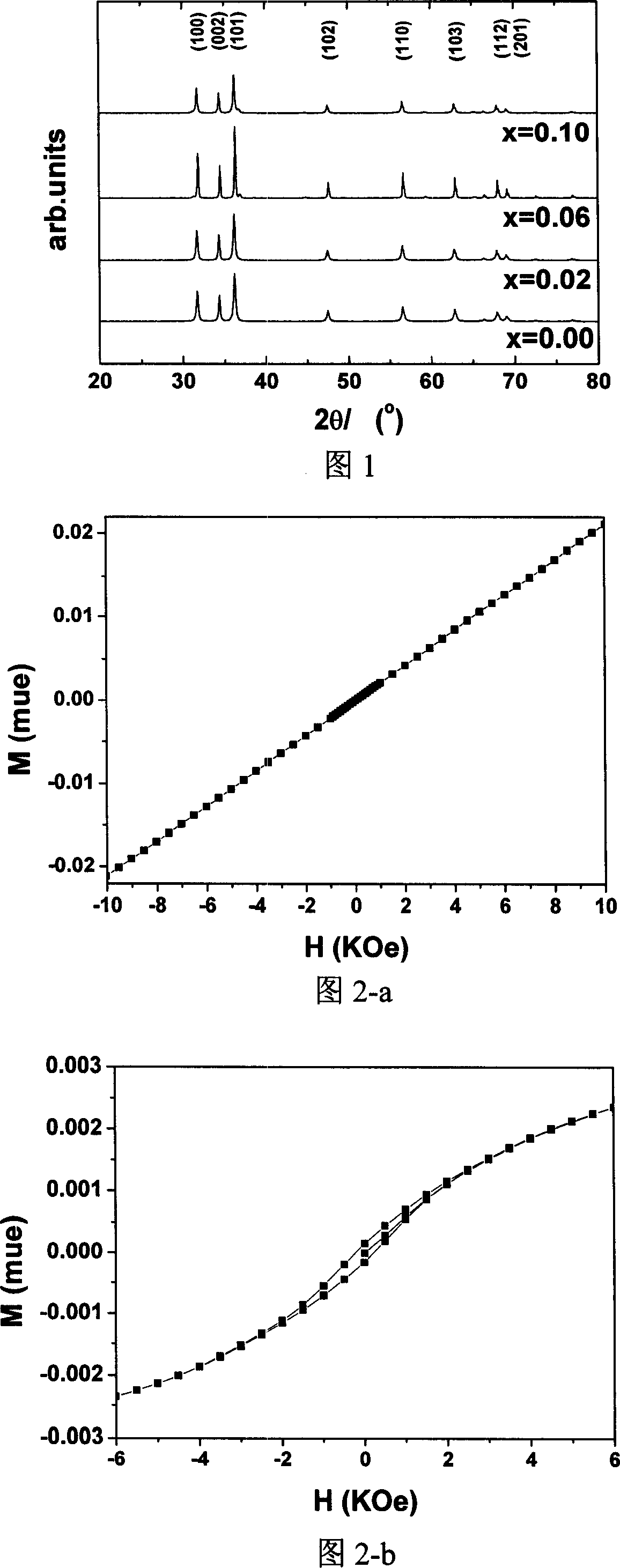

[0015] Example 1 Preparation of room temperature dilute magnetic semiconductor Co x Zn 1-x O(x=0.06) material

[0016] Preparation of room temperature dilute magnetic semiconductor Co by solid-state reaction method combined with special atmosphere post-annealing process x Zn 1-x O material. Use (analytical pure) zinc oxide powder and tricobalt tetroxide powder (Co:Zn molar ratio is 6:94), weigh the two oxides with an electronic balance according to the required molar ratio, put them into a ball-milled agate jar and add an appropriate amount of Ionized water and agate balls, at room temperature, use a planetary ball mill for long-term wet ball milling (60 hours), so that the particle size of zinc oxide and cobalt tetroxide is further reduced and uniformly mixed, and then dried at 100 ° C to form a uniform of mixed materials. Pre-sintering was carried out in an air atmosphere, and the temperature was set at 1000°C for 12 hours of reaction sintering to fully react the mixtur...

Embodiment 2

[0018] Example 2 Preparation of room temperature dilute magnetic semiconductor Co x Zn 1-x O(x=0.01) material

[0019] Use (analytical pure) zinc oxide powder (ZnO) and cobalt trioxide powder (Co 2 o 3 ) whose Co:Zn molar ratio is 1:99, the two oxides are weighed with an electronic balance according to the required molar ratio, put into a ball-milled agate tank and add an appropriate amount of deionized water and agate balls, at room temperature, use a planetary formula The ball mill is used for long-time ball milling to further reduce the particle size of zinc oxide and cobalt trioxide powder and mix them fully and uniformly, and then dry them at less than 100°C to form a uniform mixed material. Pre-sintering by reaction in an air atmosphere, the temperature is set at 800-1000 ° C for 4-12 hours of reaction sintering, so that the mixture is fully reacted; Co 0.01 Zn 0.99 O material, then pressed into pellets, cured and sintered using the same temperature as reactive sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com