Multiple-pass self-regulating loop heat pipe device

A loop heat pipe and self-regulating technology, applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of inaccurate and flexible temperature control, inability to self-regulate well, and achieve obvious self-regulating ability and maximum The effect of enhanced heat transfer capacity and improved overall pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

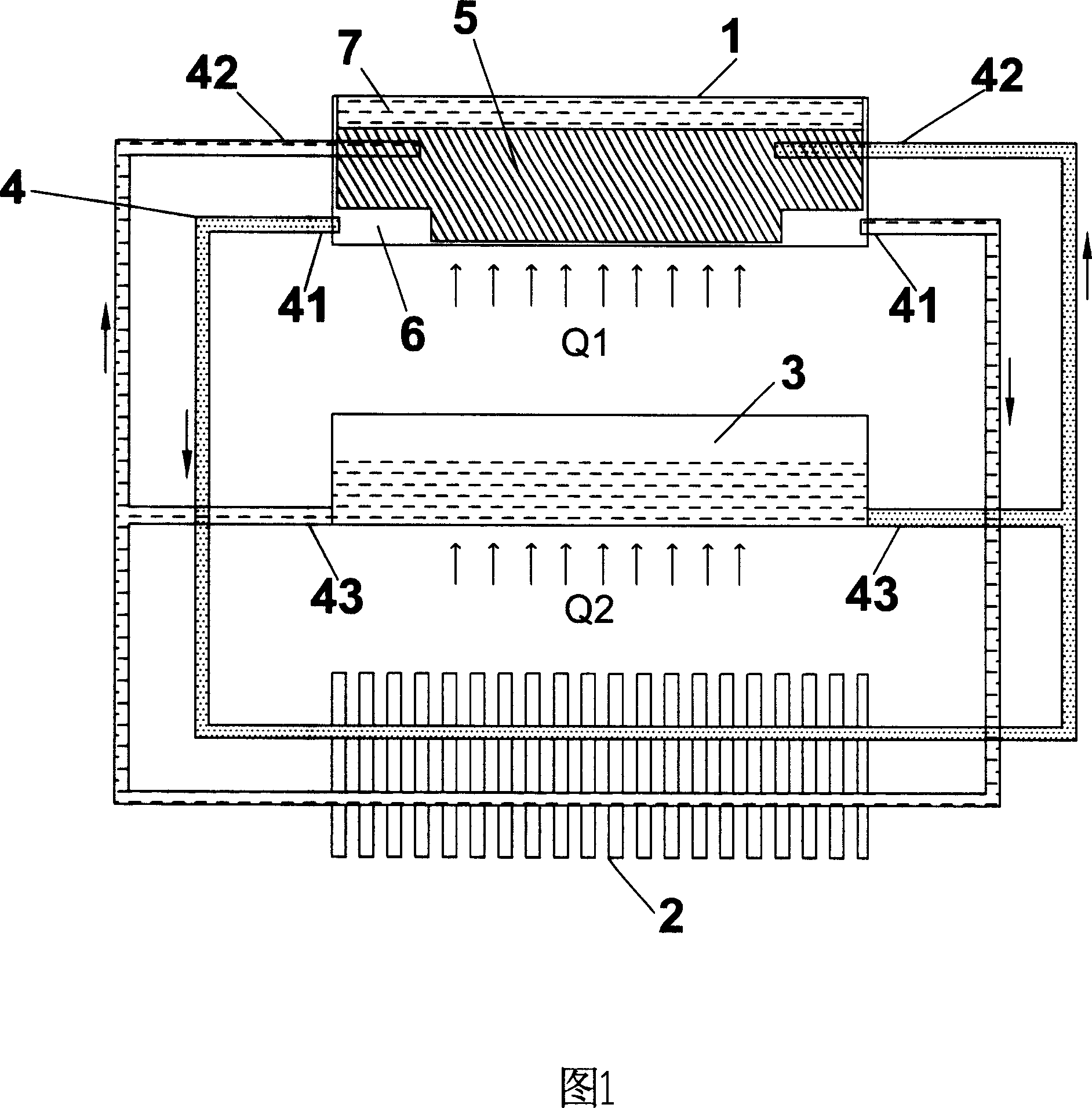

[0025] Embodiment 1 Using a flat-plate multi-channel self-regulating loop heat pipe device to dissipate heat from a computer CPU

[0026] As shown in Figure 1, a multi-channel self-regulating loop heat pipe device includes an evaporator 1, a condenser 2, a compensator 3 and at least two loop pipes 4; An evaporation chamber 6 is formed between the core 5 and the inner wall of the evaporator 1; the vapor inlet port 41 of the loop pipe 4 communicates with the evaporation chamber 6, the loop pipe 4 passes through the condenser 2, and the return outlet port 42 of the loop pipe 4 communicates with the evaporation chamber 6. The liquid-absorbing core 5 in the device 1 is connected, and the return section 43 of the loop pipe 4 is also connected with the compensator 3, and the compensator 3 is filled with working liquid.

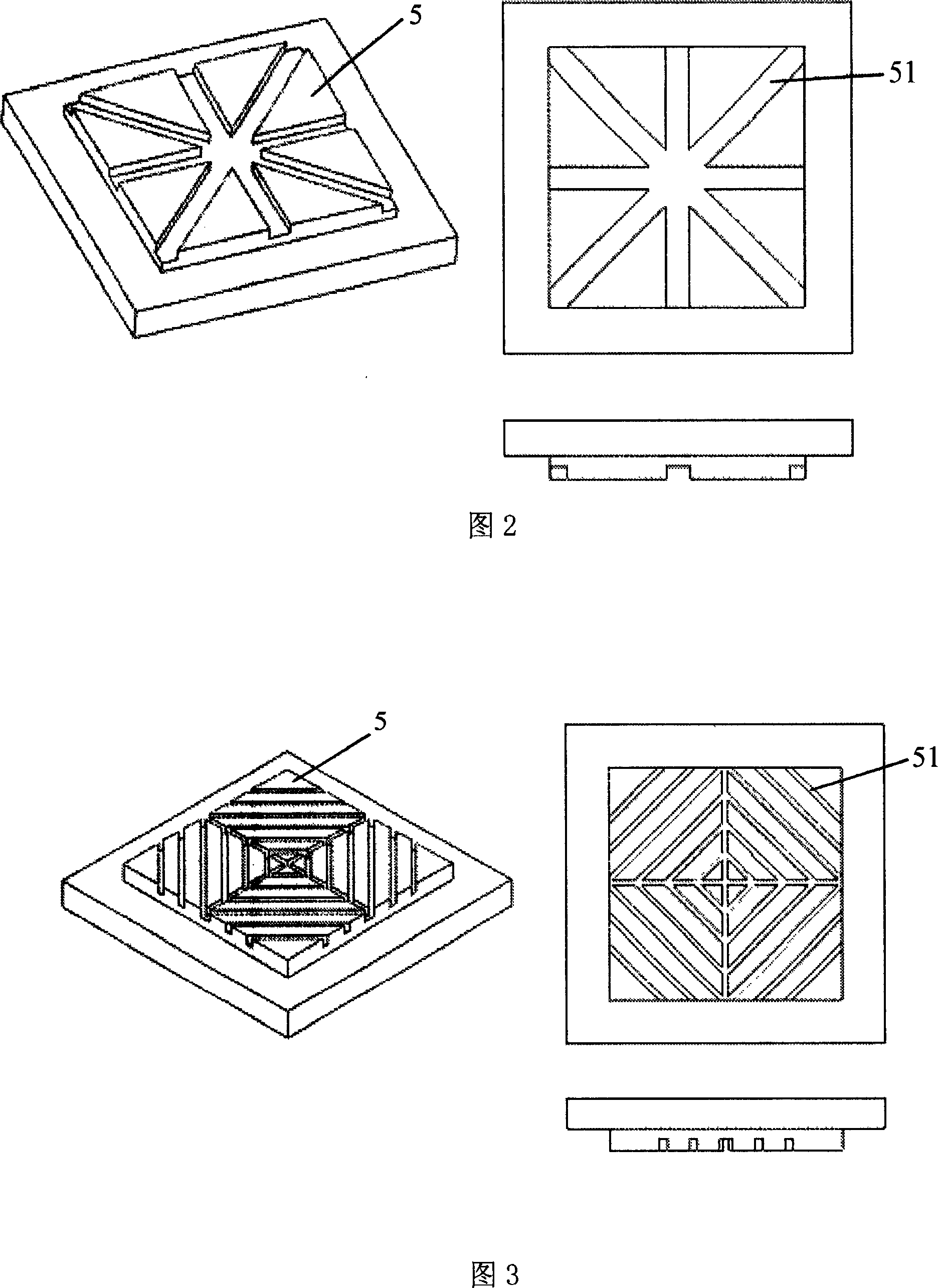

[0027] As a preference, the liquid-absorbing core 5 is designed as a boss structure, and there are positive "V-shaped" or "reverse-V-shaped" channels 51 that communi...

Embodiment 2

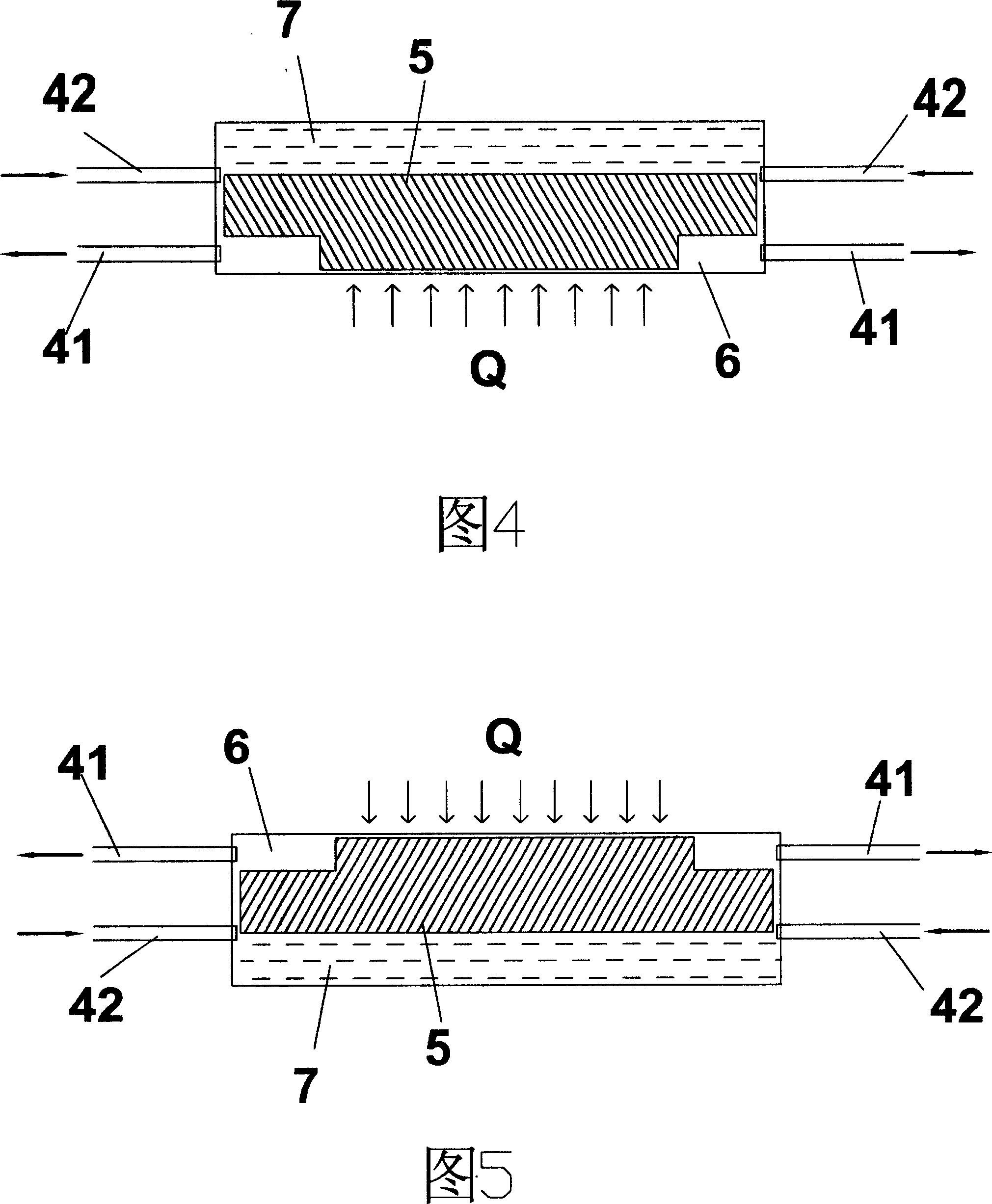

[0031] Embodiment 2 Anti-gravity heat dissipation effect of flat plate multi-channel self-regulating loop heat pipe device

[0032] In Fig. 4, when the heat source that needs to dissipate heat is located at the lower part of the evaporator 1, the bottom of the evaporator 1 is in contact with the heat load end Q, the working fluid in the liquid-absorbing core 5 will absorb latent heat, and steam will be generated in the channel 51. The steam finally gathers into the lower evaporation chamber 6, and then reaches the condenser 2 along the loop pipe 4 to be cooled into liquid according to the respective resistance distribution, releases latent heat, and the liquid flows back to the evaporator 1, so as to achieve the purpose of taking away the heat. The suction force of the liquid backflow comes from the liquid suction capacity of the liquid-absorbing core 5 and the gravity effect of the liquid itself.

[0033] In Fig. 5, when the heat source that needs to dissipate heat is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com