Preparing method of zinc oxide nano fiber film used as photocatalyst

A technology of zinc oxide nanometer and photocatalyst, which is applied in the field of nanomaterials and can solve problems such as nanofibers that have not been tried or involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Dissolve 20 grams of cellulose acetate and 5 grams of zinc acetate in 75 grams of dimethylformamide / acetone mixed solvent prepared in a ratio of 1:1 (v / v).

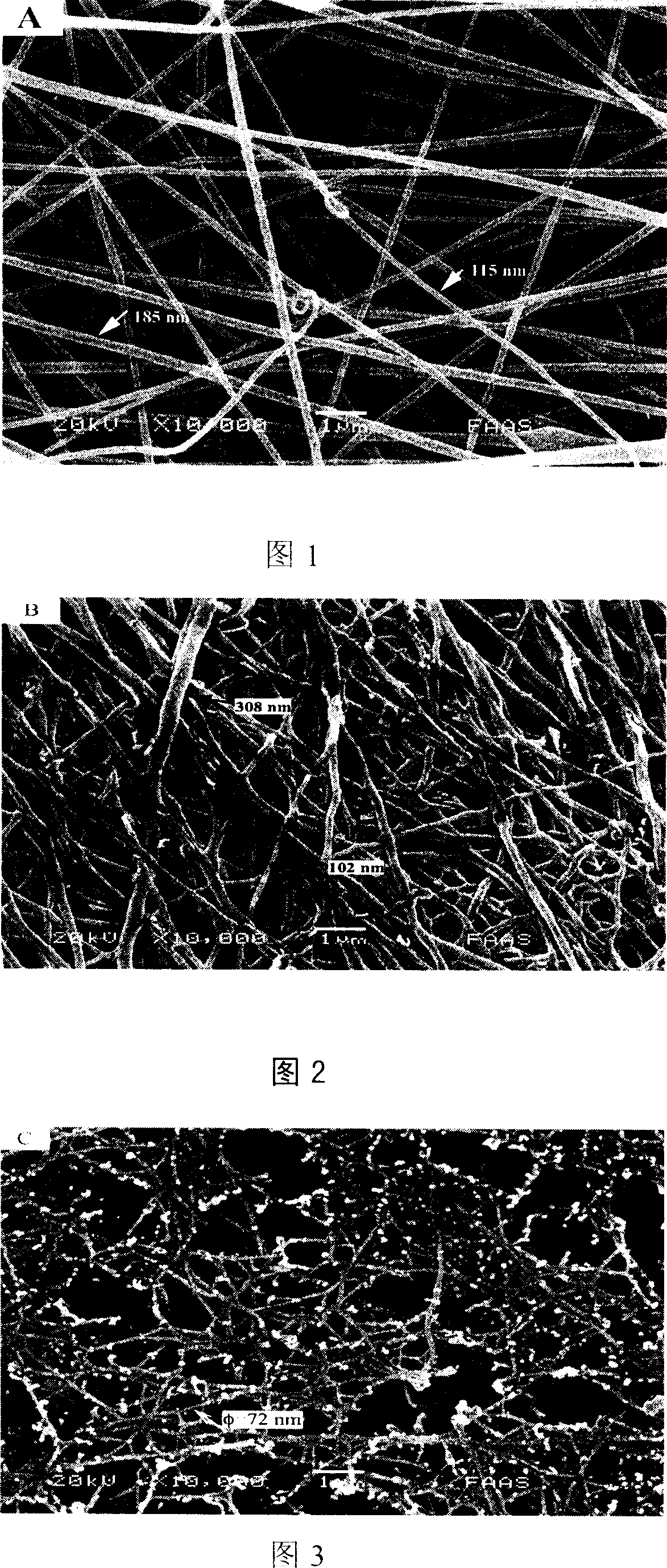

[0037] 2. Prepare a zinc acetate / cellulose acetate composite nanofiber membrane with a diameter of 110-80 nm through electrospinning equipment with a power supply voltage of 10 kV.

[0038]3. Put the zinc acetate / cellulose acetate composite nanofiber into 0.1N NaOH aqueous solution to hydrolyze for 12 hours, then wash and dry. The dried composite nanofiber membrane was calcined in air at 500° C. for 5 hours to obtain a ZnO nanofiber membrane with a diameter of about 80 nanometers.

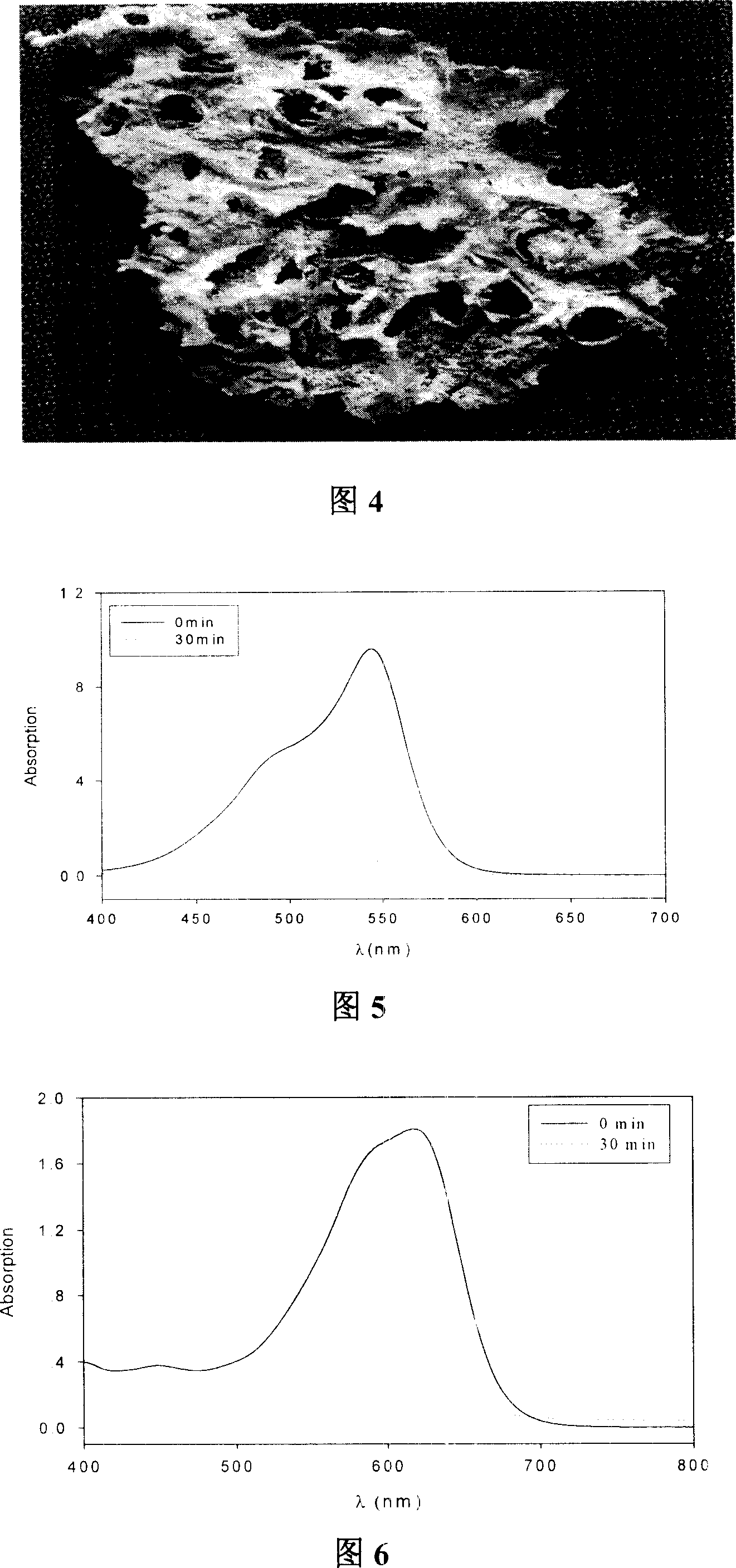

[0039] 5. Put 5 mg of ZnO nanofibers into 10 ml of 47 ppm dye acid fuchsin solution, and magnetically stir for 30 min under sunlight. The dye concentration in the assay solution was 0.98 ppm.

Embodiment 2

[0041] 1. Dissolve 15 grams of cellulose acetate and 8 grams of zinc acetate in 77 grams of dimethylformamide / acetone mixed solvent prepared in a ratio of 3:1 (v / v).

[0042] 2. Through the electrospinning equipment, the power supply voltage is adjusted to 22kV, and the zinc acetate / cellulose acetate composite nanofiber membrane with a diameter of 100-150nm is prepared.

[0043] 3. Put the zinc acetate / cellulose acetate composite nanofiber into 0.1N NaOH aqueous solution to hydrolyze for 24 hours, then wash and dry. The dried composite nanofibers were calcined in air at 470° C. for 6 hours to obtain a ZnO nanofiber film with a diameter of about 50 nm.

[0044] 5. Put 5 mg of ZnO nanofibers into 10 ml of 45 ppm dye amino black B solution, and magnetically stir for 30 min under sunlight. The dye concentration in the assay solution was 4.7 ppm.

Embodiment 3

[0046] 1. Dissolve 15 grams of cellulose acetate and 10 grams of zinc acetate in 75 grams of dimethylformamide / acetone mixed solvent prepared in a ratio of 1:2 (v / v).

[0047] 2. Through electrospinning equipment, the power supply voltage is 15kV, and the zinc acetate / cellulose acetate composite nanofiber membrane with a diameter of 110-180nm is prepared.

[0048] 3. Put the zinc acetate / cellulose acetate composite nanofiber into 0.1N NaOH aqueous solution to hydrolyze for 18 hours, then wash and dry. The dried composite nanofiber membrane was calcined in air at 550° C. for 7 hours to obtain a ZnO nanofiber membrane with a diameter of about 80 nanometers.

[0049] 5. Put 5 mg of ZnO nanofibers into 10 ml of 47 ppm dye acid fuchsin solution, and magnetically stir for 30 min under sunlight. The dye concentration in the assay solution was 2.3 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com