Vertical film flash distillation rectifying still for producing bio diesel fuel

A biodiesel and rectifying still technology, applied in flash evaporation, biological raw materials, biofuels, etc., can solve the problems of lower product yield, increase of distillation residue, prolonged residence time, etc., to improve heat utilization rate, reduce Grease loss, effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

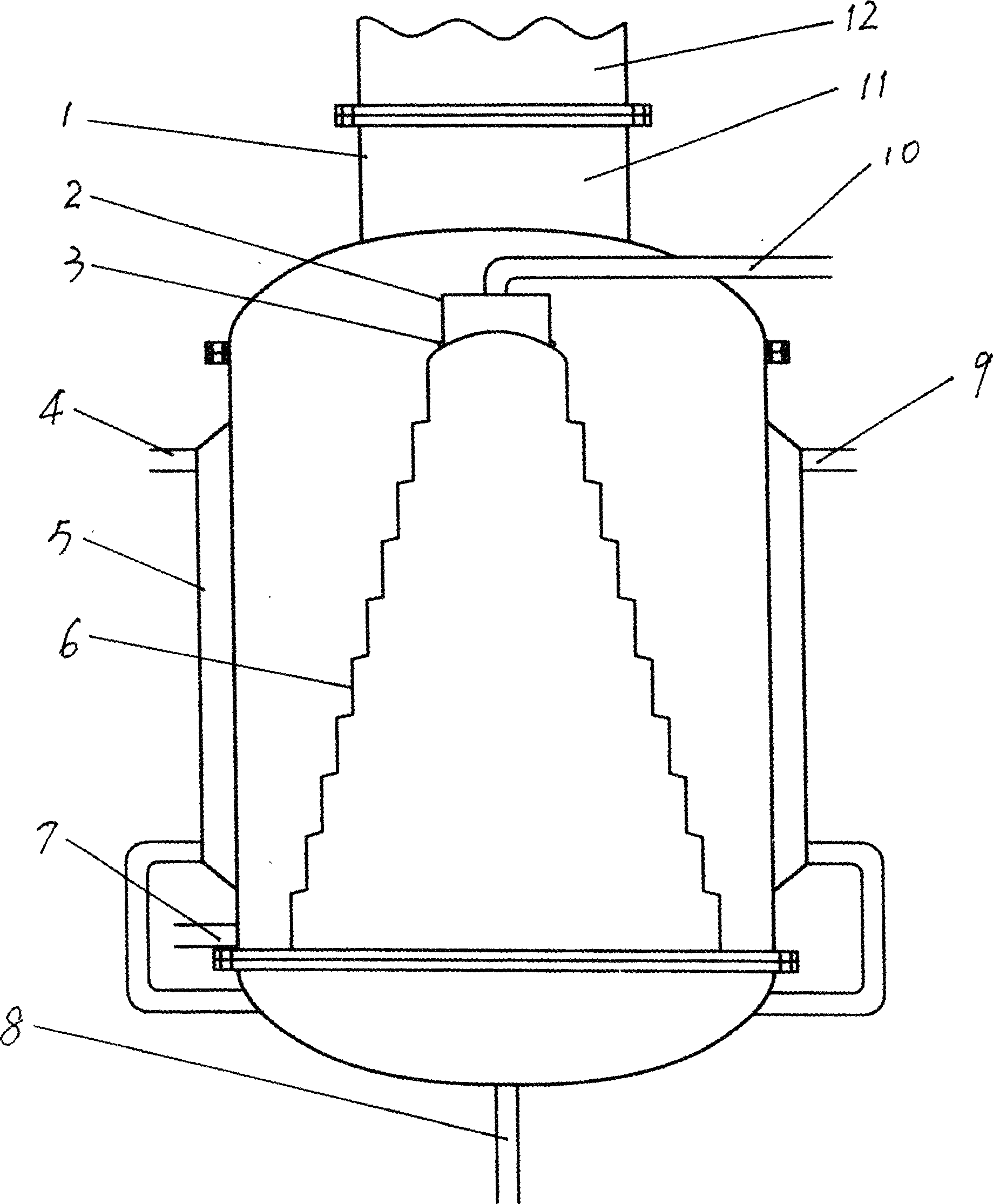

[0007] Structure of the present invention is as shown in accompanying drawing, is that the A3 steel plate of 10mm is welded a diameter 1200mm with thickness, the rectifying kettle 1 of high 4500mm, design pressure is 10kg / cm 2 , the production capacity is 3T / h. A tower-shaped thin-film evaporator 6 is designed in the rectification kettle 1, and the jacket 5 around the outer wall of the rectification kettle 1 and the thin-film evaporator 6 are heat-conducting oil, and the heat-conducting oil inlets 4 and 9 are located on the upper part of the jacket 5 , the heating area is 40m 2 , the heating temperature is 300°C; a flow limiter 2 is set on the top of the tower thin film evaporator 6, and a plurality of small holes 3 are arranged around the bottom of the flow limiter 2, and the upper part of the flow limiter 2 is connected to the crude methyl ester inlet 10; The ester steam outlet 11 is arranged on the top of the rectifying kettle 1 and connected to the condenser interface 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com